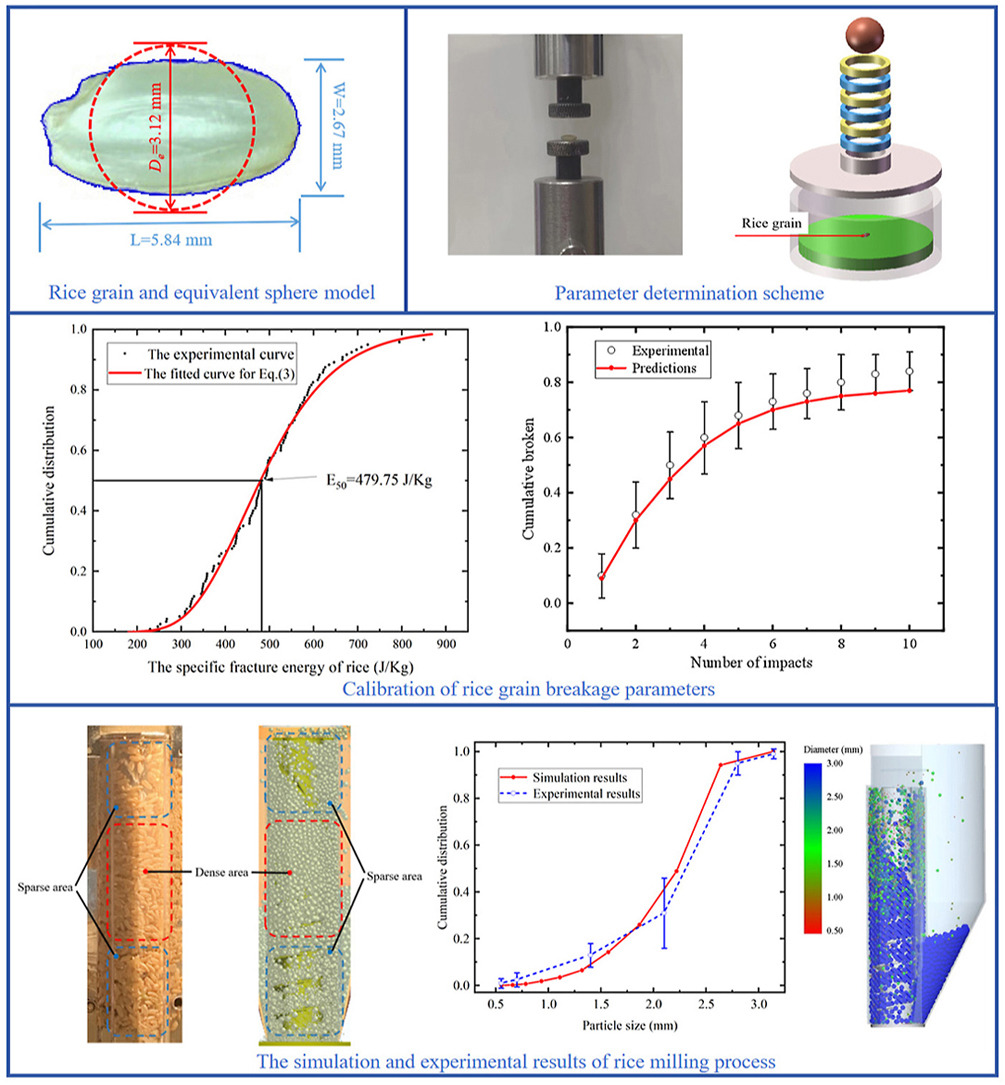

• A new breakage model of rice grain was constructed based on discrete element method.

• The breakage model parameters of rice grains were determined.

• The breakage process of rice grains was simulated in vertical circulation rice mill.

• The location of broken rice inside the mill was identified.

Understanding the breakage characteristics of rice grains is an important means to reduce rice breakage rate. However, the dynamic breakage mechanism of rice grain is unclear due to the lack of a reasonable breakage model. In this study, the uniaxial compression test and drop weight test of single rice were carried out, the breakage model of rice grain was constructed, the reliability of rice model was verified by the experiment and simulation results. The results showed that the fracture energy distribution of rice can be obtained by uniaxial compression test, the specific fracture energy of rice accords with a lognormal distribution, and the median specific fracture energy of rice is 479.75 J/kg. The damage accumulation coefficient and fragment size distribution of rice can be acquired by drop test, the result of damage accumulation coefficient of rice was 4.3. Rice grain breakage mainly occurs in the milling section of the vertical circulation rice mill.