Ren, G., Sun, H., Chen, F., Shen, W., Cai, Y., Xu, Y., . . . Xiong, Q. (2024). CFD investigation of structural effects of internal gas intake on powder conveying performance in fuel supply systems for aerospace engines. Particuology, 92, 140-154. https://doi.org/10.1016/j.partic.2024.04.016

CFD investigation of structural effects of internal gas intake on powder conveying performance in fuel supply systems for aerospace engines

Guanlong Ren a b c, Haijun Sun a b *, Fangjun Chen c, Wen Shen a b, Yunzhen Cai a b, Yihua Xu a b, Henrik Ström d, Bilainu Oboirien e, Qingang Xiong c *

a School of Aircraft Engineering, Nanchang Hangkong University, Nanchang, 330063, China

b Engineering Research Center of Aero-engine Technology for General Aviation, Ministry of Education, Nanchang, 330063, China

c State Key Laboratory of Pulp and Paper Engineering, South China University of Technology, Guangzhou, 510640, China

d Department of Mechanics and Maritime Sciences, Chalmers University of Technology, Göteborg, 412 96, Sweden

e Department of Chemical Engineering, University of Johannesburg, Johannesburg, 17011, South Africa

10.1016/j.partic.2024.04.016

Volume 92,

September 2024,

Pages 140-154

Received 5 February 2024, Revised 5 April 2024, Accepted 30 April 2024, Available online 15 May 2024, Version of Record 24 May 2024.

E-mail:

sunhaij1987@163.com; qingangxiong@scut.edu.cn

Highlights

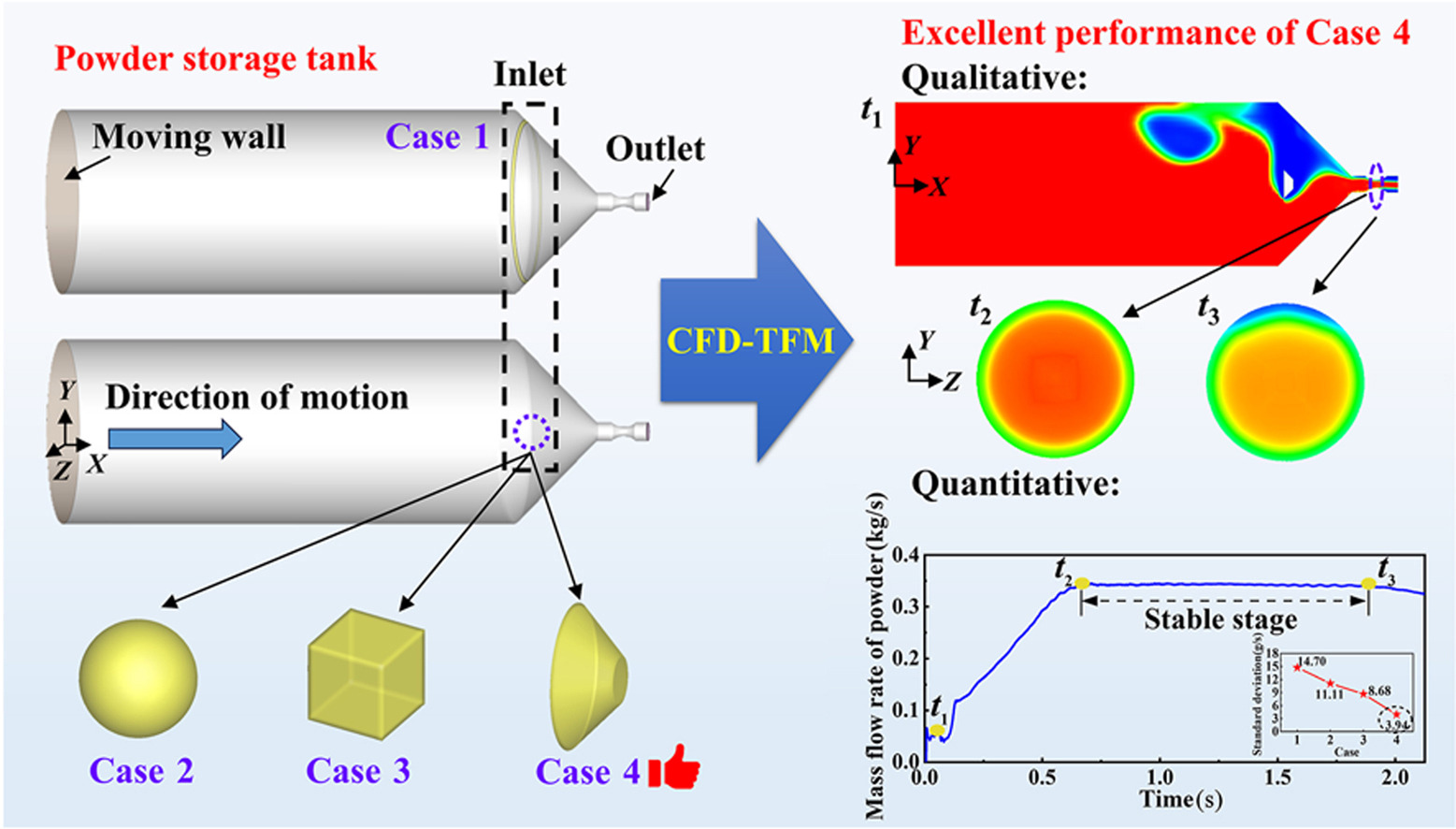

• A novel piston-derived powder supply system with internal gas intake was proposed.

• CFD-TFM coupled with a moving wall was set up for modeling the dense gas-solid flow.

• Performance of internal and external gas intake structures was compared thoroughly.

• Stability of powder conveying at outlet is improved using the dome-shaped structure.

• Dome-shaped internal gas intake shows big potential for powder flow rate regulation.

Abstract

Optimal design of gas intake in powder fuel supply systems is crucial for performance of aerospace engines. There is little research on the impact of intake structure on powder conveying performance. Three novel internal intakes were proposed, which are spherical, cube-shaped, and dome-shaped. After validation, CFD simulations demonstrate that fluctuation of mass flow rate of powders in the dome-shaped intake is reduced by about 73.3% compared with the annular external one. Variation trends of phase velocities are similar for the spherical and cube-shaped intakes, while those are similar for the annular external and dome-shaped internal intakes. Fluctuation of area of gas zone for the annular external and spherical internal intakes is larger than that for the cube-shaped and dome-shaped internal intakes. Pressure and relative pressure drop in the fluidization chamber have a stable stage, and fluctuation of relative pressure drop is small when dome-shaped internal intake is used.

Keywords

Powder supply system; Intake structure; Dense gas-solid flow; Two-fluid model; Powder fluidization; Pressure drop