-

Volumes 84-95 (2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 94

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

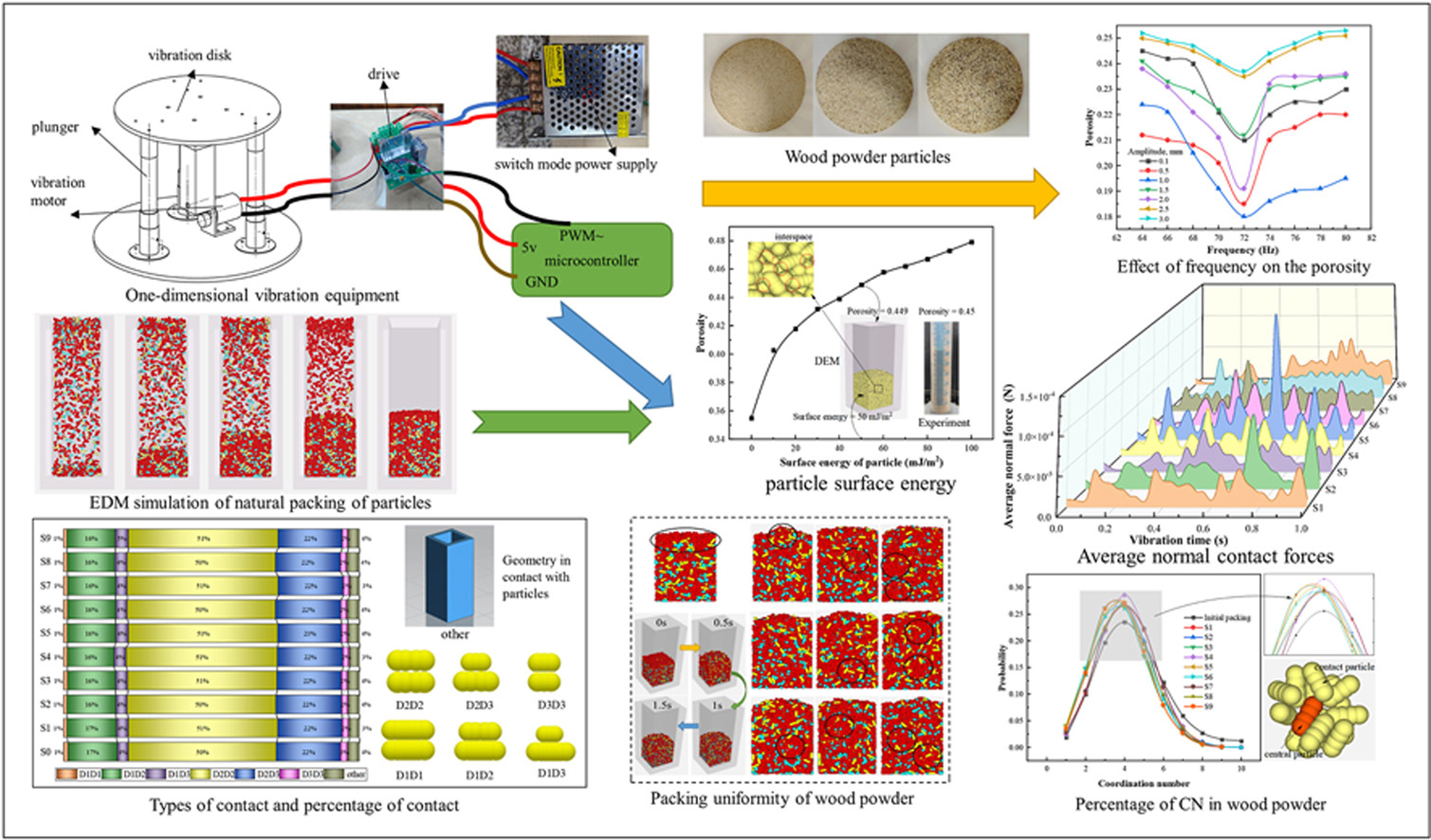

• Experimental study of porosity changes in wood powder particle stacking structures under one-dimensional vibration.

• Experimental results are combined with numerical simulations to obtain surface energy parameters of wood powder particles.

• Analyzing microscopic properties of the stacking structure of wood powder particles under different vibration conditions.

• Combining experimental and dynamic simulation analysis to obtain optimal vibration conditions.

In the industry of production of high-density fiberboards without adhesive, applying vibration to the particle packing system before pressing and molding is an effective way to improve the uniformity of particle packing and reduce porosity. In this work, physical experiments combined with numerical simulations are used to systematically investigate the packing structure behavior of wood powder particles under different vibration conditions. Macroscopic and microscopic properties such as porosity, coordination number, radial distribution function, and contacts are characterized and analyzed. The results indicate that when the vibration frequency is 72 Hz and the vibration amplitude is 1 mm, the porosity of wood powder particles closely packed is minimized. The results of the Discrete Element Method show that the distribution of the coordination number is approximately normal. As the vibration conditions change, the packing structure becomes tighter, but the main peak of the radial distribution function becomes blurred or even disappears. Vibration does not significantly change the type of contact in the packing structure. The conclusions can provide more comprehensive vibration conditions and microscopic theories for the uniform spreading of wood powder particles before pressing, ensuring that the finished panels have excellent mechanical and physical properties.