-

Volumes 84-95 (2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 94

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

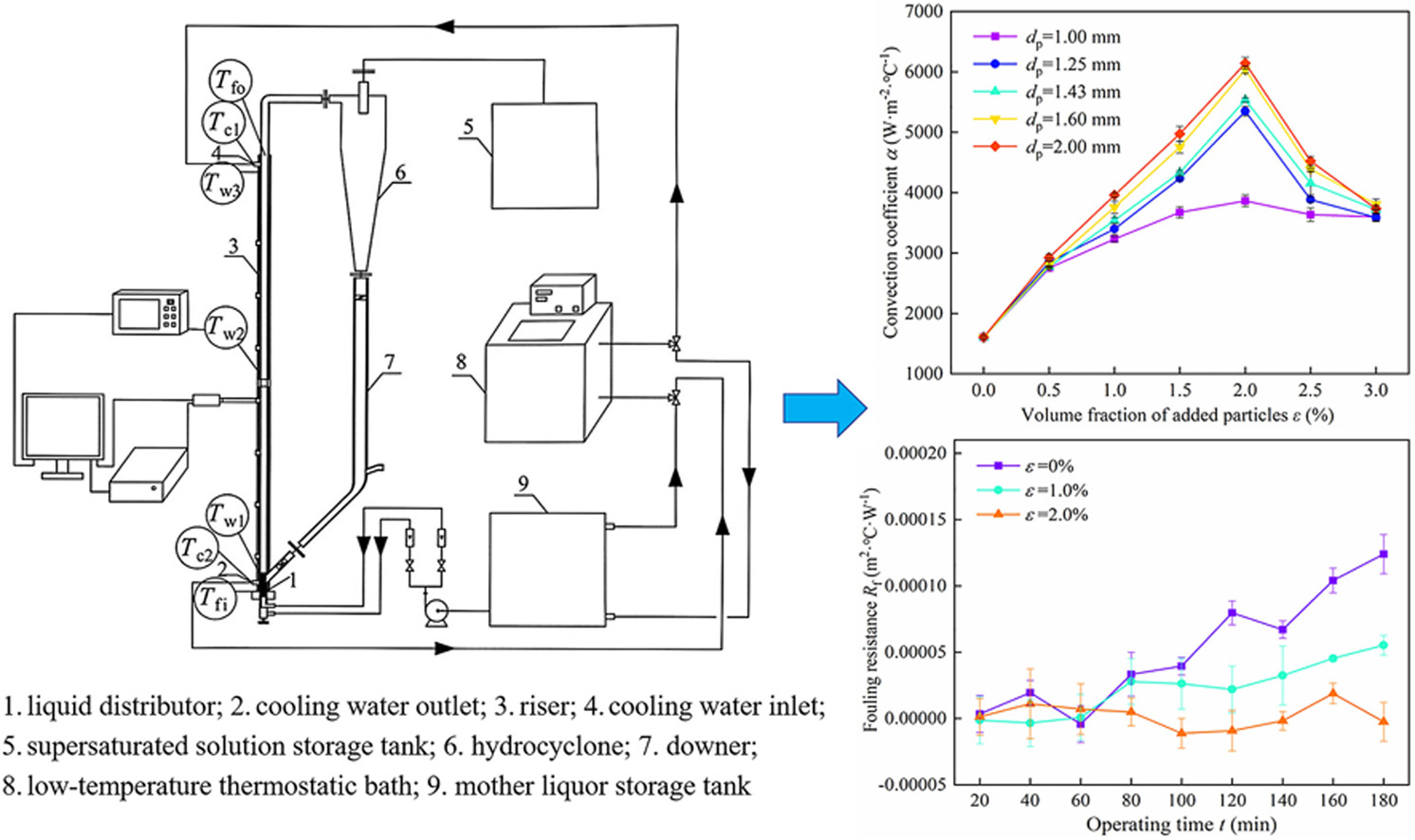

• Multiphase flow technology is firstly applied to anti-fouling of external cooler.

• A double-tube cooler with liquid-solid fluidization operation is developed.

• Heat transfer and anti-fouling performance are enhanced after adding particles.

A double-tube cooler with liquid-solid circulating fluidization operation and corresponding parameter measuring system are developed to avoid fouling of inner walls of heat exchange tubes in a cryogenic temperature external cooler of ammonium chloride solution in soda ash production. Wall-scaling prevention performance of the cooling process is experimentally evaluated using convection and overall coefficients, enhancement factor, wall temperature and fouling resistance. Effects of different volume fractions of added particles, particle size, superficial liquid velocity, and cooling medium temperature on heat transfer are examined. Under present conditions, convection coefficient of liquid-solid flow inside the tube of external cooler is higher than that of the liquid phase flow, increased by 0.7–2.8 times, enhancing cooling performance obviously. Convection coefficient initially increases and then decreases as the volume fraction of added particles increases, reaching its maximum value at a volume fraction of 2.0%. The wall-scaling prevention effect of glass beads mainly depends on the volume fraction of added particles; optimal anti-fouling effects are achieved when adding particles at a volume fraction of 2.0%, regardless of changes in superficial liquid velocity or cooling medium temperature. This study lays a foundation for industrial applications of this new technique of fluidized bed external coolers.