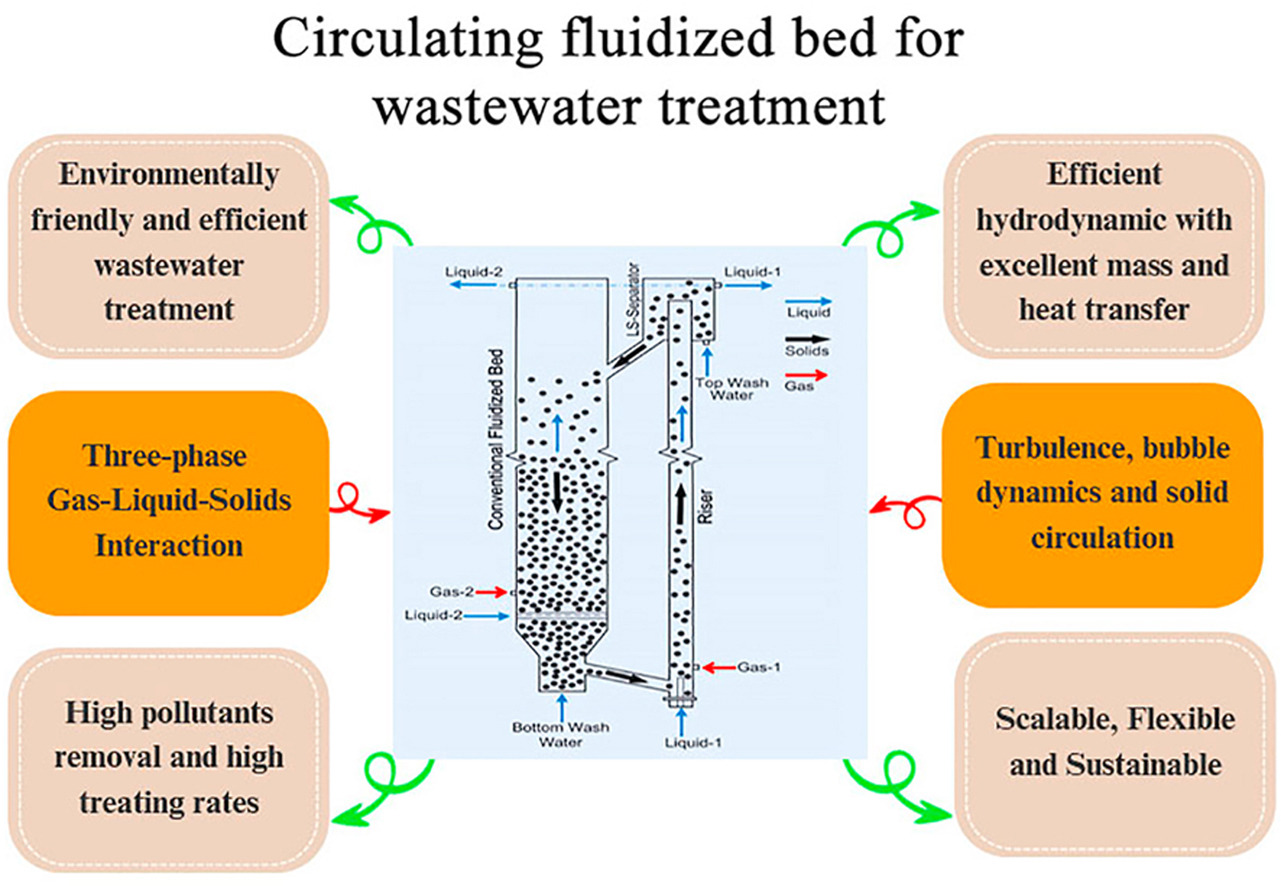

• CFB supports gas-solid and gas-liquid-solid systems for wastewater treatment.

• Three-phase CFB enhances mass/heat transfer, improving pollutant removal efficiency.

• CFB technology is energy-efficient and compact, ideal for wastewater effluent treatment.

• Liquid phase in CFB enables biomass conversion, gas-liquid reactions, and catalysis.

• CFB reactor design maximizes wastewater-contact for high pollutant removal rates.

This review investigates the gas-liquid-solid circulating fluidized bed (GLS-CFB) technology for wastewater treatment by exploring its operational parameters and diverse applications for wastewater cleaning. The versatile CFB reactor system operates in both two-phase and three-phase modes, offering advantages for various industrial applications through distinct operational configurations. Incorporating the liquid phase into the standard gas-solid system of the three-phase GLS-CFB enables the study of reactions involving liquid media, gas-liquid interactions, and biochemical processes. These advanced features improve mass transfer and reaction control. GLS- CFB systems promote effective pollutant removal by enhancing the interaction between wastewater and treatment agents, which supports better microbial metabolism and pollutant transfer. The GLS-CFB system is efficient and compact, allowing for treating diverse wastewater types regardless of their size distribution. The novelty of this review lies in exploring the hydrodynamic properties of GLS-CFB and demonstrating its potential for scalable, efficient wastewater treatment across various industrial sectors.