• Adjusting the pulverized coal injection angle significantly improves combustion efficiency.

• Different blowing methods affect temperature distribution and gas flow in the furnace.

• Optimizing injection parameters enhances fuel utilization and reduces emissions.

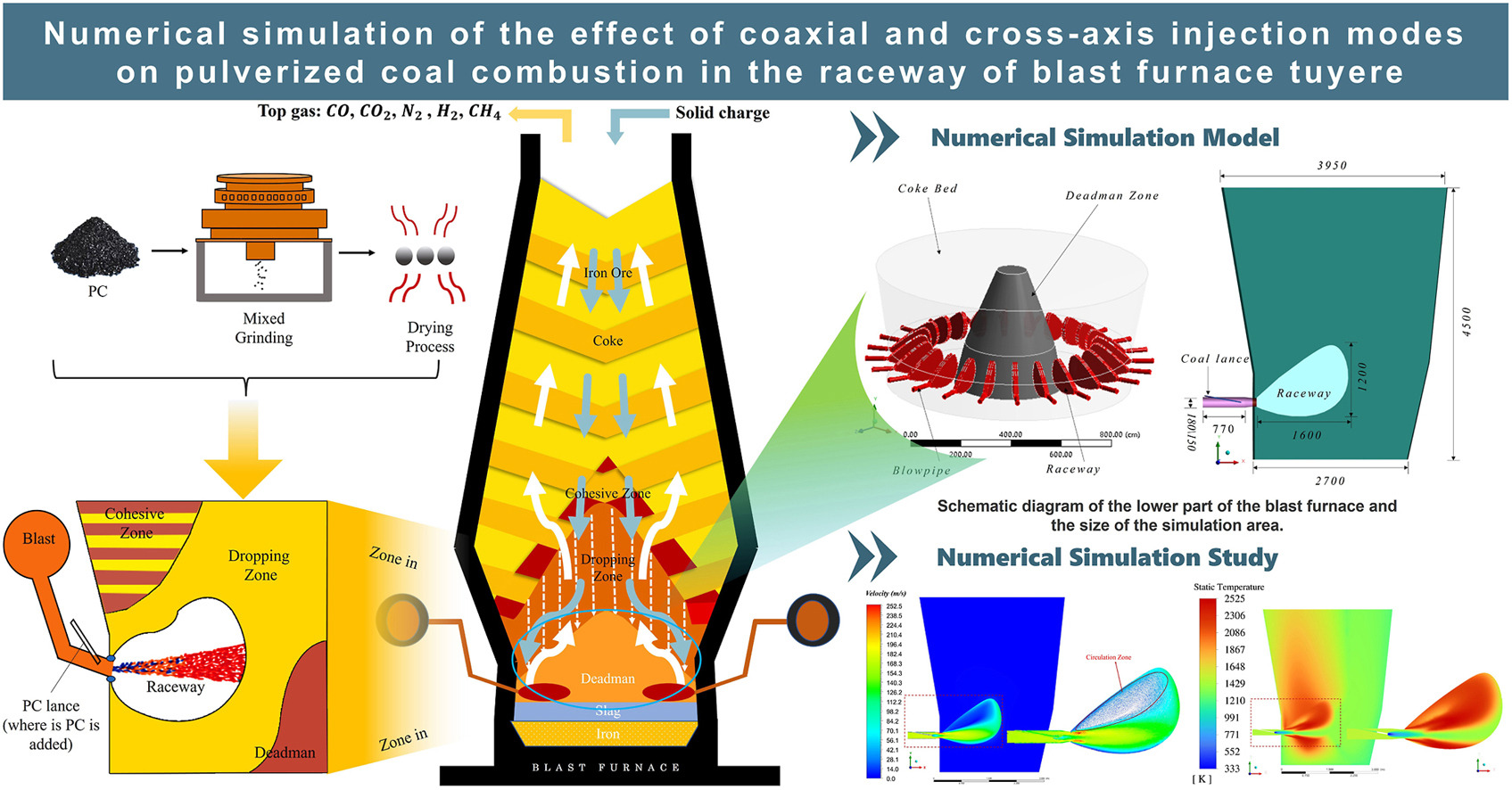

The aim of this study is to investigate the influence of the angle of the pulverized coal (PC) injection lance on the combustion characteristics of fuel in the raceway of blast furnace tuyeres. Using FLUENT software, a Euler-Lagrange three-dimensional numerical model was constructed to analyze the influence of different positions of blast furnace tuyere coal powder injection lance (coaxial and cross-axis) on key parameters such as temperature distribution, gas flow, and combustion efficiency. The results demonstrate that adjusting the angle of the injection lance significantly modifies the average and peak temperatures in the raceway, while the composition of gas components remains relatively stable. When the injection lance angle is 10°, the average temperature and peak temperature in the raceway are 2294 K and 2747 K, respectively. When the injection lance angle is 12°, the combustion efficiency of the PC reaches 80.8%. This study reveals the significant impact of the injection lance angle on the combustion process. Especially at an angle of 12°, the combustion efficiency of the blast furnace significantly improves. With coaxial injection, the combustion rate increases as the distance between the injection lance tip and the tuyere increases. This paper is instructive for the optimization of the blast furnace combustion system, which improve fuel utilization efficiency and reduce environmental emissions. This paper provides practical recommendations for adjusting blast furnace operational parameters, offering insights for achieving more efficient and environmentally friendly industrial production.