• Li2MnO3 coating and Ta5+ doping are adopted to improve the LiNi0.90Co0.05Mn0.05O2.

• Li2MnO3 covering could afford the extra lithium and restrain the side reaction.

• Ta5+ doping restricts the release of high activity oxygen species from cathode.

• High structure and morphology stability are obtained by Li2MnO3 coating and Ta5+ doping.

• Ta5+ doped LiNi0.90Co0.05Mn0.05O2@Li2MnO3 demonstrates the excellent electrochemical properties.

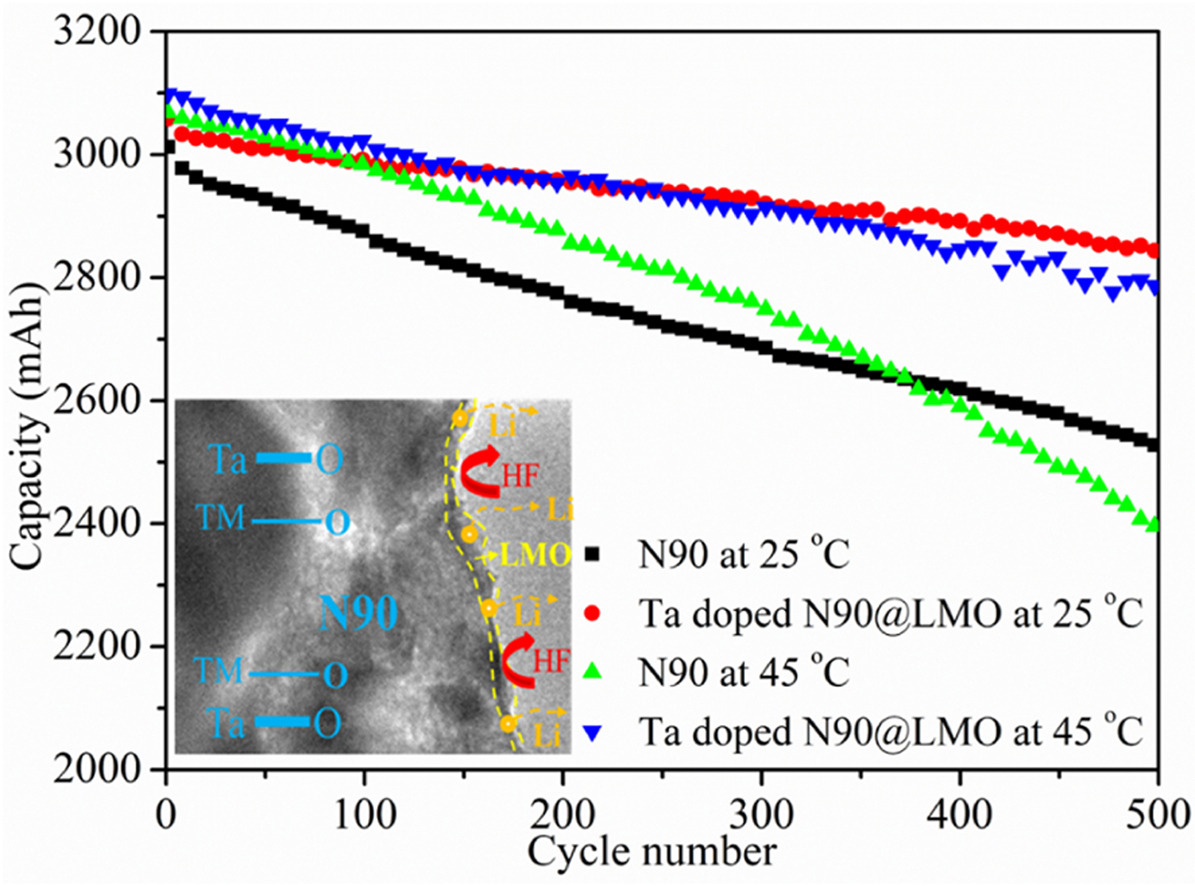

Ni-rich layered oxide with Ni molar content larger than 90% was regarded as an extremely promising candidate for cathode material applied in lithium-ion batteries owing to the significant discharging capacity and low cost. Nevertheless, rigorous cycling attenuation resulted from the crystal structure collapse and unstable particles interface deeply restrained the commercial application. In the work, LiNi0.90Co0.05Mn0.05O2 was modified by Ta5+ doping and Li2MnO3 covering, which was aimed to enhance the structure stability, defend the electrolyte attacking and promote Li+ migration during cycling. The material characterization demonstrated the cathodes after Ta5+ doping delivered the larger cell lattice parameters and higher cation ordering, which was helpful to improve the rate property and discharge capacity at low temperature. The Li2MnO3 layer was tightly adhered on the outside of LiNi0.90Co0.05Mn0.05O2, which could effectively relieve the electrolyte attacking and sustain the particle morphology integrity. As a result, 2 wt% Li2MnO3 coated Li(Ni0.90Co0.05Mn0.05)0.98Ta0.02O2 exhibited the outstanding discharge capacity of 150.2 mAh g−1 at 10.0 large current density and 140.6 mAh g−1 at −30 °C as well as the remarkable capacity retention of 93.1% after 300 cycles. Meanwhile, the pouch full batteries obtained by 2 wt% Li2MnO3 coated Li(Ni0.90Co0.05Mn0.05)0.98Ta0.02O2 also showed the more stable storage capability, cyclic property in comparison with bare LiNi0.90Co0.05Mn0.05O2.