- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

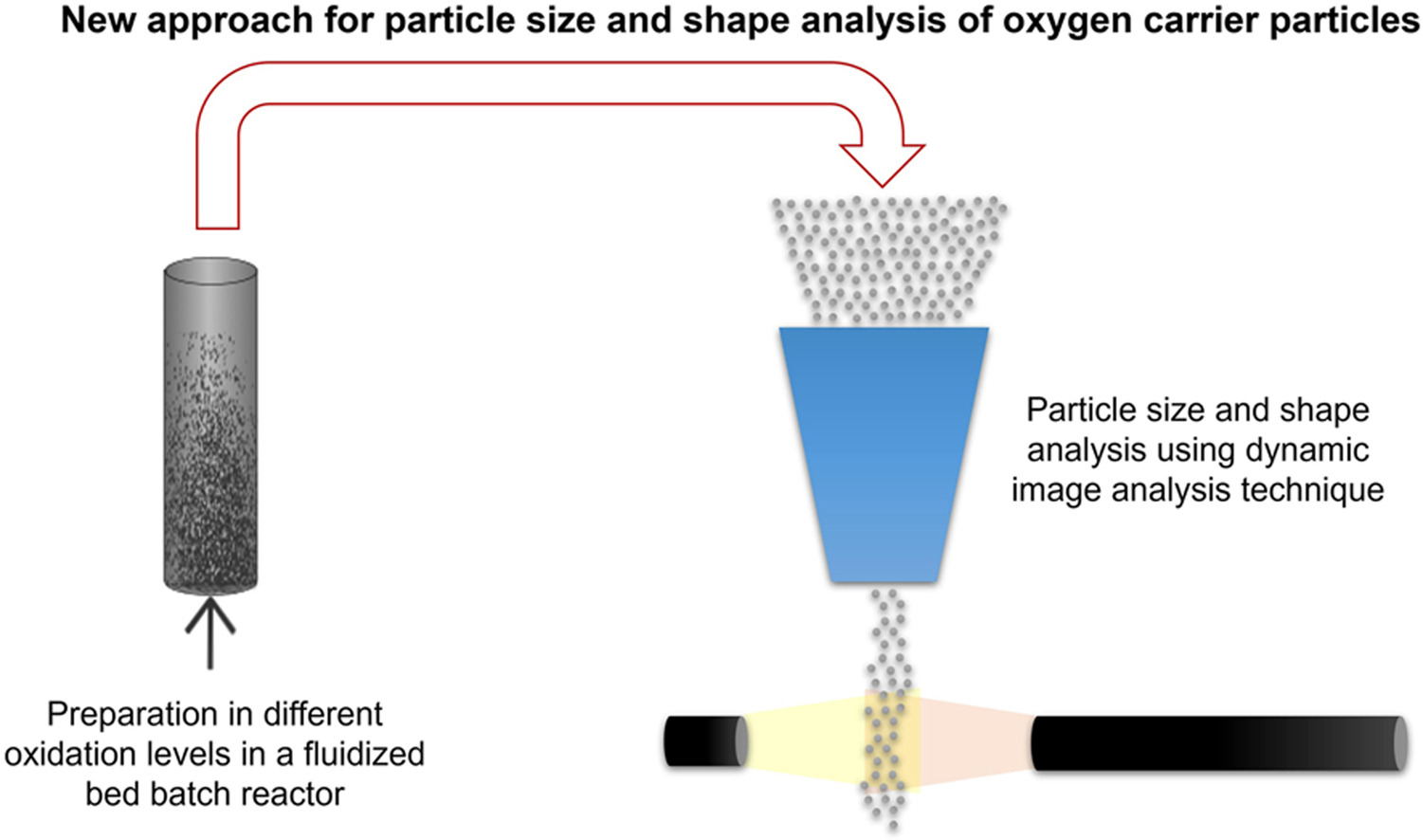

• Dynamic image analysis works well for evaluating size and shape of oxygen carriers.

• Oxidation state of oxygen carriers has minimum influence on particle size and shape.

• Exposure to operation in fluidized bed may alter particle size and shape.

One of the crucial issues in the chemical looping technology lies in its bed material: the oxygen carrier. Particle size analysis of an oxygen carrier is important since in a fluidized bed the material can only work well within a specific size range. While the favorable size ranges for oxygen carrier materials have already been reported, none of the published studies has analyzed the particle size and shape of oxygen carriers in detail. Furthermore, the effect of oxygen carriers' oxidation degree on such properties has not been considered either. This study aimed to report the particle size and shape analysis of five iron-based oxygen carriers, one natural ore, one synthetic material, and three residue products, at different oxidation degrees using dynamic image analysis (DIA). The oxygen carriers were prepared at different mass conversion degrees in a fluidized bed batch reactor. The size distribution, sphericity, and aspect ratio of the oxygen carrier particles were examined experimentally using a Camsizer instrument. Our results show that the DIA method was successfully able to analyze the particle size and shape of our oxygen carriers with satisfying accuracy for comparison. The oxidation state of the investigated materials seems to only affect the particle size and shape of oxygen carriers to a minor extent. However, exposures to redox cycles in a fluidized bed reactor may alter the particle size and shape of most oxygen carriers.