- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

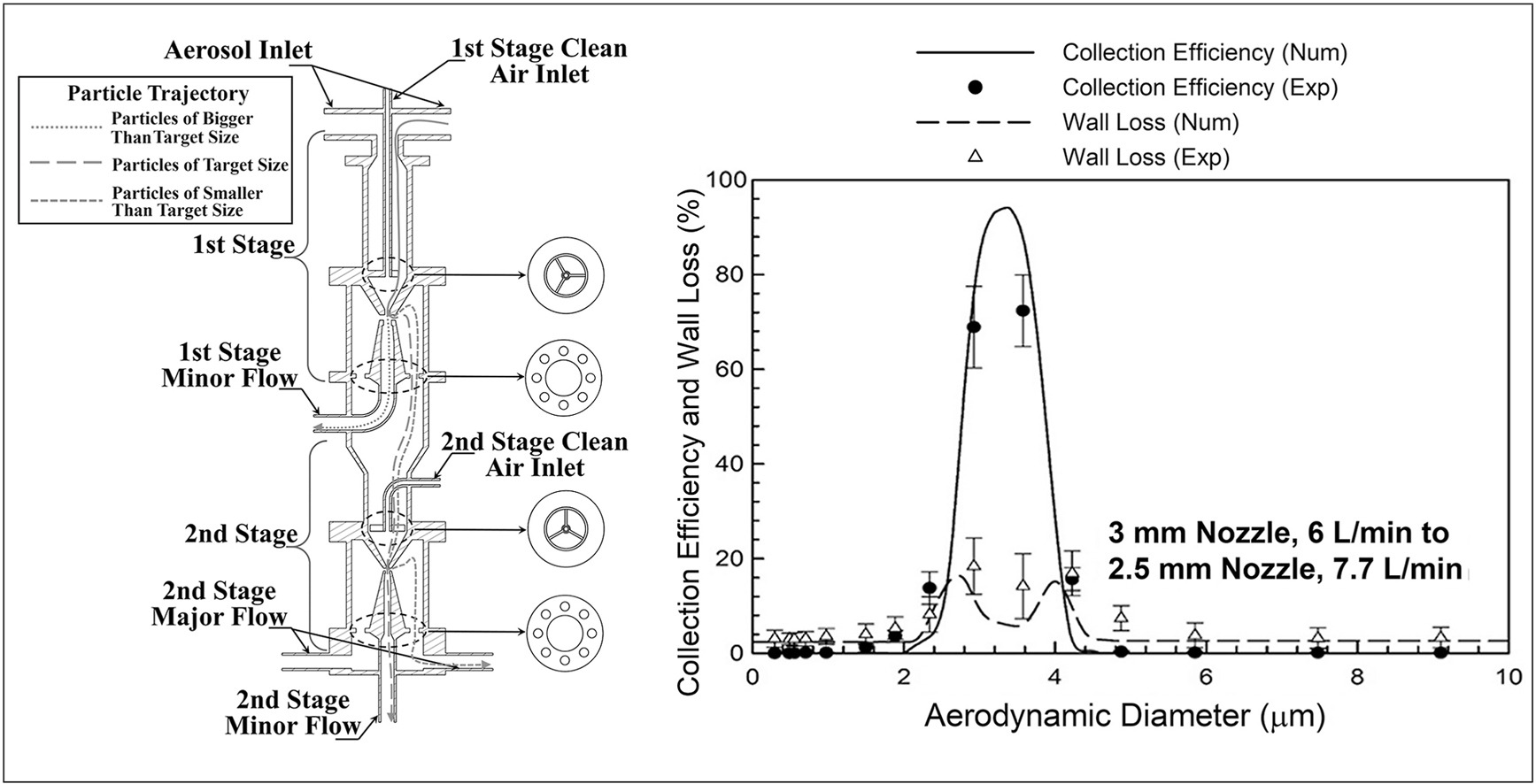

• A device to generate μm-scale solid aerosol particles within a narrow size range was developed.

• Two virtual impactors with clean air cores were connected in series.

• Target particle size range was altered by changing nozzle size and operating flow rate.

• Monodisperse aerosol particles were classified at a geometric standard deviation of 1.04–1.14.

Monodisperse particles are useful across a wide range of industrial applications, such as LCD displays, solar cells and rechargeable batteries, due to their uniformly small sizes. However, generating high volumes of monodisperse particles remains challenging. In this study, it was aimed to generate monodisperse aerosols by classifying micrometer-scale solid aerosol particles within a narrow size range. Accordingly, a new particle-size classification device with two virtual impactors connected in series and clean air cores was developed. The first-stage virtual impactor had a slightly larger cutoff size than the second-stage, and the major flow discharged from the first-stage was directed to the second-stage. The target particle size range was altered by changing the nozzle sizes in the first and second stages or by adjusting the flow rate. Subsequently, the classification performance of the two-stage virtual impactor was simulated and validated through an experiment using Arizona test dust. The implemented combinations of cutoff sizes for the first and second stages were 3.0 and 2.0 μm, 3.9 and 2.7 μm, or 6.7 and 4.8 μm. As a result, monodisperse aerosol particles were classified at a geometric standard deviation of 1.04–1.14 and a particle size range of 2–6.7 μm. The two-stage virtual impactor developed herein may be useful for various research and performance evaluations, as it can classify micrometer-scale solid particle aerosols that exhibit high monodispersity.