- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

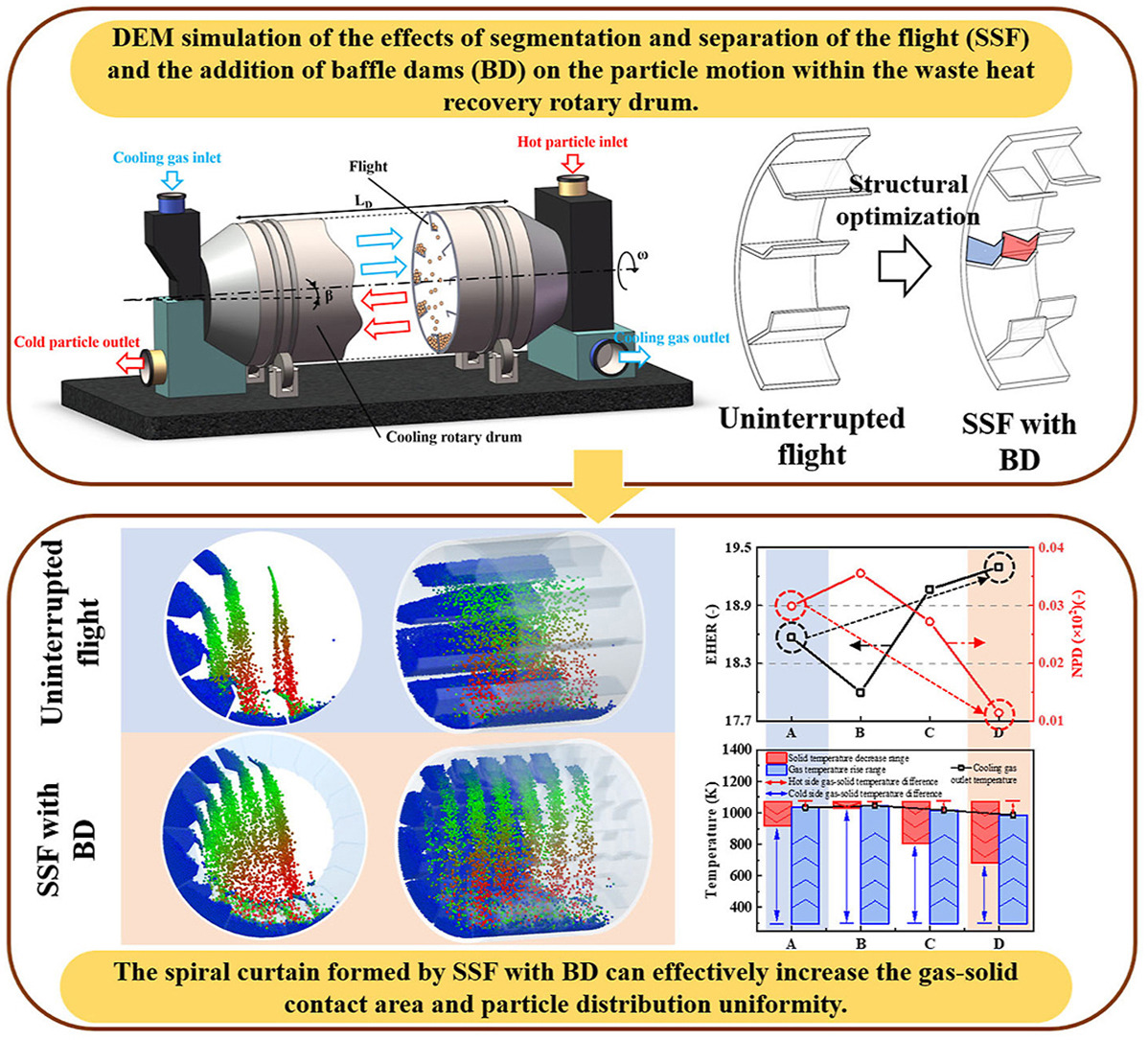

• Separated segmented flights with baffle dam were designed for rotary drum.

• Particle motion was analyzed for various flighted drums with DEM.

• Changes in axial velocity and curtain were demonstrated with long drum model.

• Segmentation and damming for flights can improve heat exchange and its uniformity.

In a waste heat recovery rotary drum with flights, particle lifting enhances gas-solid contact and introduces greater complexity to the particle motion. This study proposed strategies such as the segmentation and separation of flights (SSF) and the addition of baffle dams to establish a reasonable distribution of the particle curtain. A long drum model was developed, and DEM was employed to examine the effects of segment length, separation angle of flight, and position, height of baffle dam on particle motion and heat exchange capacity. The heat exchange efficiency of the system under the four special operating conditions was compared. The results showed that SSF enhanced the randomness of particle axial motion, while the development of the long drum model effectively identified the key factors influencing motion. The SSF formed a spiral-shaped particle curtain, exhibiting a high degree of particle distribution uniformity. The installation of the baffle dam enhanced the flight holding capacity and suppressed both transitional particle movement and backflow. With equivalent filling degree, compared to the uninterrupted flight, the SSF with bilateral baffle dam reduced the particle distribution non-uniformity by 61.72 %, while increasing the gas-solid contact area by 3.92 % and the bulk cooling temperature by 1.51 times.