-

Volumes 84-95 (2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 94

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

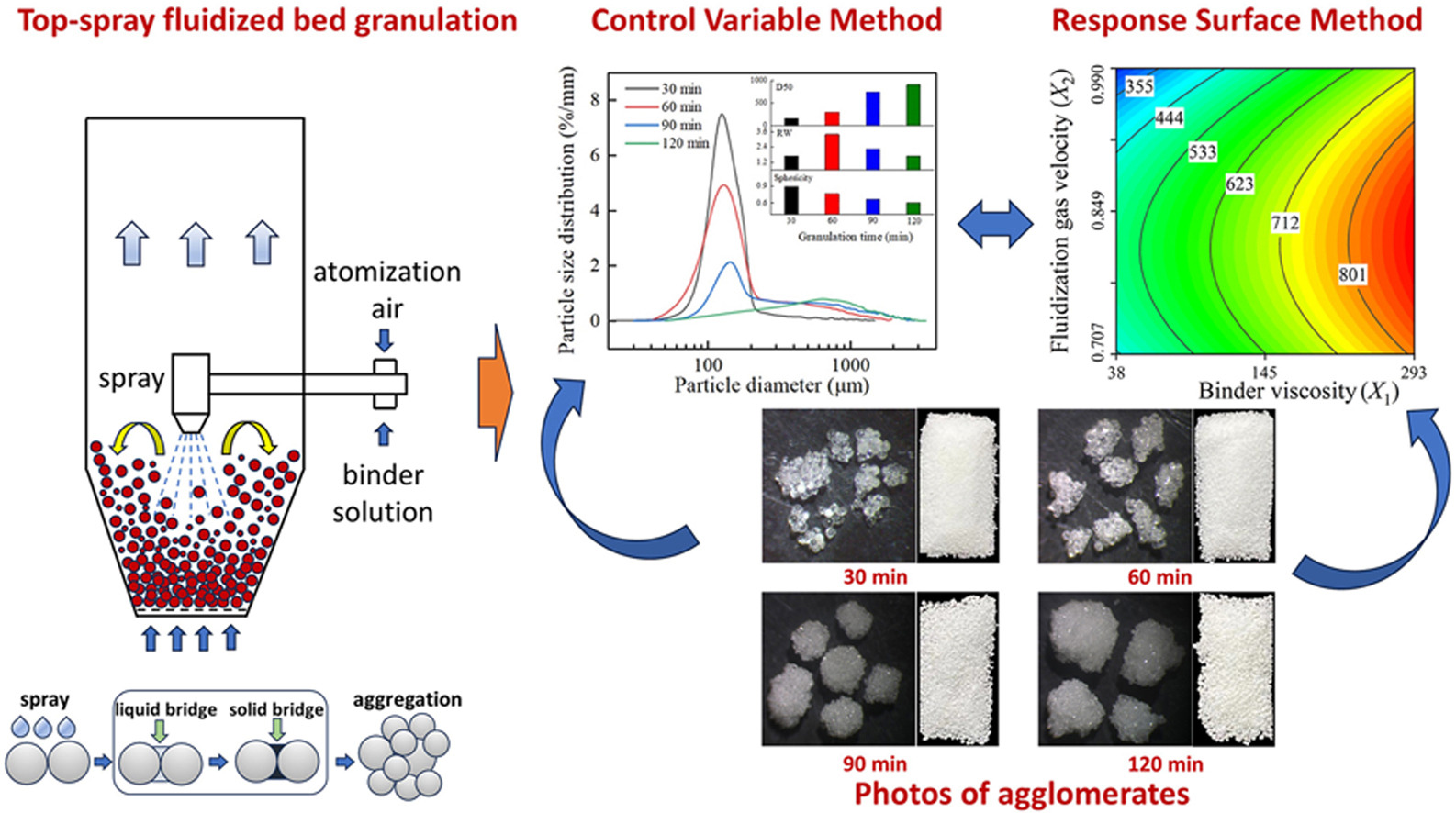

• Agglomeration process in a top-spray fluidized bed was studied.

• Response Surface Methodology was employed to reveal the multi-factor interactions.

• Effects of various operating parameters on agglomerate properties were examined.

• Mean particle size, particle size distribution, and sphericity were measured.

Considering the strong dependence of agglomerate characteristics on various operating parameters, this study employs the control variable methodology (CVM) and response surface methodology (RSM) to investigate the influence of multi-factor interactions on particle growth during top-spray fluidized bed agglomeration. First, CVM is conducted to assess the effects of individual operating parameters on the agglomerate properties, such as mean particle size, relative width, and sphericity. Then, the interactive relationship between these input variables and the quality attributes of the process is investigated using RSM. The results show that the mean particle size increases with the increase of binder viscosity and spray rate, while it decreases with the increase of fluidization gas velocity and inlet gas temperature. The relative width of the particle size distribution increases with the spray rate, binder viscosity, and fluidization gas velocity, and hardly changes with the inlet gas temperature. The mean particle size is more sensitive to the binder spray rate at a lower level of fluidization gas velocity or a higher level of inlet gas temperature. The fluidization gas velocity corresponding to the maximum D50 changes when the binder viscosity and binder spray rate are at different levels.