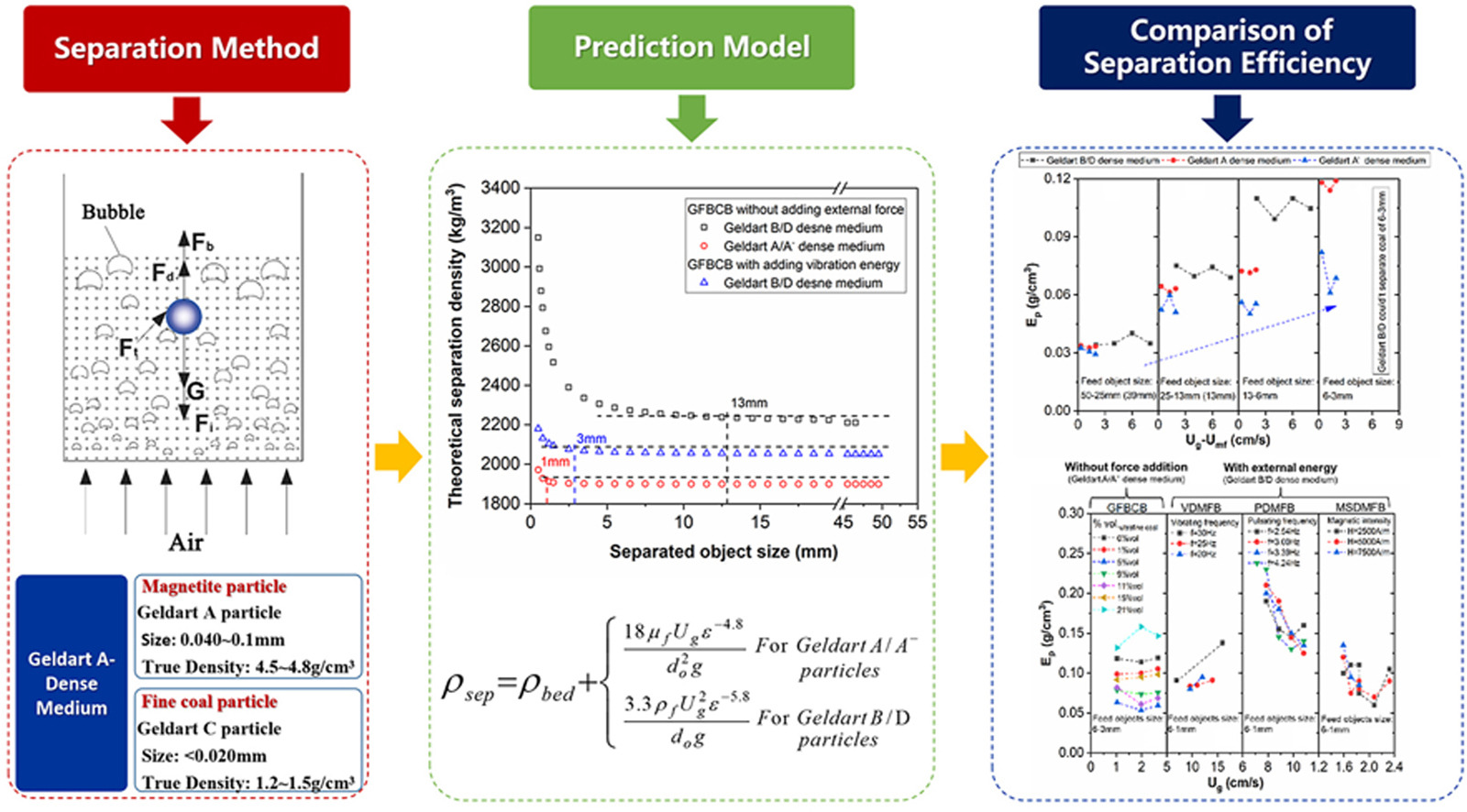

• Geldart A/A– dense medium exhibited better separation performance, with an overall probable error 0.04–0.12 g/cm3.

• A predicted model of separation density based on theoretical derivation was firstly proposed for Geldart A/A– dense medium.

• Geldart A/A– dense medium exhibited better separation performance compared to the traditional Geldart B/D dense medium.

• Geldart A/A– dense medium achieved similar separation accuracy for small objects compared to external energy fluidized bed.

Gas-solid Fluidized Bed Coal Beneficiator (GFBCB) process is a crucial dry coal beneficiation fluidization technology. The work employs the GFBCB process alongside a novel Geldart A– dense medium, consisting of Geldart A magnetite particles and Geldart C ultrafine coal, to separate small-size separated objects in the GFBCB. The effects of various operational conditions, including the volume fraction of ultrafine coal, the gas velocity, the separated objects size, and the separation time, were investigated on the GFBCB's separation performance. The results indicated that the probable error for 6∼3 mm separated objects could be controlled within 0.10 g/cm3. Compared to the traditional Geldart B/D dense medium, the Geldart A/A– dense medium exhibited better size-dependent separation performance with an overall probable error 0.04∼0.12 g/cm3. Moreover, it achieved a similar separation accuracy to the Geldart B/D dense medium fluidized bed with different external energy for the small-size object beneficiation. The work furthermore validated a separation density prediction model based on theoretical derivation, available for both Geldart B/D dense medium and Geldart A/A– dense medium at different operational conditions.