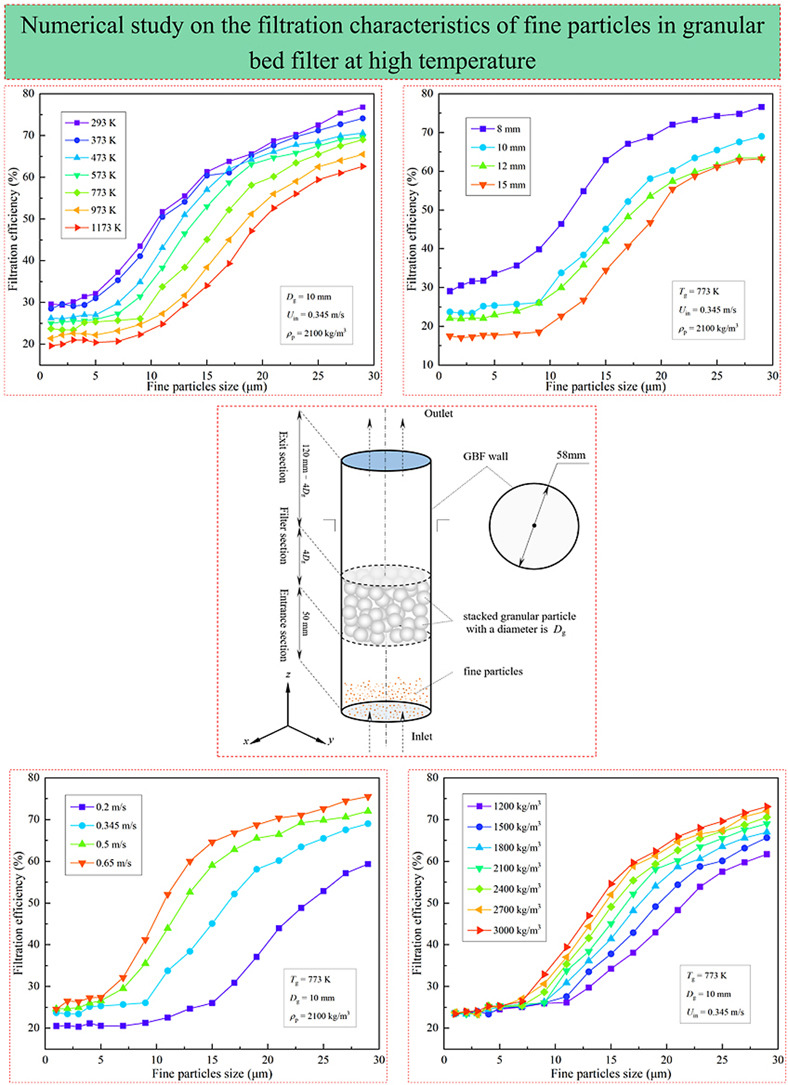

• A 3D filtration model for granular bed filter was established and validated.

• Increasing the temperature and inter gas velocity will improve filtration efficiency.

• As The diameter of stacked granular particles grows, filtration efficiency drops.

• For fine particles of 1∼7 μm, their density has no effect on filtration efficiency.

• Fine particles have first and second critical particle size.

Granular bed filter (GBF) has become one of the current research hot topics due to its excellent performance in removing fine particles. In this paper, a three-dimensional fixed bed GBF filtration model was established and its accuracy was verified. Then, the GBF filtration performance at high temperature were studied. The results demonstrate that elevating the temperature diminishes the filtration efficiency, albeit to a limited extent. The increasing of inlet gas velocity can significantly improve pressure drop for GBF and the filtration efficiency for fine particles of sizes larger than 5 μm. As the diameter of stacked granular particle diameter grows, the filtration efficiency and pressure drop drops. The density of fine particles almost does not affect the filtration efficiency for fine particles of 1∼7 μm, but a higher density leads to a higher filtration efficiency for fine particles of sizes bigger than 9 μm. Additionally, as the fine particles size increases, the change of the filtration efficiency roughly goes through three stages: Stage 1: the filtration efficiency is basically unchanged; Stage 2: the filtration efficiency increases rapidly; Stage 3: the filtration efficiency increases steadily, but the rate of increase slows down. With the increase of the fine particles Stokes number, the filtration efficiency of GBF will pass through two phases of stabilization and rapid increase.