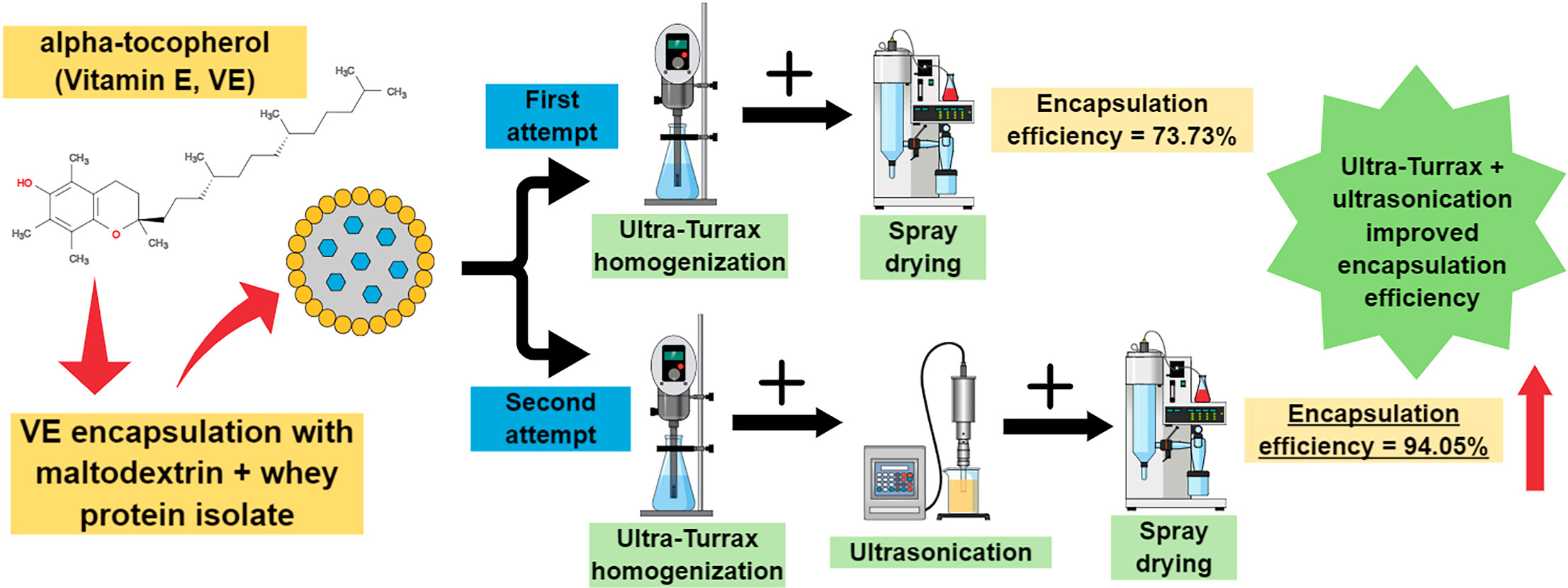

• Vitamin E was firstly encapsulated using Ultra-Turrax homogenization/spray drying.

• Use of ultrasonication in an additional homogenization step was then evaluated.

• The best spray drying conditions were drying air temp. as 180 °C and feed flow rate as 0.6 L/h.

• Encapsulation efficiency was 73.73% in the first stage (Ultra-Turrax/spray drying).

• Ultrasonication enabled the encapsulation efficiency to be increased to 94.05%.

Vitamin E, a soluble antioxidant widely used in the food and pharmaceutical industries, is rich in tocopherols and phytosterols. Since vitamin E molecules are highly sensitive to oxidation, encapsulation is a viable and effective technique for preservation of the properties of Vitamin E and improving its stability during storage, maintaining the nutritional value. In this work, the aim was to encapsulate concentrated vitamin E using a combination of Ultra-Turrax and ultrasonication to achieve higher encapsulation efficiency in spray drying. In the first stage, the vitamin E oil was encapsulated employing only Ultra-Turrax homogenization, with subsequent optimization of spray drying. The coating materials used were maltodextrin and whey protein isolate. Optimization of the spray drying step evaluated the effects of the drying air temperature (T) and the feed flow rate (Q), to obtain better yields and a high-quality product. In the second stage, the use of ultrasonication in an additional homogenization step was evaluated, aiming to further improve the encapsulation process. The results showed that the best drying conditions (first stage) were T = 180 °C and Q = 0.6 L/h, which provided the highest yield (67.73%) and high encapsulation efficiency (73.73%). The microspheres produced had similar properties, with mean diameters ranging from 0.64 to 12.99 μm. In the second stage of the investigation, the application of ultrasonication immediately after the Ultra-Turrax homogenization enabled the encapsulation efficiency to be increased to 94.05%, with a yield of 57.54%, using an ultrasonication time of only 7 min. This showed that addition of the ultrasonic homogenization step to the process greatly improved the encapsulation efficiency and could be used to produce vitamin E-enriched powder microcapsules by spray drying, with application in the food industry.