- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

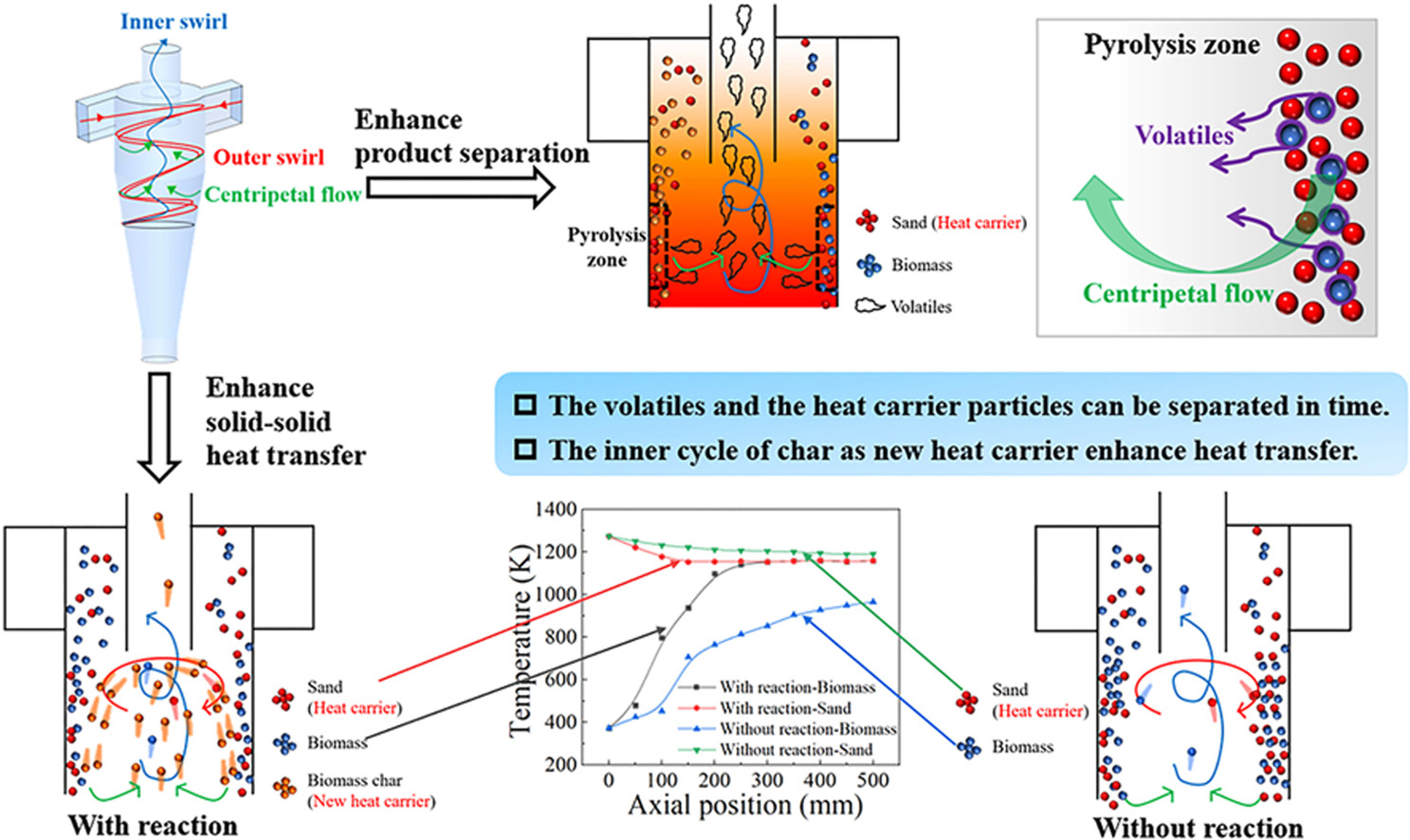

• Effects of gas swirl and pyrolysis on the heat and mass transport are analyzed.

• Heating rate of biomass with pyrolysis is higher than that without reaction.

• Inner cycle of char as new heat carrier with gas swirl enhances heat transfer.

• Pyrolyzed gas products and the heat carrier particles can be separated in time.

Cyclone pyrolyzer is a novel type of downer that combines centrifugal force field and double-layer cyclone vortex. Research on transfer behavior is helpful to optimize the pyrolyzer to meet the needs of pyrolysis. In this study, the Computational Particle Fluid Dynamics (CPFD) model is used to analyze the transfer behavior of binary particles, and finds that the swirl and reaction have a synergistic effect. This effect can increase the heating rate of the particles to the range of flash pyrolysis, and its mechanism lies in the flow field structure of the pyrolyzer. Due to the centrifugal force field, the particles gather to the near wall. The rapid swirl, which facilitates intense gas-solid heat transfer, leads to the rapid heating and pyrolysis of biomass particles. As the pyrolysis proceeds, the mass of the biomass particles becomes smaller and they are more easily affected by the gas flow in pyrolyzer. Under the action of gas flow, char particles serve as new heat carrier to form the inner cycle of particles, which strengthens the heating process. The pyrolysis products are discharged from the exhaust port in time with the flow field of the pyrolyzer to achieve separation from the heat carrier and inhibit the occurrence of secondary reactions.