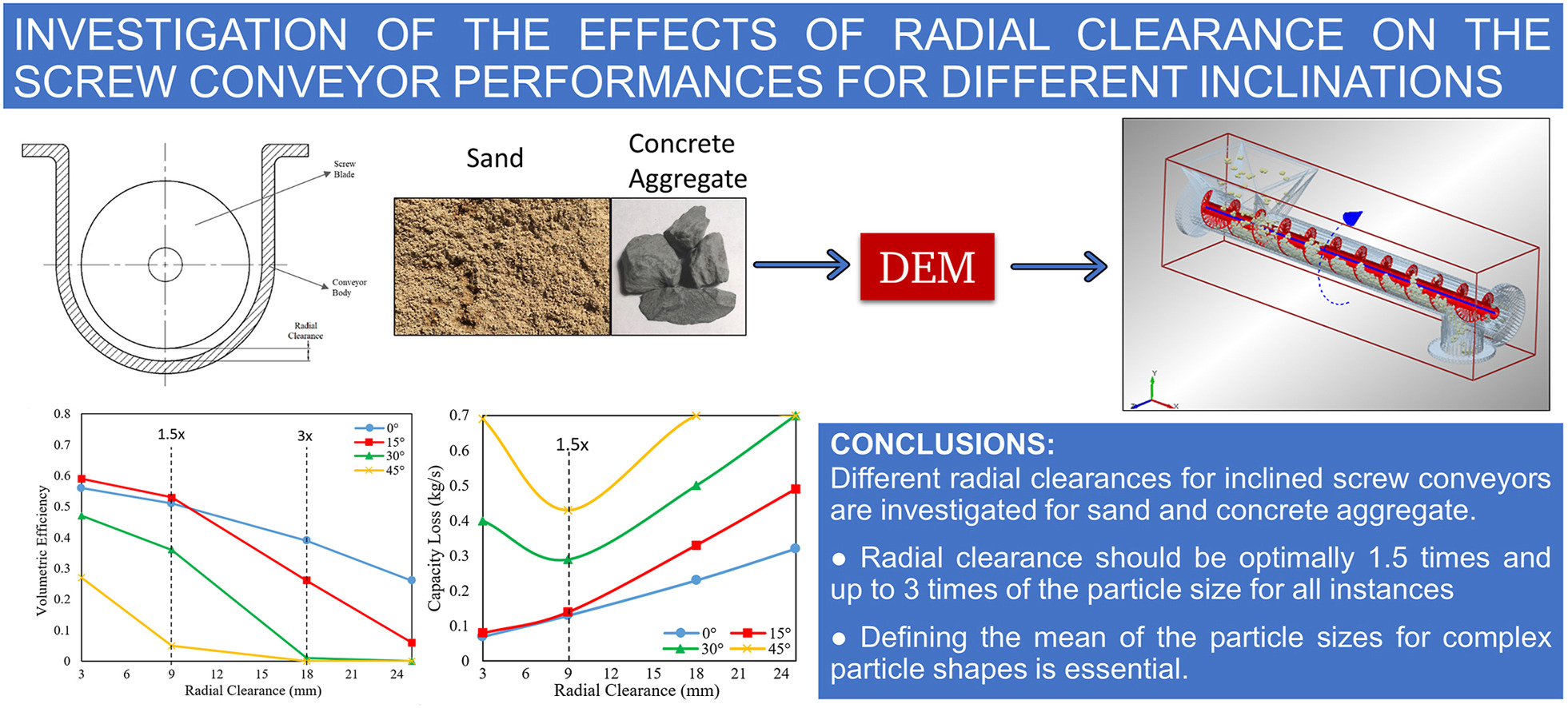

• Different radial clearances for 0°, 15°, 30°, 45° angle screw conveyors are investigated for sand and concrete aggregate.

• Discrete Element Method (DEM) is employed for studying the radial clearance.

• DEM model is validated with the experimental data.

• Radial clearance should be optimally 1.5 to 3 times of the particle size for different inclinations and particle shapes.

• Considering the mean value of the particle dimensions is essential as the particle interacts with the clearance randomly.

Screw conveyors are widely used for bulk material transportation. This study investigates the critical role of radial clearance, the gap between the screw and the conveyor body, on performance across various inclination angles. The Discrete Element Method (DEM) is employed to analyze the effects of different radial clearances on conveyor performance for concrete aggregate and sand as bulk materials. Volumetric efficiencies and capacity losses serve as key performance indicators, quantitatively assessed for each radial clearance and inclination combination. Experimental validation is conducted to corroborate the findings. In the study, the optimal radial clearance was identified as 1.5 to 3 times of the particle size. This optimal clearance minimizes the material jamming and increases the performance for screw conveyors with different inclinations and bulk material types as a result.