- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

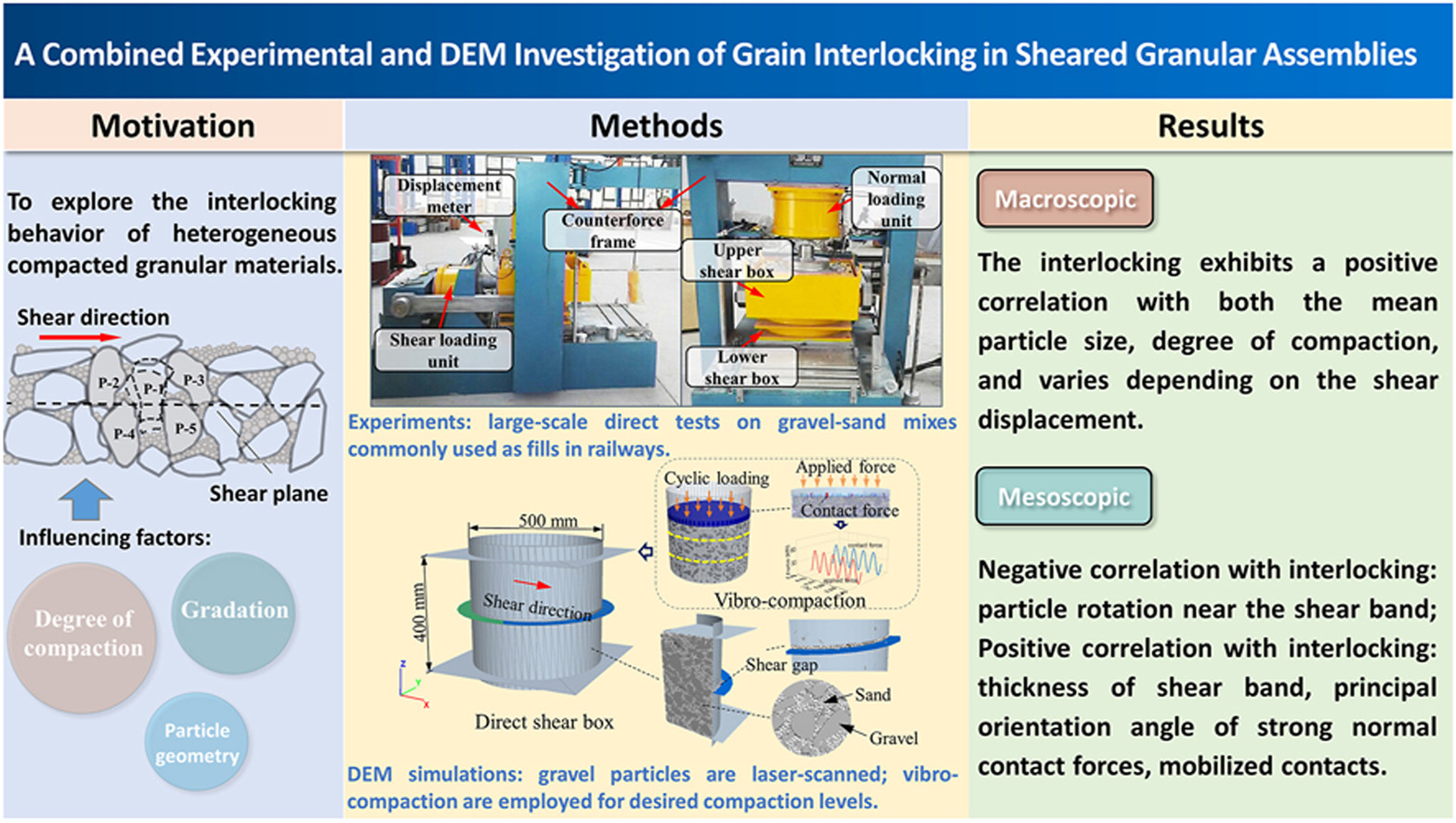

• Investigates shear behavior in gravel−sand mixes through large-scale direct shear tests and DEM simulations.

• Explores the impact of gradation and compaction on shear stress and granular interlocking.

• Utilizes DEM to provide authentic meso-scale insights into shear resistance mechanisms.

• Identifies the role of particle size and compaction in enhancing granular interlocking.

• Reveals strain-hardening under subsequent shear reversal for different degrees of compaction.

Compacted granular material, integral to geotechnical engineering, undergoes translation, rotation, and interlocking when subject to shear displacements or external loads. The present study focuses on the interlocking of heterogeneous granular materials, a complex behavior influenced by gradation, compaction, and varying particle geometry, and has consequently received limited attention in existing research. To address this research gap, we conducted an analysis on the effect of grain interlocking on the shear resistance of granular assemblies, using a combination of laboratory testing and the discrete element method (DEM). Initially, large-scale direct shear tests were conducted on gravel−sand mixes with varying degrees of compaction and normal pressure. One of the mixes also underwent subsequent shear reversal to explore the differences in grain interlocking between the two shearing processes on the shear plane. After analyzing the laboratory results, a mesoscopic scale investigation was performed by replicating the test using discrete element simulations. To facilitate this, granular particle geometries were measured using 3D laser scanning based on the physical lab tests. Subsequently, based on these scans, discrete element R-block and ball models were utilized to construct both the coarse and fine particles within the mix. Surface vibro-compaction was employed to regulate the degree of compaction. The results indicate that an increase in vertical pressure, coupled with a zero dilatancy angle, results in a rising stress ratio, indicative of grain interlocking. This interlocking exhibits a positive correlation with both the coarse content and the degree of compaction, and varies depending on the shear displacement. As interlocking progresses, the shear band, induced by particle movement, expands and is associated with reduced particle rotation near the shear band. The study further reveals a consistent positive correlation between interlocking and the principal orientation angle of strong normal contact forces, as well as a correlation between interlocking and mobilized contacts.