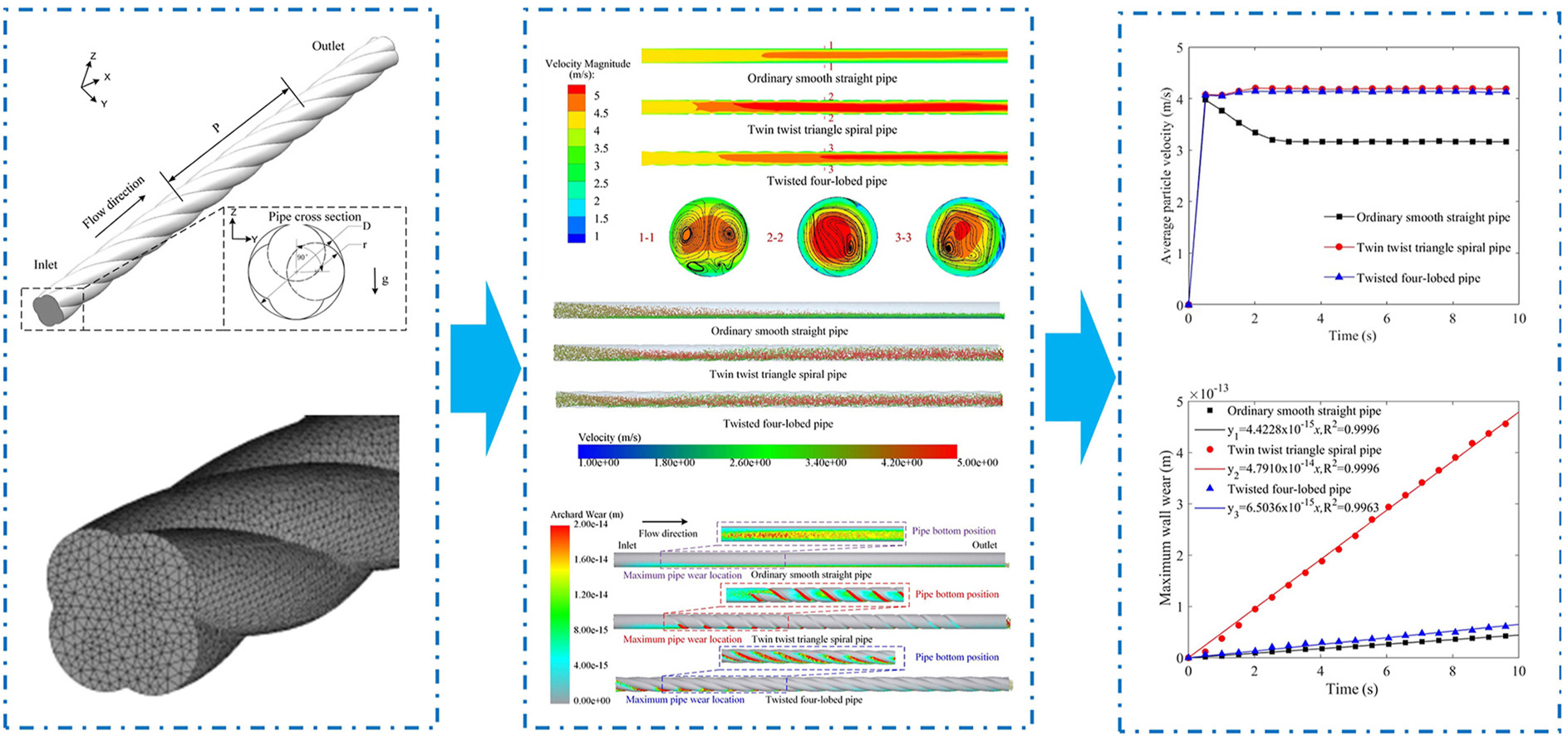

• Twisted four-lobed pipe is applied to slurry-water circulation pipe.

• Slag carrying performance of pipeline was evaluated by CFD-DEM method.

• Relationship between structure parameters and slag carrying performance and wear of pipeline is studied.

• Optimization process is used to optimize the structural parameters.

Pipeline hydraulic transportation is extensively utilized across diverse sectors, with enhancing the performance of pipeline hydrodynamic transport and minimizing erosion wear on the pipeline walls being essential for ensuring the stability of pipeline operations. This paper introduces a methodology for the hydraulic transport of a twisted four-lobed pipe, employing a numerical and erosion model developed through the CFD-DEM (computational fluid dynamics and discrete element method) coupling approach. An experimental circulating flow platform is constructed for validation purposes. The performance of the pipe is assessed by analyzing key indices including fluid velocity, pressure drop, particle trajectory, and erosion wear. The results indicate that twisted four-lobed pipe enhances fluid flow rates, facilitating particle discharge and mitigating accumulation, with reduced wear compared to the twin twist triangle spiral pipe. The analysis of structural parameters’ impact on hydraulic conveyance is also presented. These findings offer theoretical insights for optimizing pipeline performance in hydraulic conveyance while minimizing wear.