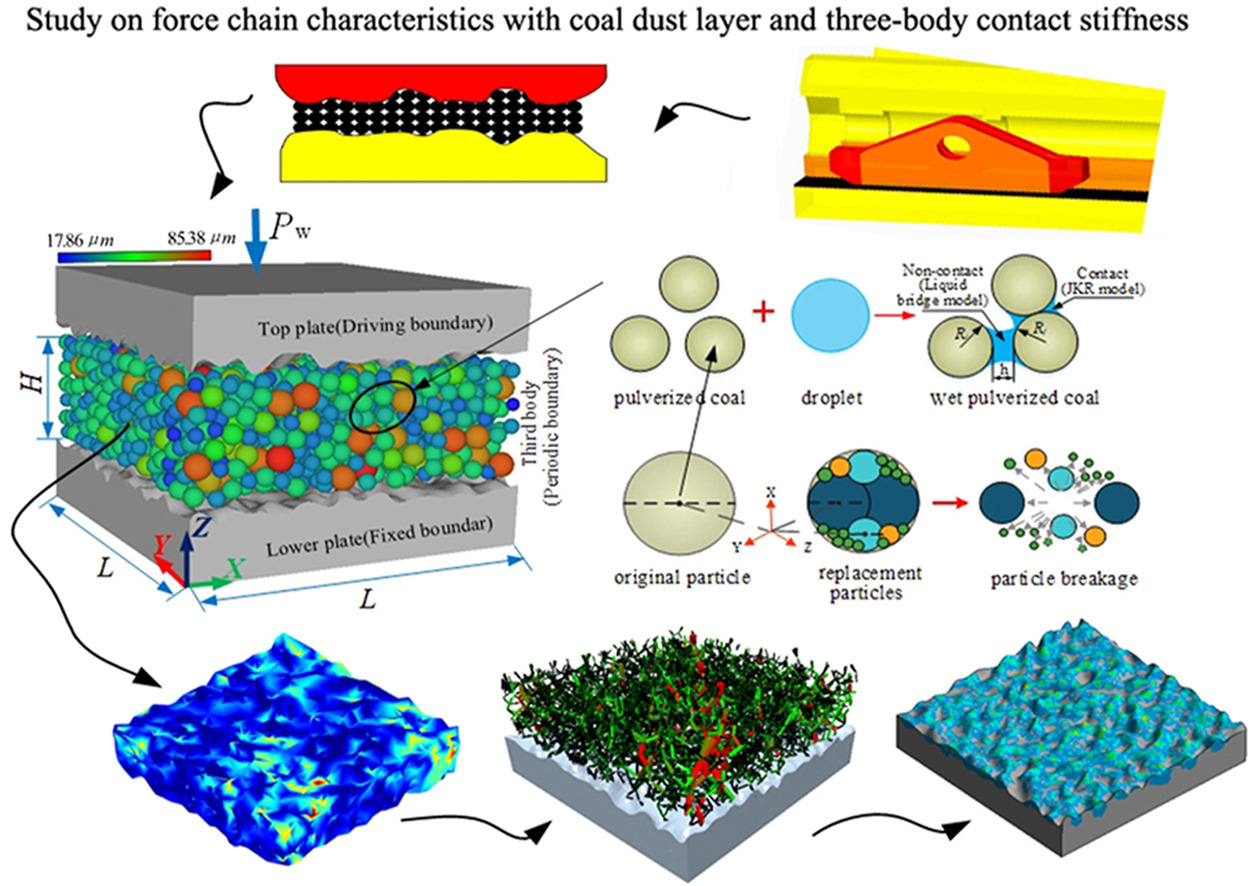

• A three-body contact model was constructed for a humid coal dust-containing interface.

• A secondary development of EDEM software for liquid bridge contact model by python.

• Studied the bearing characteristics of coal dust particle and its force chain configuration evolution.

• Solved the effect of preload force on the contact stiffness of the bonding surface.

To explore the influence of the meso-mechanical behaviors of the wet coal dust layers on the contact stiffness of mechanical bonding surfaces, a three-body contact model incorporating an interface with wet coal dust was constructed based on breakage theory. The model considered the mechanical surface morphology and contact characteristics of the wet coal dust. The force chain evolution laws of the wet coal dust layer were elucidated under the effects of gap filling and the cover layer, and the bearing characteristics of the three-body contact bonding surfaces were revealed by quantitative analyses of the number, length, collimation coefficient, and coordination number of the force chains within the wet coal dust layer. Finally, the three-body normal contact stiffness under various preload forces was computed and experimentally validated. The results demonstrate that the external load transfer path of the three-body contact bonding surfaces was from mechanical surface (macroscopic stress) to wet coal dust layer (mesoscopic force chains) and then to mechanical surface (peaks and valleys). The interactions among these three elements contributed to transforming the distributions of the macroscopic stresses and mesoscopic force chains to the locations at the peaks and valleys of the mechanical surface. Among them, the proportion of short force chains in the wet coal dust layer increased from approximately 0.8%–91%, while the proportion of long force chains exhibited an opposite changing trend. The force chain collimation coefficient initially increased and subsequently stabilized, reaching a maximum value of 0.93. A large number of broken, small particles in the wet coal dust layer mainly served to fill the gaps among large particles. The maximum relative error between the experimental and simulated values on the three-body contact stiffness is 7.26%, indicating that the simulation results can be an approximate substitute for the experimental results with a certain degree of accuracy and practicality. The research results are of great significance for understanding the contact characteristics of mechanical surfaces containing particulate media.