- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

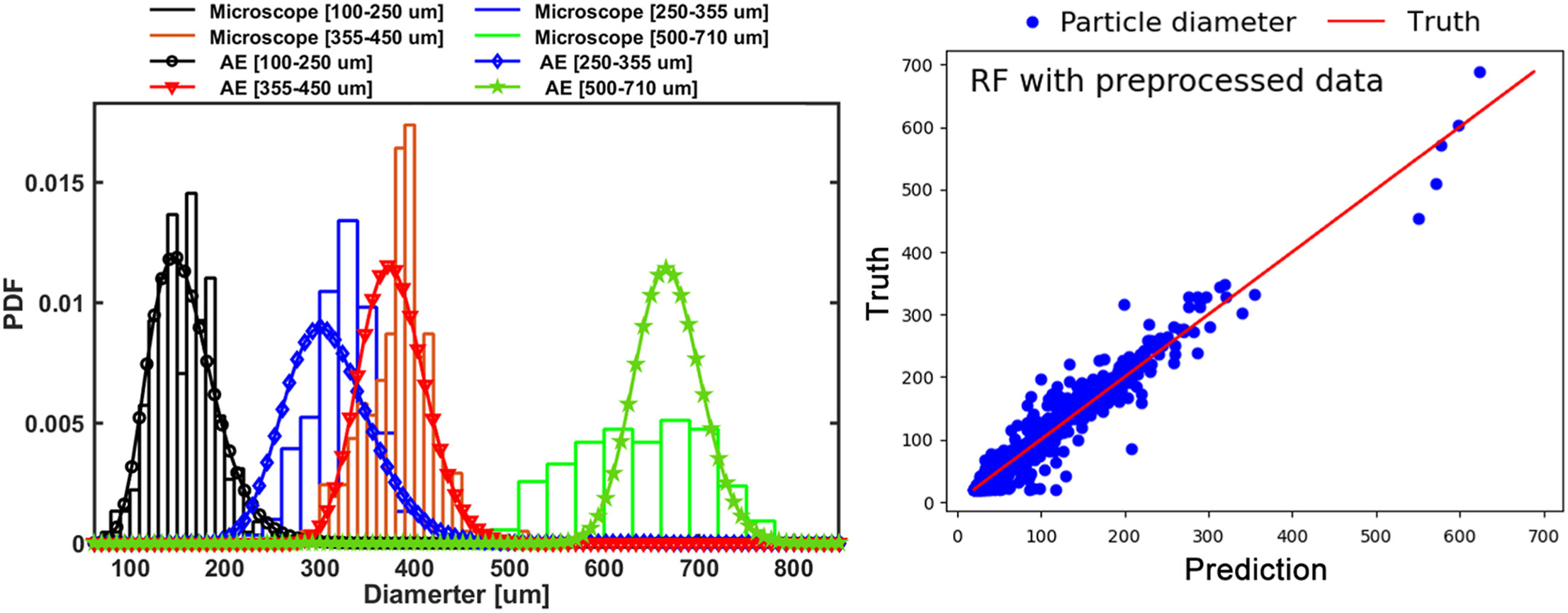

• A combination of an acoustic emission (AE) techniques with machine learning (ML) for fluid particle flows is developed.

• A theoretical model for the generation of AE signal in gas-solid flow is presented.

• An inversion algorithm to invert AE signal to particle size distribution is reported.

• ML approaches are applied to predict particle sizes based on the AE signal features.

In this work, a combination of an acoustic emission (AE) technique and a machine learning (ML) algorithm (Random Forest (RF) and Gradient Boosting Regressor (GBR)) is developed to characterize the particle size distribution in gas-solid fluidized bed reactors. A theoretical approach to explain the generation of acoustic emission signal in gas-solid flows is presented. An AE signal is generated in gas-solid fluidized beds due to the collision and friction between fluidized particles as well as between particles and the bed inner wall. The generated AE signal is in the form of an elastic wave with frequencies >100 KHz and it propagates through the gas-solid mixture. An inversion algorithm is used to extract the information about the particle size starting from the energy of the AE signal. The advantages of this AE technique are that it is a cheap, sensitive, non-intrusive, radiation-free, suitable for on-line measurements. Combining this AE technique with ML algorithms is beneficial for applications to industrial settings, reducing the cost of signal post-processing. Experiments were conducted in a pseudo-2D flat fluidized bed with four glass bead samples, with sizes ranging from 100 μm to 710 μm. AE signals were recorded with a sampling frequency of 5 MHz. The AE signal post-processing and data preparation for the ML process are explained. For the ML process, the AE frequency, AE energy and particle collision velocity data sets were divided into training (60%), cross-validation (20%) and test sets (20%). Two ensemble ML approaches, namely Random Forest and Gradient Boosting Regressor, are applied to predict particle sizes based on the AE signal features. The combination of these two models results in a coefficient of determination (R2) value greater than 0.9504.