- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

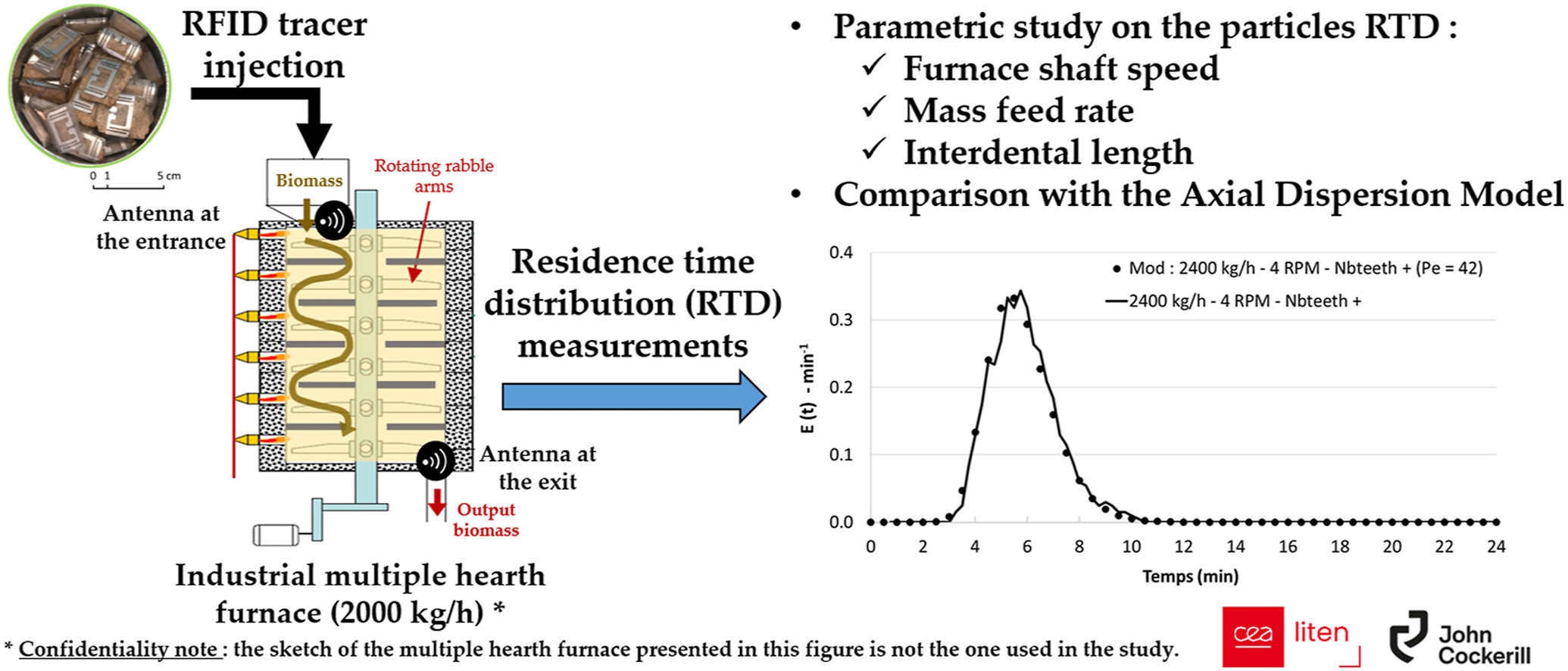

• Residence time distribution of wood chips was carried out in a multiple hearth furnace using RFID tracers.

• Lowering interdental length between two successive teeth increases the biomass bed speed.

• Increase of shaft speed and mass flow rate reduces particles' mean residence time.

• Multiple hearth furnace cannot be considered as an ideal plug flow reactor.

In continuous biomass torrefaction plants, the products' yields, composition and homogeneity highly depend on the residence time of particles. A characterization of particle residence time distribution (RTD) was therefore carried out in an industrial-scale multiple hearth furnace on poplar wood chips using radio frequency identification tracers. The effects of operating conditions, namely, mass flow rate of biomass, shaft speed of the rabbling system and interdental length on the RTD were studied. The increase of shaft speed and mass flow rate reduces particles’ mean residence time. Lowering the length between two successive teeth also increases the bed speed. Uncontrollable biomass accumulation (also called “bulldozing”) was observed during several tests. This phenomenon is favored by a high mass flow rate of resources, a small interdental length between the teeth and a low shaft speed. RTD measurements were compared to the axial dispersion model. For all tests, the Peclet number is ranging between 20 and 62, indicating that the multiple hearth furnace cannot be modelled as an ideal plug flow reactor.