- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

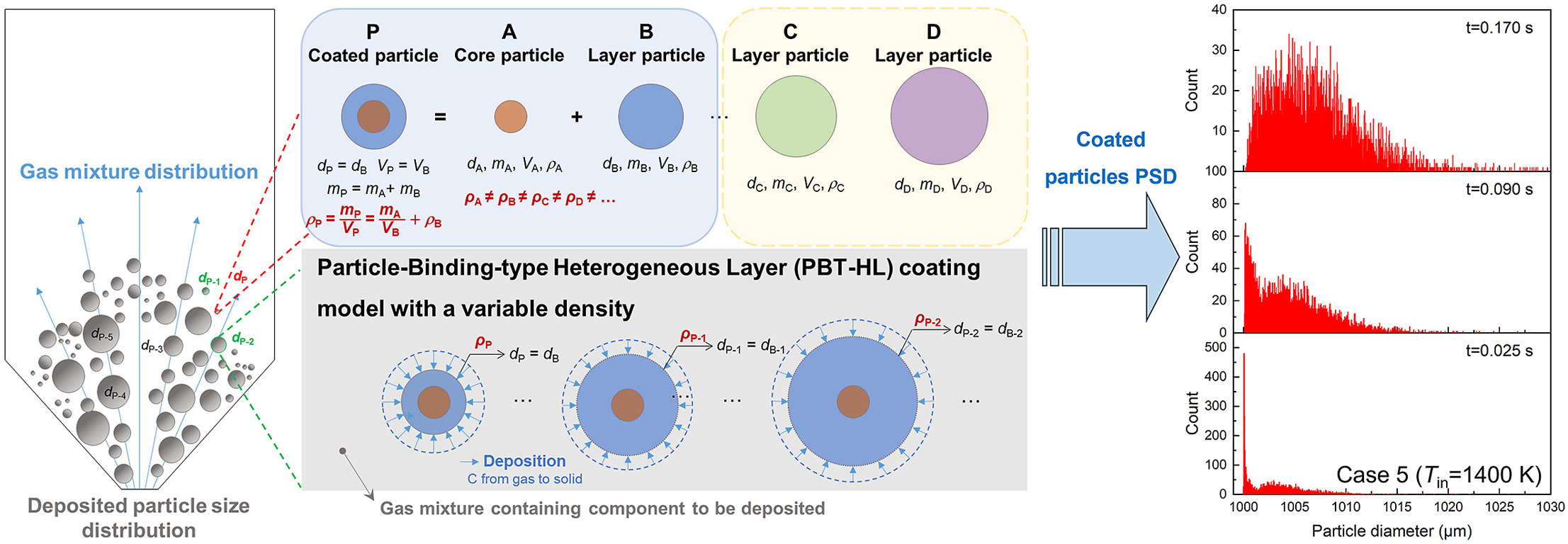

• A particle-binding-type heterogeneous layer (PBT-HL) coating model was proposed.

• Influence of fluidization on deposition rate was systematically investigated.

• Intra-particle coating uniformity was depicted by non-concentric binding model.

• CFD software was coupled with adjustable in-house code to achieve the novel model.

Preparation of coated fuel particles using the fluidized bed-chemical vapor deposition (FB-CVD) process is a key step in the production of nuclear fuel particles for high-temperature gas-cooled reactors (HTGRs). The process of applying four coating layers on high-density uranium dioxide kernel particles results in an increase in particle size and a decrease in density. Most existing coating models at the single-particle scale assume homogeneous coating under thin layer conditions, which makes it difficult to accurately describe the actual evolution process of coated particles preparation. Therefore, this study proposed a particle-binding-type heterogeneous layer (PBT-HL) model combined the binding concept with the CFD-DEM method, which accounts for dynamic changes in the density of coated particles. Then model validation in terms of gas-solid interaction and mass transfer, and coating condition parameter analysis were given at first. The results showed that changes in operational parameters such as the layer density, loading capacity, and inlet gas velocity can affect the spouted fluidization state, further influencing the deposition rate and coating effectiveness. These findings also suggested that the heterogeneous coating model in binding configuration can be further developed to study the anisotropy of single-particle layer thickness quantitatively. In summary, the variable-density PBT-HL model approximates the actual coating layer preparation process more closely, aiding in the acquisition of coating process information and guiding the optimization of coating techniques. The proposed heterogeneous coating model also holds potential for further development to characterize the intra-particle uniformity and the conformality feature of FB-CVD technique in the future.