• High-shear granulation is the most used agglomeration processes in the pharmaceutical industry.

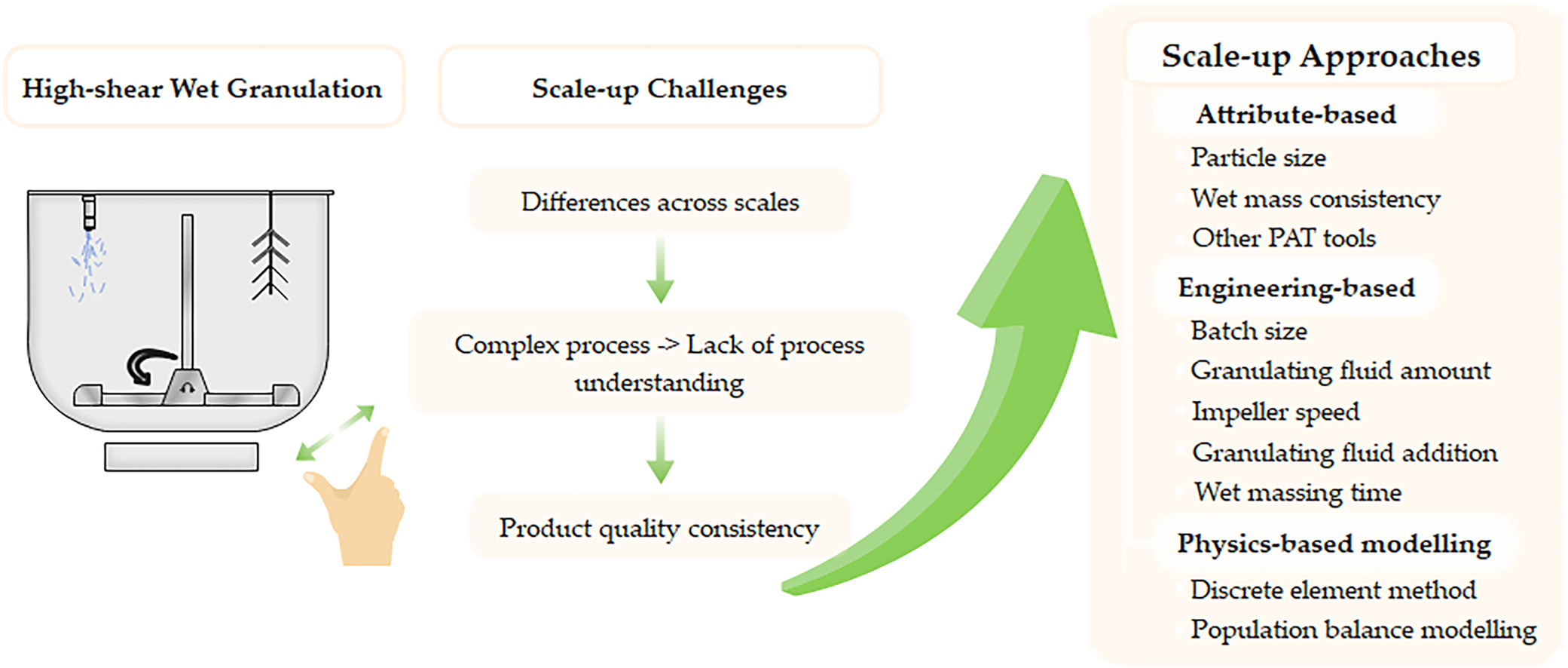

• The scale-up has been divided into two approaches: attribute and engineering-based.

• Recent modelling techniques have gained attention, but a large computational effort is required.

• Despite the available approaches, the scale-up process still needs adaption to product strategy.

Wet granulation is one of the most important agglomeration processes, and high-shear granulation (HSG) one of the most employed technologies in the pharmaceutical industry. The most critical process parameters of HSG are discussed in this work. The main concern in scaling up the wet granulation process is the differences between scales, which prevent the particles from having the same experience across all scales.

The scale-up of wet granulation processes is commonly divided into two categories: engineering and attribute-based methods. An engineering-based scale-up approach is a strategy based on dimensional analysis and an attribute-based supported on the principles of “equifinality”, where process variables are adjusted to obtain equivalent granule attributes. This work presents the effect of different HSG process parameters on the scale-up, as well as the use of process analytical tools (PAT) and modelling strategies. The aim is to review applied scale-up approaches in HSG and discuss benefits and limitations. It is proven why the scale-up for oral solid pharmaceutical products is still considered a hot topic and a very challenging task for development and engineering teams.