• Flowability and agglomeration behavior of battery grade Li2CO3 were reported.

• Powder flowability was investigated by using the Hausner ratio and the repose angle.

• The optimal doped amount of stearic acid was found to be 0.10 wt% in this study.

• The optimal sample still maintained the excellent flowability even after 5 months.

• The surface free energy was calculated by fitting the Owens-Wendt-Rabel-Kaelble equation.

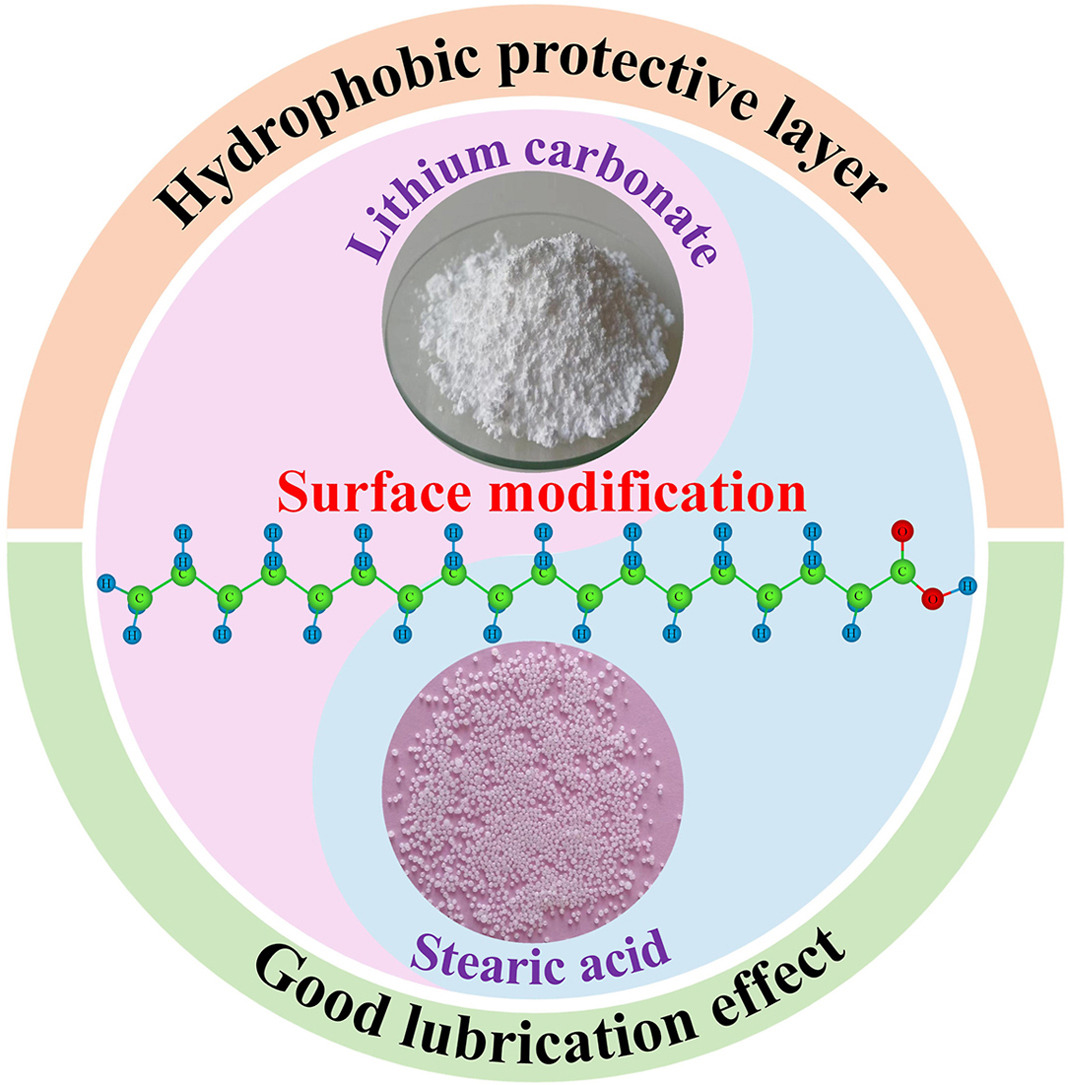

This work investigates the flow and agglomeration behaviors of battery grade Li2CO3 powder and the influence of stearic acid surface modification. The degree of agglomeration is directly related to the uniformity of Li2CO3 and its powder mixtures. According to the Chinese National Nonferrous Metal Industry Standard, battery grade Li2CO3 powder has D50 equal to 3–8 μm which belongs to a micron-sized superfine powder. Therefore, with the extension of storage time, the serious agglomeration phenomenon occurs due to the large specific surface area and rough and irregular powder particles. The Hausner ratio (HR) of the unmodified sample increases from 1.14 to 1.41, and the corresponding flowability is classified as good to poor. Instead, among samples with doping stearic acid, the optimum amount of it is 0.10 wt% which exhibits an extremely stable HR value from 1.14 to 1.16. Meanwhile, after 156 days, the repose angle (AR) obtained for samples without surface modification and using 0.10 wt% stearic acid are calculated to be 49° and 28°, respectively. Based on the values of HR and AR, the flowability of the unmodified sample is poor while the sample modified with 0.10 wt% of stearic acid still maintain excellent powder flow property. Moreover, The LiMn2O4 cathode material synthesized from modified Li2CO3 powder with a stearic acid content of 0.10 wt% exhibits good crystallinity and comparable electrochemical performance to that prepared by commercial Li2CO3. These results indicate that stearic acid has the potential to be an ideal modifier for battery grade Li2CO3 powder that needs to be kept for a long time.