- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

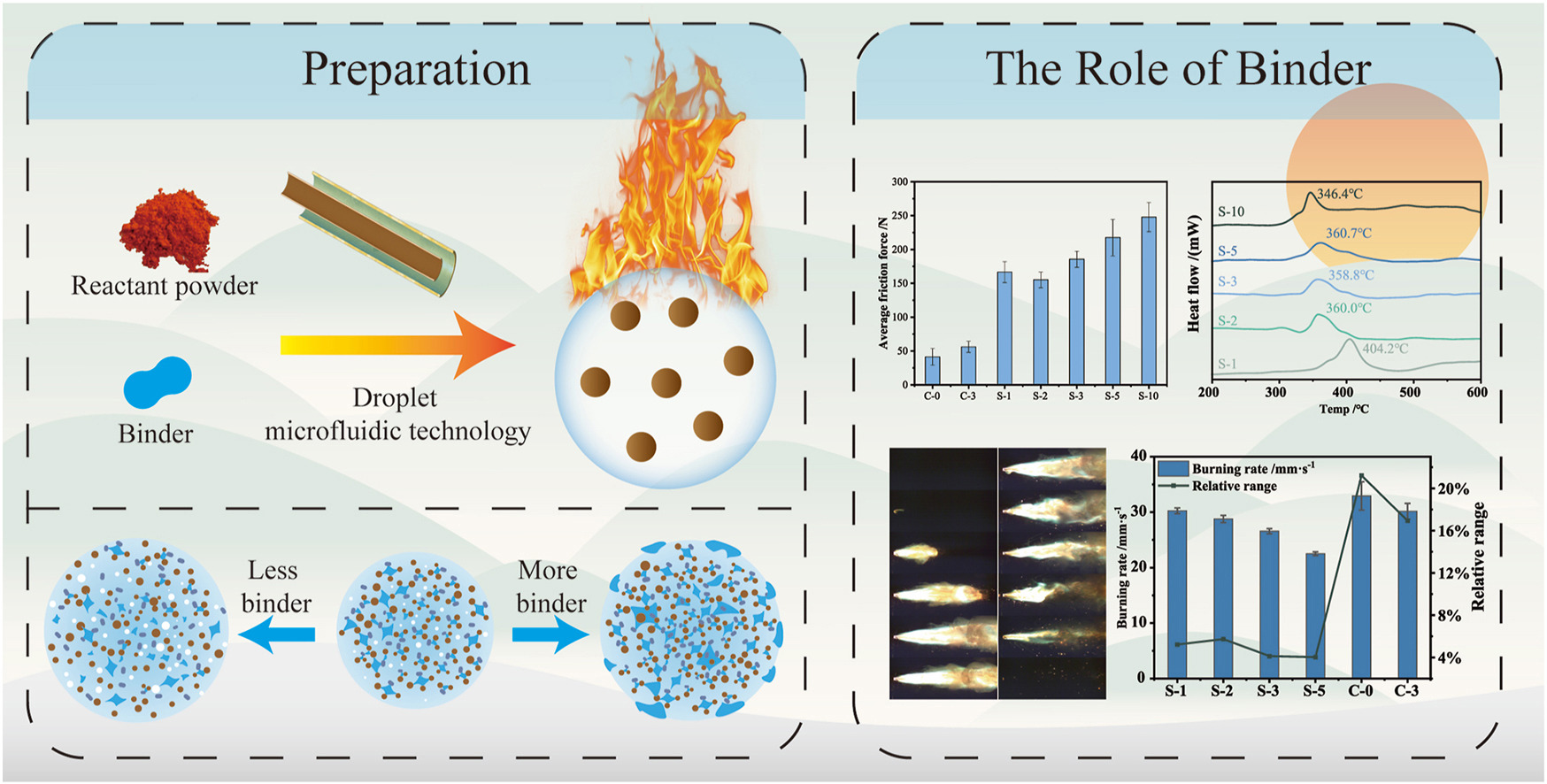

• Method to prepare reactive composite microspheres with micrometer-scale powder, showing broad application potential.

• Reactivity of composite particles is influenced by changes in binder content and resulting particle state variations.

• Droplet microfluidic technology enhances particle properties, safety, and combustion performance of reactive composites.

• Insights into binder roles in spherical reactive composites serve as a reference for other composite particles.

The strategic selection of appropriate preparation methods and binder strategies is crucial for enhancing the particle and combustion performance of pyrotechnic delay compositions (PDCs). This study, utilizing droplet microfluidics technology (DMT) and micron-scale raw materials, prepared spherical B/Pb3O4 composite particles with varying concentrations of fluorine rubber (F2604). The morphology, specific surface area, bulk density, flowability, friction sensitivity, thermal decomposition, and combustion performance of these microspheres were characterized. The results indicate that as the binder content increases, the particle size of the microspheres first decreases and then increases, the specific surface area decreases, and the bulk density increases, correlating with tighter binding of the reactant powders by the binder. Furthermore, tighter powder-to-powder binding results in a progressive decrease in the thermal decomposition peak temperature of the samples (from 404.2 °C to 346.4 °C). Additionally, increased binder content reduces the friction sensitivity and combustion rate of the samples, which is attributed to the energy absorption properties of the binder. Compared to the control group, the microsphere samples exhibit significantly enhanced bulk density, flowability, friction safety, and combustion delay precision, potentially improving the reliability of PDCs in ignition sequences.