• A DEM-MBD coupling simulation model of screen-cleaning device was established.

• Mathematical models between excitation force and factors were established.

• Collision mechanism of elastic ball particles was clarified.

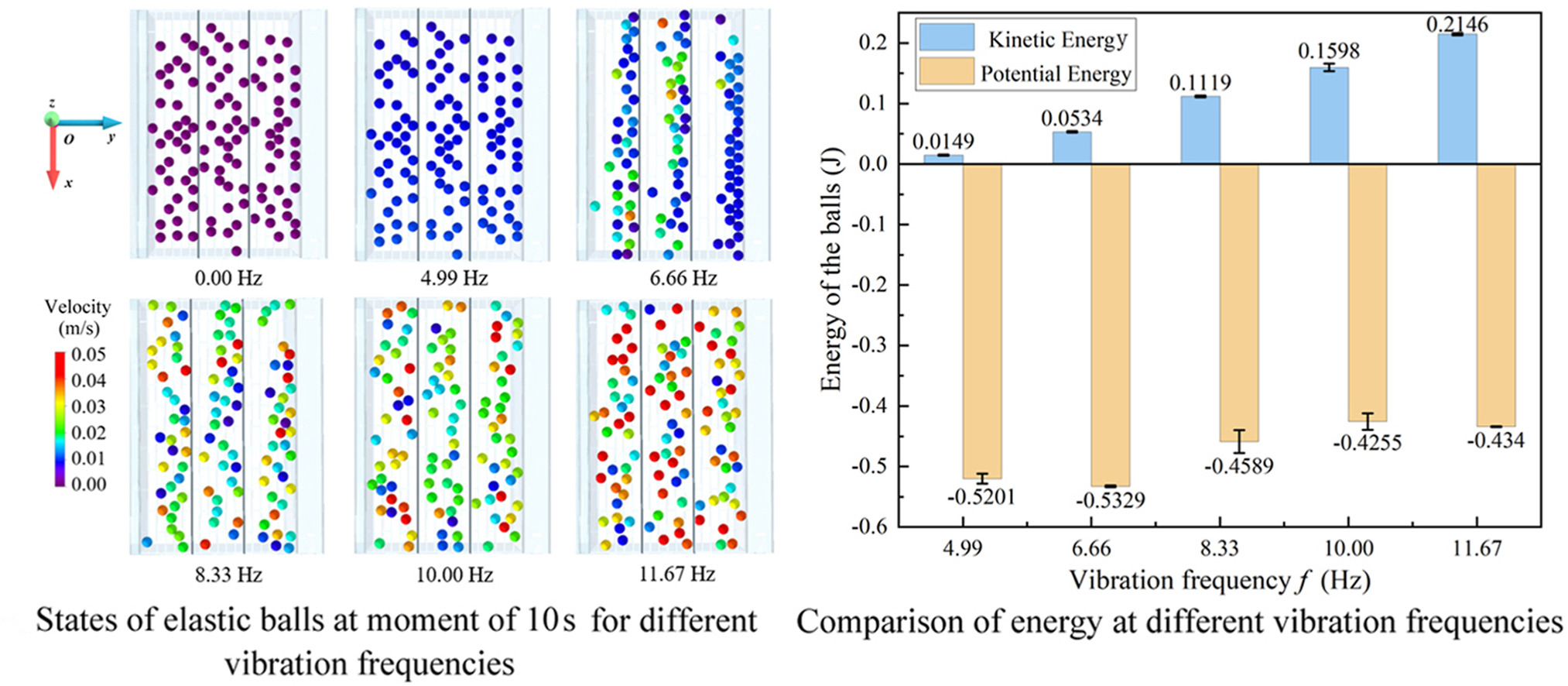

• Motion law of elastic balls under different vibration frequencies was studied.

• Self-purification rate can be improved through variable frequency screen-cleaning.

In seed breeding, the vibrating screen used for pre-sowing grading parental seeds often has the problem of poor self-purification rate. Using elastic balls to clean the plugging seeds and ensure the self-purification of the screen is a viable technical solution. To clarify and improve the operating performance of the elastic ball particles, a DEM-MBD coupling simulation model of the elastic ball screen-cleaning device was established in this study, and a numerical simulation analysis of the complex motion process was carried out. The mechanism of action of the elastic ball was explained more completely from the aspects of excitation force and energy transfer. Through the Plackett-Burman test, it was determined that the vibration frequency has the most significant effect on the excitation force. Multiple linear regression analysis was performed on each factor and the mathematical relationship equation. It was found that when the maximum excitation force was greater than 7 N and the average excitation force was greater than 2 N, the self-purification rate was greater than 95%. The self-purification rate was then increased to 99.81% by variable frequency tests. The variable frequency achieved better self-purification effect.