- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

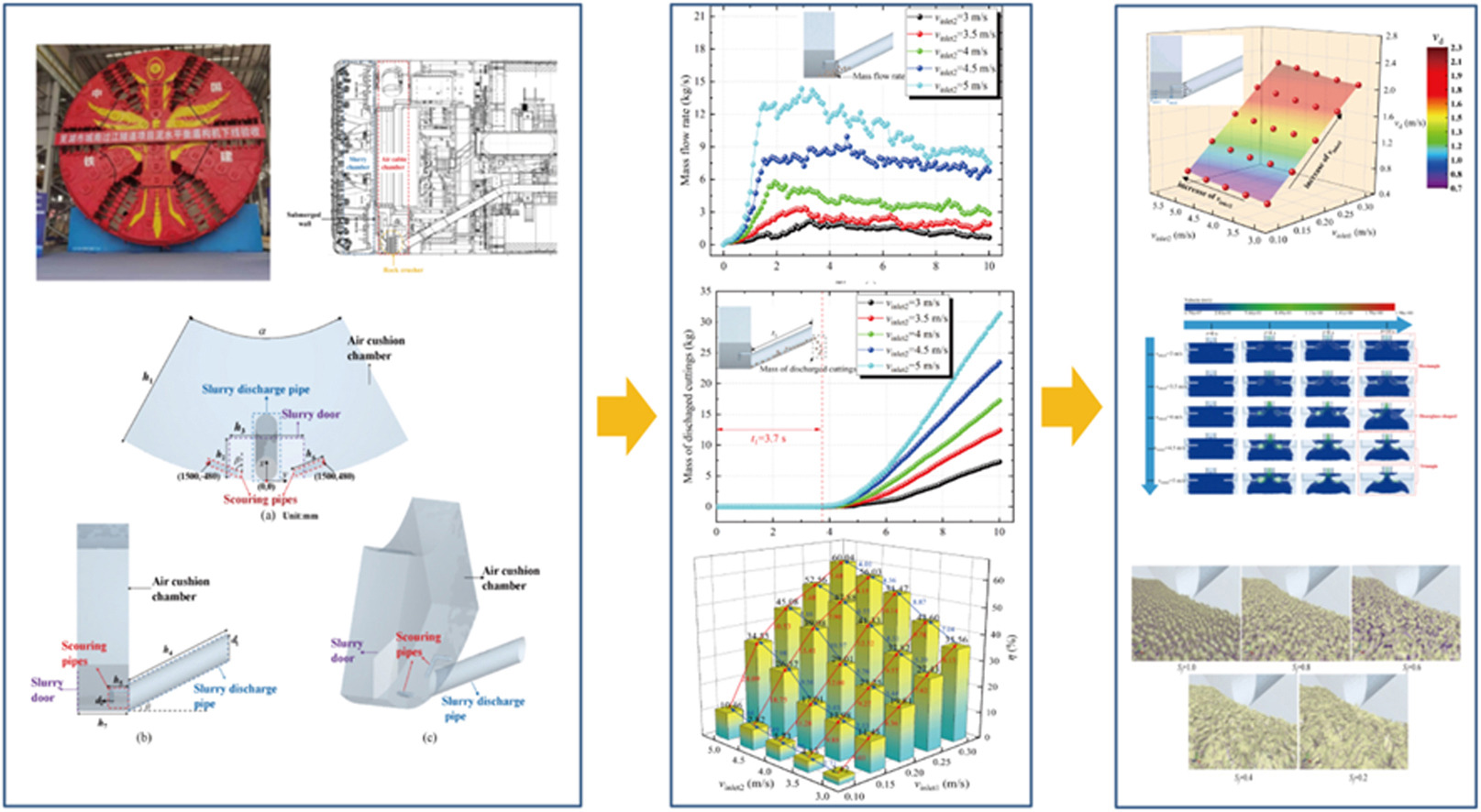

• A numerical model completely reflecting cuttings discharge process is established based on CFD-DEM coupling method.

• Effects of various factors on cuttings discharge are investigated.

• Reasons for the effects of each factor are analyzed.

• Relevant suggestions for practical engineering are provided.

The rapid discharge of cuttings from the air cushion chamber is crucial for the construction safety and excavation efficiency of the slurry shield. Previous studies have mainly focused on the transport characteristics of cuttings in the slurry discharge pipe, while the complete process of cuttings entering the slurry discharge pipe from the air cushion chamber until they are discharged was often overlooked. Based on the CFD-DEM coupling method and combined with actual engineering, this paper established a numerical model that can more completely reflect the cuttings discharge process during slurry shield tunneling, and the effects of the slurry velocity at slurry gate and scouring pipes, inclination angle of slurry discharge pipe, cuttings diameter and shape coefficient were investigated by analyzing the variation in the mass flow rate, mass of discharged cuttings, and discharged ratio. The results revealed that increasing the slurry velocity can promote the discharge of cuttings. To keep the discharged rate at a high level, it is recommended that the slurry velocity at the slurry gate should be greater than 0.15 m/s. Reducing the inclination angle of the discharge pipe is conducive to the rapid discharge of cuttings. Cuttings with large diameter or small shape coefficient are more prone to accumulate in the air cushion chamber and cause clogging risk. The research results not only help to improve engineers' understanding of cuttings discharge in slurry shield, but also provide practical guidance for formulating relevant construction measures.