-

Volumes 84-95 (2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 94

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

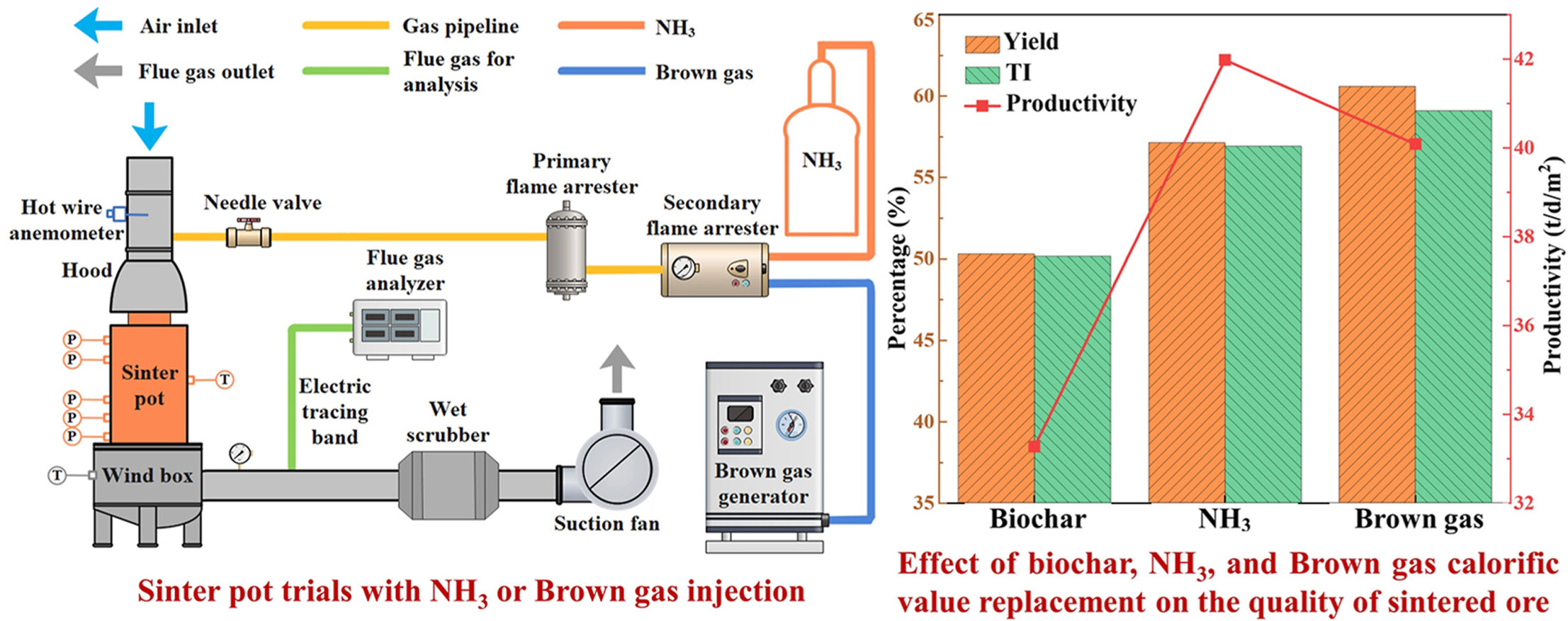

• Heating and cooling rates during the sintering process were calculated.

• Effects of Brown gas and ammonia on sintering bed's temperature were studied.

• Effects of Brown gas and ammonia on sintered ore's quality were investigated.

• Effects of two gases replacing biochar on sintering characteristics were explored.

• A low-carbon sintering method using biochar swap and gas injection was obtained.

The influence of ammonia and Brown gas injection on the iron ore sintering characteristics was explored through sintering pot experiments based on biochar substitution to increase biochar substitution proportion and reduce fossil energy consumption. By dividing the high-temperature stage of the sintering bed, the heating rate and cooling rate were calculated, and the reasons for poor sintering quality under a high biochar substitution ratio were explored. The results showed that under the 40% biochar substitution ratio, the cooling rate of the sintering bed significantly increased, the high-temperature duration time was short, and the sintering quality deteriorated severely. Additional injection of 0.5–1% vol ammonia or 1–2% vol Brown gas can reduce the cooling rate, prolong the high-temperature duration, and optimize the sintering quality. Based on 1% vol ammonia or 2% vol Brown gas injection, reducing the proportion of biochar with equal calorific value further increases the sintering comprehensive index, which means that using 1% vol ammonia or 2% vol Brown gas injection to assist sintering can reduce the proportion of coke usage to 60%, while the proportion of biochar substitution is 33.76% and 32.47%, respectively. The research results provide an effective solution for low-carbon sintering.