- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

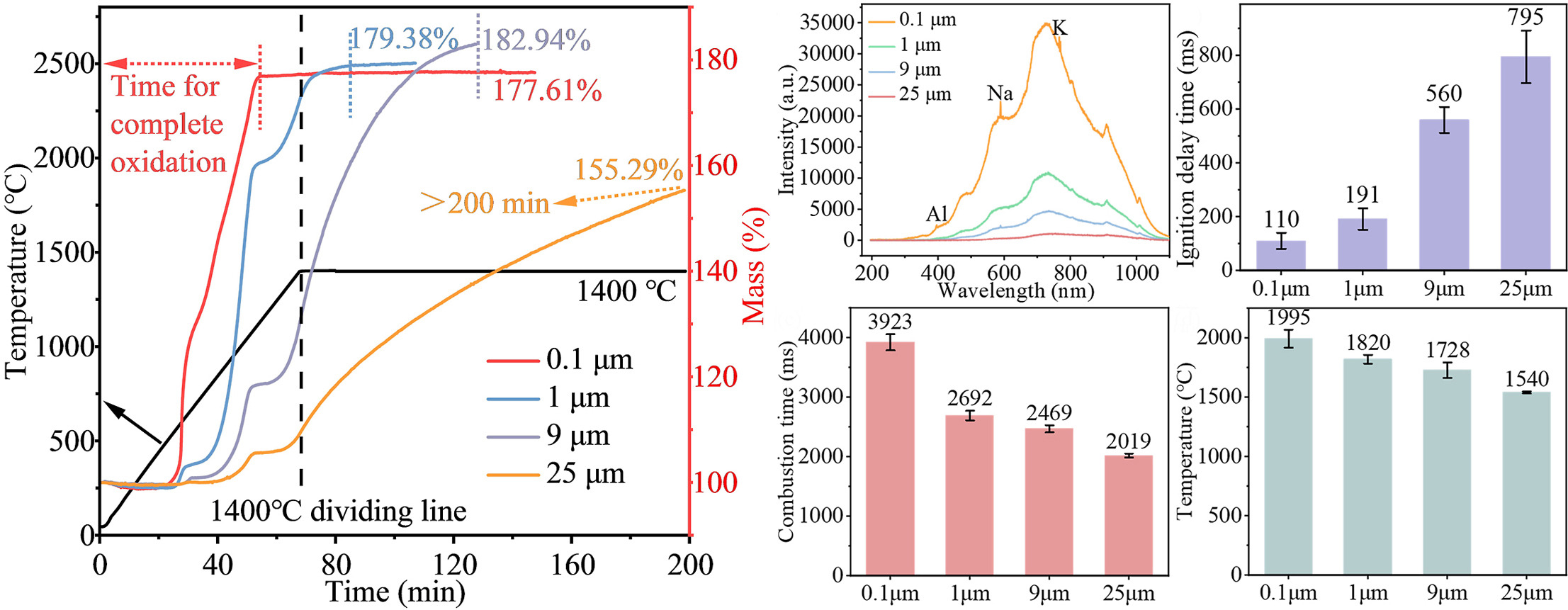

• Thermodynamic calculations and experiments were used to study effects of various factors on aluminum (Al) energy release.

• It is found that alumina shell is non-dense at 1400 °C in air.

• Pressure has little effect on thermodynamic parameters of Al/O and Al/O/C/H systems.

Although aluminum (Al) particles have been widely applied in aerospace and missile technologies, the critical factors influencing their combustion remain insufficiently studied. To address this, this work investigates the effects of multiple factors on Al particle combustion through thermodynamic theoretical calculations and experimental approaches. Thermodynamic results indicate that various oxidizing gases can chemically react with Al and release heat. Among them, the reaction between Al and oxygen exhibits the largest enthalpy change and Gibbs free energy change. In both Al/O and Al/O/C/H systems, increasing temperature reduces enthalpy change but enhances Gibbs free energy change. Pressure shows negligible effects on the system, while the influence of Al molar quantity depends on oxygen atom availability. Thermal analysis reveals that smaller particle sizes significantly increase oxidation rates. Moreover, Al particles with different particle sizes can continue to react until complete oxidation at a constant temperature of 1400 °C in air, suggesting that the alumina shell at high temperatures may be loose and porous with a non-dense structure. Combustion tests demonstrate that reducing particle size from 25 μm to 0.1 μm decreases ignition delay time by 86 % and increases combustion temperature by 30 %. Similarly, elevating oxygen concentration or pressure reduces ignition delay, enhances combustion temperature, and improves combustion efficiency. This study provides fundamental data support for constructing Al particle combustion models under complex variable environments.