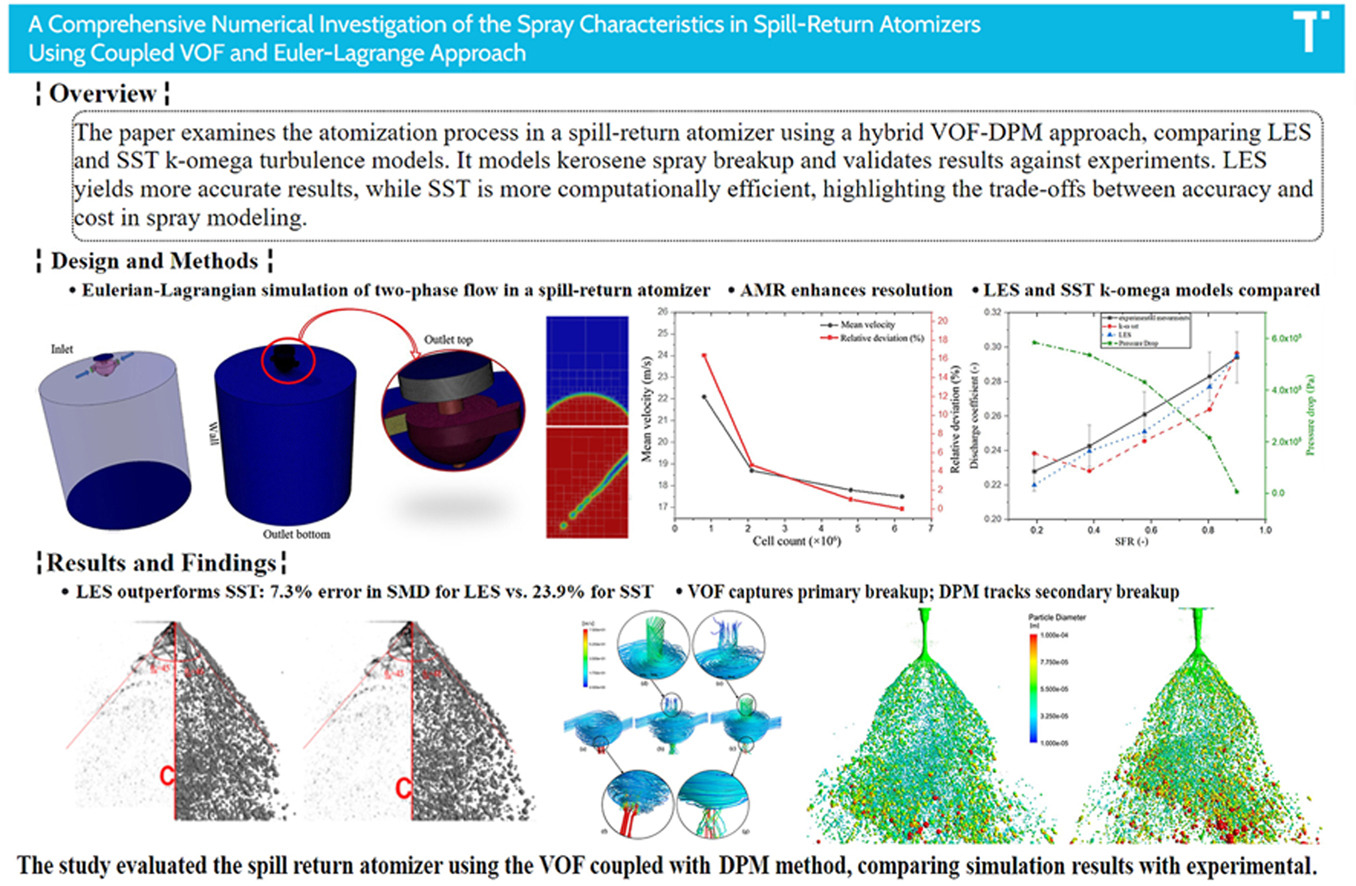

• Developed and validated a 3D two-phase flow model for spill-return atomizers using a VOF-to-DPM hybrid approach.

• Accurate prediction of droplet size distributions with a 7.3% error in ISMD using LES turbulence model.

• Identified impact of spill-line orifice design on spray cone stability and atomization efficiency.

• Four key vortex structures in the internal flow, enhancing understanding of liquid sheet breakup.

• Provided insights into spray morphology and droplet size distribution across various operating regimes.

This research paper investigates a three-dimensional, two-phase flow dynamics, and atomization characteristics of a spill return atomizer. The method includes the internal flow field, primary and secondary atomization which are modeled using the hybrid approach Volume of Fluid to Discrete Phase Model (VOF to DPM). A comparison between the Large Eddy Simulation (LES) and The k-omega Shear Stress Transport turbulence model (SST k-ω) in combination with the Volume of Fluid (VOF) model, along with the Adaptive Mesh Refinement (AMR) method, to predict the breakup of the liquid core is carried out. The investigation presents axial and tangential distributions of velocity, mean diameter, and spray cone angle of droplets at spray pressures of Spill-to-Feed Ratio (SFR) equal to 0.9. The numerical results are validated against the Phase-Doppler Anemometry (PDA) experiment. A relative error, of less than 7.3%, is recorded. The study systematically explores the spatiotemporal evolution of the flow field, including the liquid surface wave motion, liquid film characteristics, and the formation/atomization of the fluid spray cone downstream of the injector.