-

Volumes 84-95 (2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 94

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

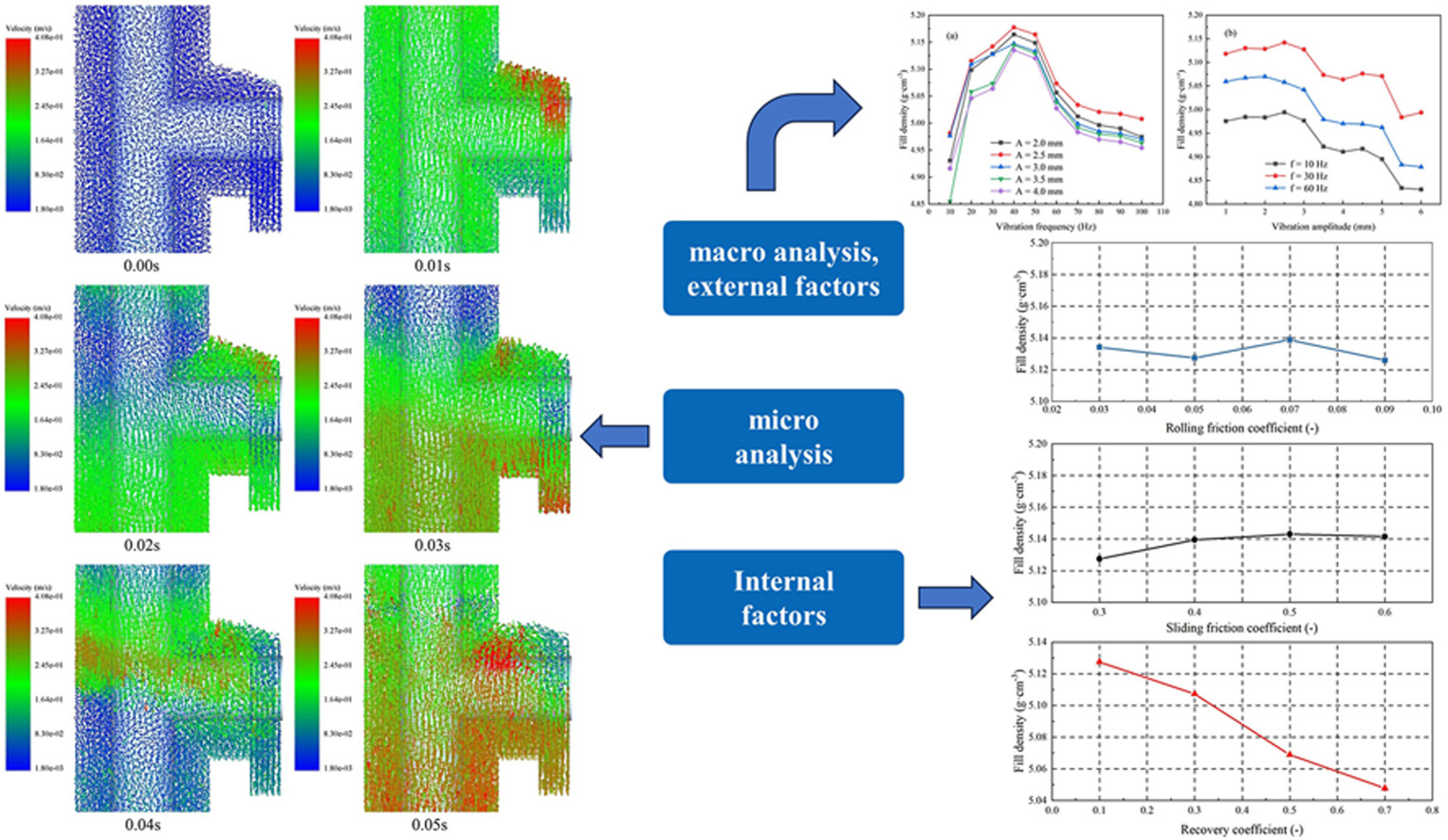

• Determine the optimal process parameters from the perspective of particle mechanics.

• In vibration, particles come into contact in the form of high-frequency collisions.

• Explored the mechanism of vibration densification from macro and micro perspectives.

• Splitting a single harmonic vibration to characterize the velocity field.

• Use coordination number to reflect the filling state of metal powder in capsules.

In this study, the discrete element method was combined with physical experiments to examine the capsule filling practice in the hot-isostatic-pressing process and to study the densification of spherical particles in a three-way pipe capsule for offshore engineering under mechanical vibration conditions. The effects of vibration parameters—such as the vibration time, vibration frequency, vibration amplitude, rolling friction coefficient, sliding friction coefficient, recovery coefficient, and other particle properties—on the filling density were analyzed. The results showed that the packing density in the three-way capsule could be increased considerably using a vibration frequency of 40 Hz and a vibration amplitude of 2.5 mm. The contact form between particles in the vibration-assisted mold-filling process was determined and the particle velocity field, compression force, and coordination number under a single harmonic vibration period were analyzed. The real-time motion of the particles at the micro level was visualized, and the mechanism of the mechanical vibration effect on mold filling and densification was explored. The distribution and evolution of the coordination number indicated that the distribution of the filling density was uneven, and that the change in the coordination number of particles at the bottom exhibited no major response to the vibration.