- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

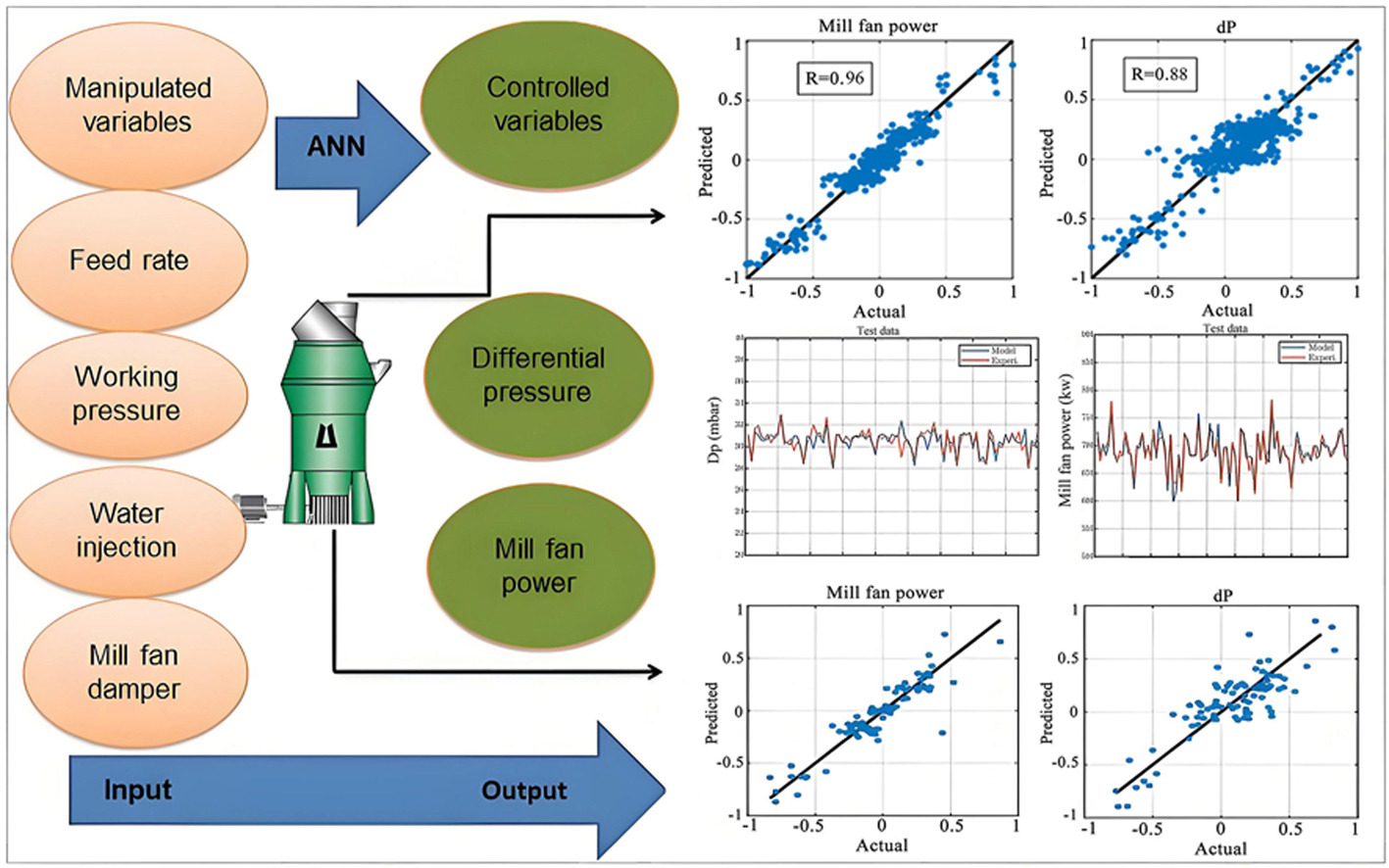

• MLP model results provided a more robust prediction than RBF and GMDH.

• MLP showed the highest accuracy and could predict the mill fan power and differential pressure.

• MLP revealed that feed rate, pressure, water injection, and fan dampers affect ventilation.

• Input-output relationships provided a more detailed insight into mill ventilation.

• Modeling revealed material transportation depends on differential pressure and mill fan power.

Vertical Roller Mills)VRM (are highly favored in cement due to low power consumption, increased capacity, and process simplification. The VRM's grinding process involves a variety of operating parameters, including process-controlled and process-manipulated variables. Therefore, understanding interactions between operation variables and power consumption would be essential for sustainable ground material transportation during the ventilation process in the mill. A few investigations were conducted to model the ventilation and power consumption of VRMs. Using an Artificial Neural Network)ANN) model on large-scale industry problems could help understand how VRM variables interact and encourage controlling ventilation for long-term operations and altered production. The deficiencies were resolved by developing the ANN models such as Multi Layer Perceptron (MLP), Radial Basis Function (RBF), and Group Method of Data Handling (GMDH) for modeling differential pressure and mill fan power draw of a VRM grinding circuit to address the effectiveness of operating variables. The MLP model had the highest level of prediction accuracy for modeling, with a coefficient of predictive accuracy (R-value) of 0.96. The MLP assessment indicated that the most influential controlled variables were the feed rate, working pressure, water injection, and mill fan damper on the differential pressure and mill fan power. These results are consistent with the actual operating state of the VRM grinding circuit. Such an ANN model for a VRM can train operators, control the process, save time and energy, reduce laboratory work and scale issues, and enhance the operation's sustainability.