Lei, H., Wang, W., Jiang, L., Chang, Z., Anwar, H., Dong, B., . . . Liu, M. (2025). Selective lithium leaching from spent Li(MnyFe1-y)PO4 cathodes with gradient in-situ-oxidation of Na2S2O8. Particuology, 102, 207-215. https://doi.org/10.1016/j.partic.2025.04.015

Selective lithium leaching from spent Li(MnyFe1-y)PO4 cathodes with gradient in-situ-oxidation of Na2S2O8

Hao Lei a, Wei Wang b *, Longjin Jiang c, Zhidong Chang a *, Hira Anwar a, Bin Dong a, Dekun Gao d, Zhiyi Chen a, Mingming Liu a

a School of Chemistry and Biological Engineering, University of Science and Technology Beijing, Beijing, 100083, China

b State Key Laboratory of Biochemical Engineering, Institute of Process Engineering, Chinese Academy of Sciences, Beijing, 100190, China

c Anhui Chaoyue Environmental Protection Technology Co., Ltd, Chuzhou, 239060, China

d Anhui Huihong Technology Co., Ltd, Chuzhou, 239060, China

10.1016/j.partic.2025.04.015

Volume 102,

July 2025,

Pages 207-215

Received 28 February 2025, Revised 2 April 2025, Accepted 16 April 2025, Available online 29 April 2025, Version of Record 15 May 2025.

E-mail:

weiwang@ipe.ac.cn; zdchang@ustb.edu.cn

Highlights

• Preferential extraction of lithium from spent LMFP cathodes and regeneration as Li2CO3 were proposed.

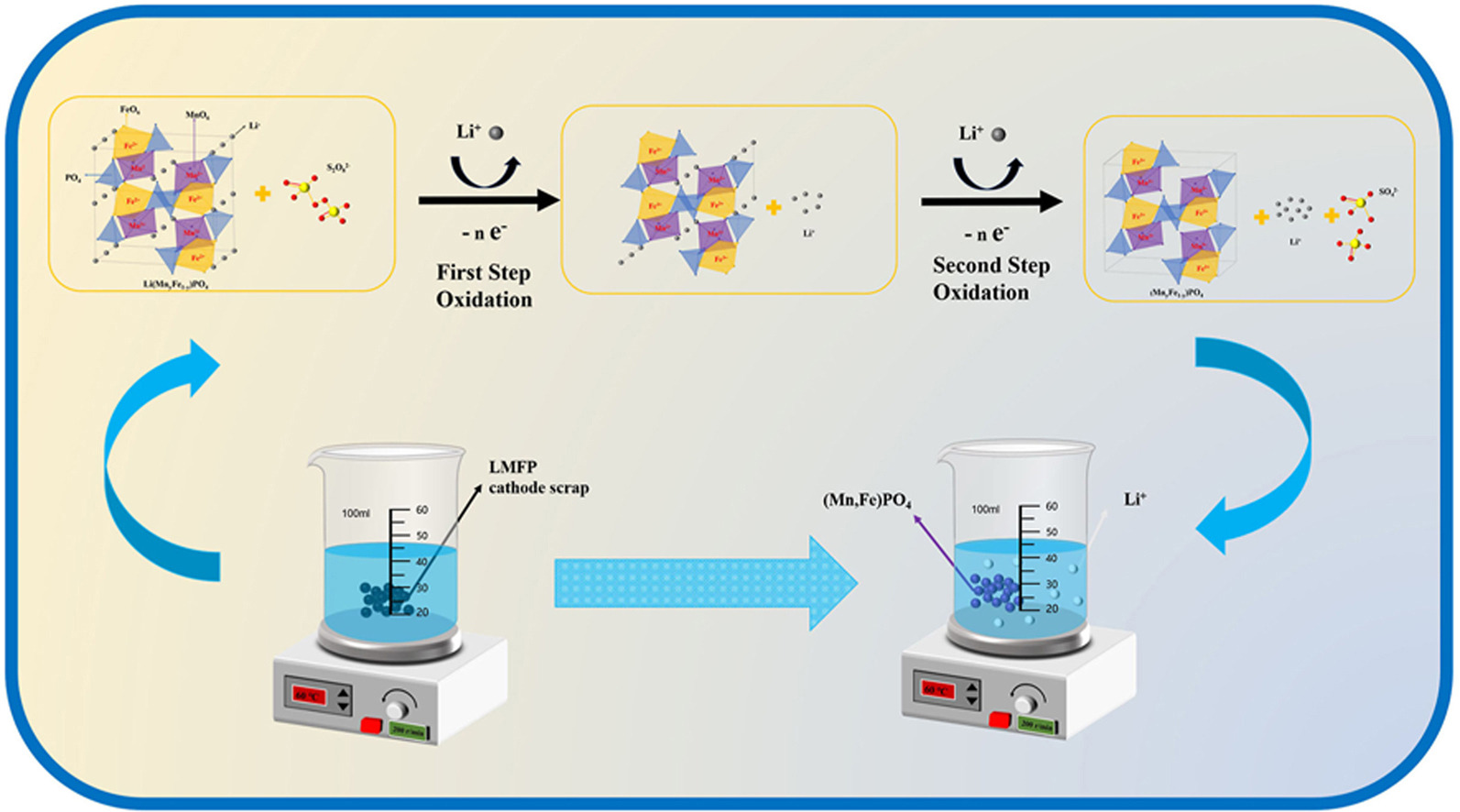

• Gradient in-situ-Oxidation leaching mechanism was proposed.

• Li was selectively extracted through converting it into water-soluble Li2SO4, while water-insoluble (Mn,Fe)PO4 was immobilized in the residue.

• Extraction rate of Li was 97.4 % along with a selectivity of 94.37 %, respectively.

Abstract

The recovery of lithium from spent lithium iron manganese phosphate batteries is crucial for the efficient utilization of lithium resources and for alleviating supply constraints. This study proposes a selective lithium recovery method using a Na2S2O8 leaching system for spent lithium iron manganese phosphate battery cathodes. Na2S2O8 was selected based on an analysis of the thermodynamic data of each component in the leaching system. Essential leaching parameters, including H2SO4 dosage, Na2S2O8 dosage, leaching time, and leaching temperature were systematically investigated. The results showed that under the optimized experimental conditions, the lithium leaching rate reached 97.4 % with a selectivity of 96.24 %. The recovered Li2CO3 product meets battery grade requirements.

Keywords

Spent LiMn0.6Fe0.4PO4 batteries; Selective leaching of lithium; In-situ oxidation; Gradient oxidation