-

Volumes 84-95 (2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 94

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

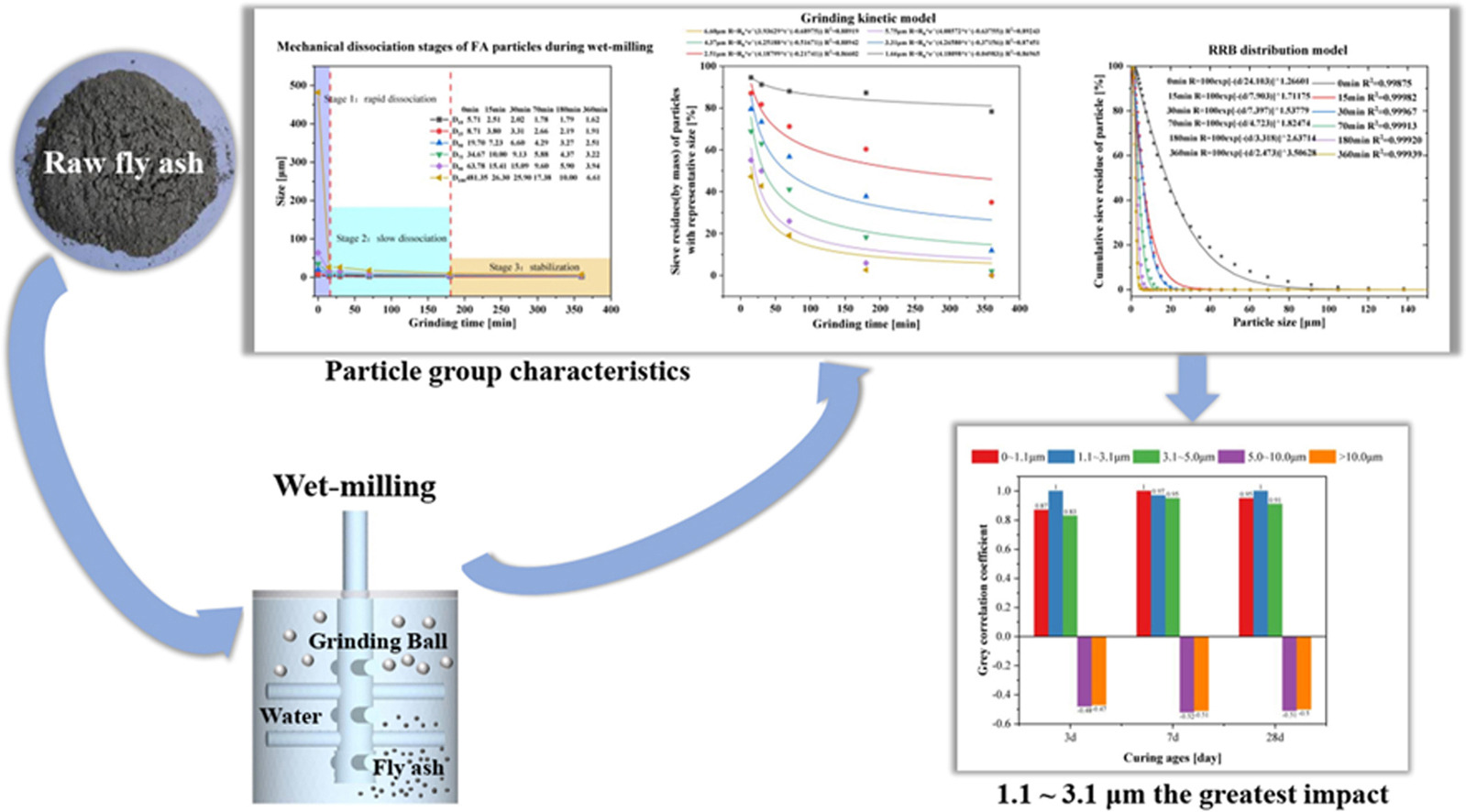

• A wet-milling kinetics of fly ash is studied.

• Wet-milling process of fly ash follows well with Divas-Aliavden equation.

• Evolution process of PSD is consistent with the Rosin-Rammler-Bennet distribution.

• Influence of particle characteristic parameters on activity index are analyzed.

• Effect of different particle sizes and characteristic particle size on activity index are conducted.

Wet-milling in liquid-solid system can achieve ultra-fine mechanical dissociation of solid wastes with low energy consumption, thereby efficiently improving the potential pozzolanic reactivity. However, the wet-milling kinetics of ultrafine dissociation in liquid-solid system has not been fully investigated. This paper systematically investigates the wet-milling kinetics of fly ash (FA). Results showed that before wet-milling of FA for 360 min, no agglomeration effect was observed. The particle dissociation of FA during wet-milling can be divided into three stages: rapid dissociation, slow dissociation and stabilization. The evolution process of particle size distribution during wet-milling is consistent with the Rosin-Rammler-Bennet distribution. Both the particle uniformity coefficient and fractal dimension showed highly positive linear correlation with the strength activity index of wet-milled FA. The grey correlation analysis showed that FA particles between 1.1 and 3.1 μm had the greatest impact on both the early and late strength activity index. Simultaneously, D10 of wet-milled FA has the largest impact on strength activity index at each age, while D100 has the least impact. Therefore, D10 and proportion of particles in 1.1–3.1 μm can be an important basis for judging the reactivity of wet-milled FA as ultrafine supplementary cementitious materials.