- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

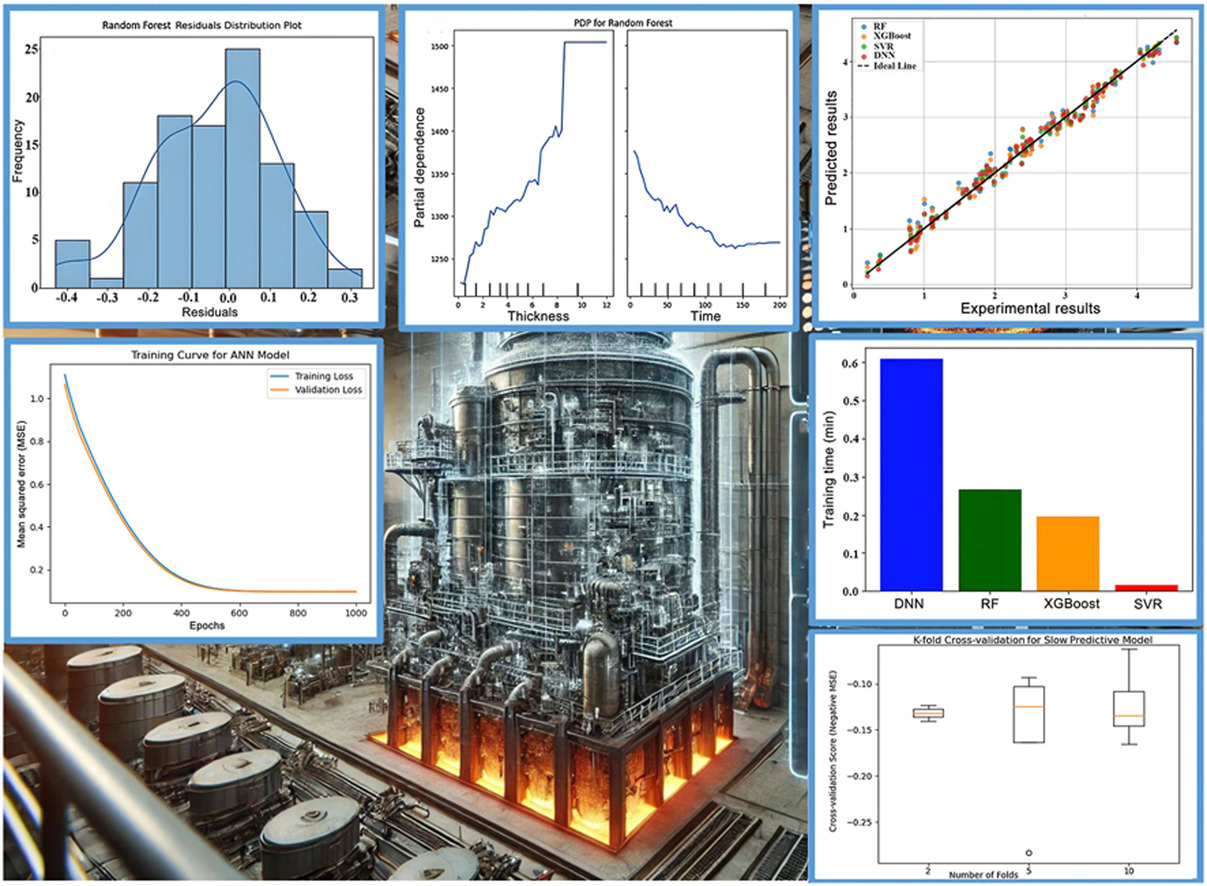

• Machine learning framework explores critical combustion parameters.

• High accuracy was achieved with Random Forest and XGBoost.

• Support Vector Regression shows superior speed in training.

• Correlation analysis shows strong ties between deposit thickness, time, and heat flux.

Predicting ash accumulation in industrial environments is crucial for improving operational efficiency, enabling proactive maintenance, reducing downtime, and optimizing plant performance. Understanding of these processes requires the analysis of key parameters, including time, heat flux, particle size, velocity, excess air ratio, furnace temperature, heat load, and oxide concentrations, with a particular focus on deposition thickness. Traditional methods often fail to capture the complexity of these interactions, necessitating innovative approaches for accurate prediction and analysis. The experimental data, along with four algorithms, i.e. Support Vector Regression (SVR), Random Forest (RF), Deep Neural Network (DNN), and Extreme Gradient Boosting (XGBoost), were employed to analyze 20 features, providing a robust evaluation of their predictive capabilities. Furthermore, the use of SHAP (SHapley Additive Explanations) values introduces a novel dimension to the study, enabling interpretability and transparency in understanding the contribution of each feature to the model's predictions. The results demonstrate exceptional predictive accuracy for the RF and XGBoost models, achieving an R2 value of 0.99 and minimal mean absolute errors (MAE). A novel comparison of training times reveals that SVR outperforms the other algorithms in speed due to its simpler structure, making it highly efficient for real-time applications. Correlation analysis identifies strong relationships between deposition thickness and key parameters such as time, heat flux, and deposition probability at varying surface temperatures. Time directly influences deposition thickness, as particles accumulate and sinter over prolonged operation. Heat flux drives particle movement through thermophoresis, affecting surface adhesion and increasing deposition probability. Surface temperature modulates particle adhesion and slag viscosity, with optimal temperatures maximizing stickiness and deposition probability.