• Qualitative comparison of standard-based screw conveyors using DEM simulation.

• Numerical study on the applicability and compatibility of three different standards.

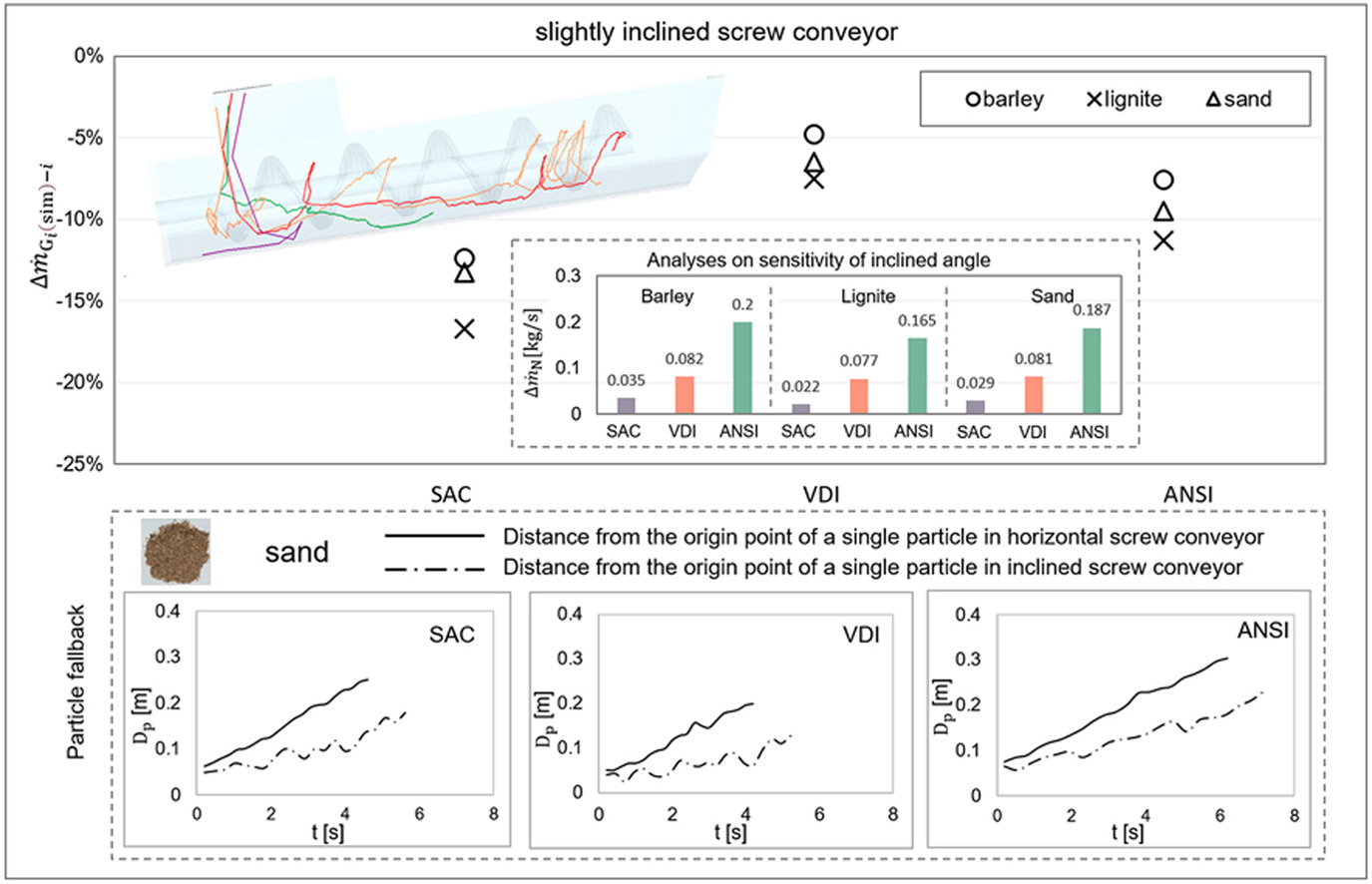

• Overestimated mass flow due to particle fallback is present in all standards.

• Sensitivity analysis to verify the effect of friction coefficients given in the Standardization Administration of China.

• Semi-empirical parameters in the American National Standards Institute lead to notable overestimation of drive power.

This part of the study aims to evaluate the advantages and disadvantages of technical standards of screw conveyors in China, Germany, and the USA for industrial applications. The source or determination method of empirical coefficients as well as the theoretical foundation of dimensioning-relevant diagrams in these standards is not explicitly documented in the literature. Therefore, instead of less efficient on-site tests, the numerical simulation by discrete element method is conducted. Based on the geometrical and operational designs determined in three standards for horizontal, slightly inclined, and vertical conveyance of three representative bulk solids (barley, lignite, and sand), the potential influencing factors are discussed. With constant particle and contact parameters, the potential deviations caused by particle models are eliminated. Furthermore, the accuracy of power consumption calculation of each standard and the divergence between accessible and required mass flows is comprehensively assessed based on the analysis of simulated outcomes. Two main conclusions are drawn: (1) Particle fall back is barely considered by all three standards and leads to overestimated mass throughput; (2) The decrease in mass throughput caused by an increasing degree of filling can be compensated by slowing down the rotational speed.