- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

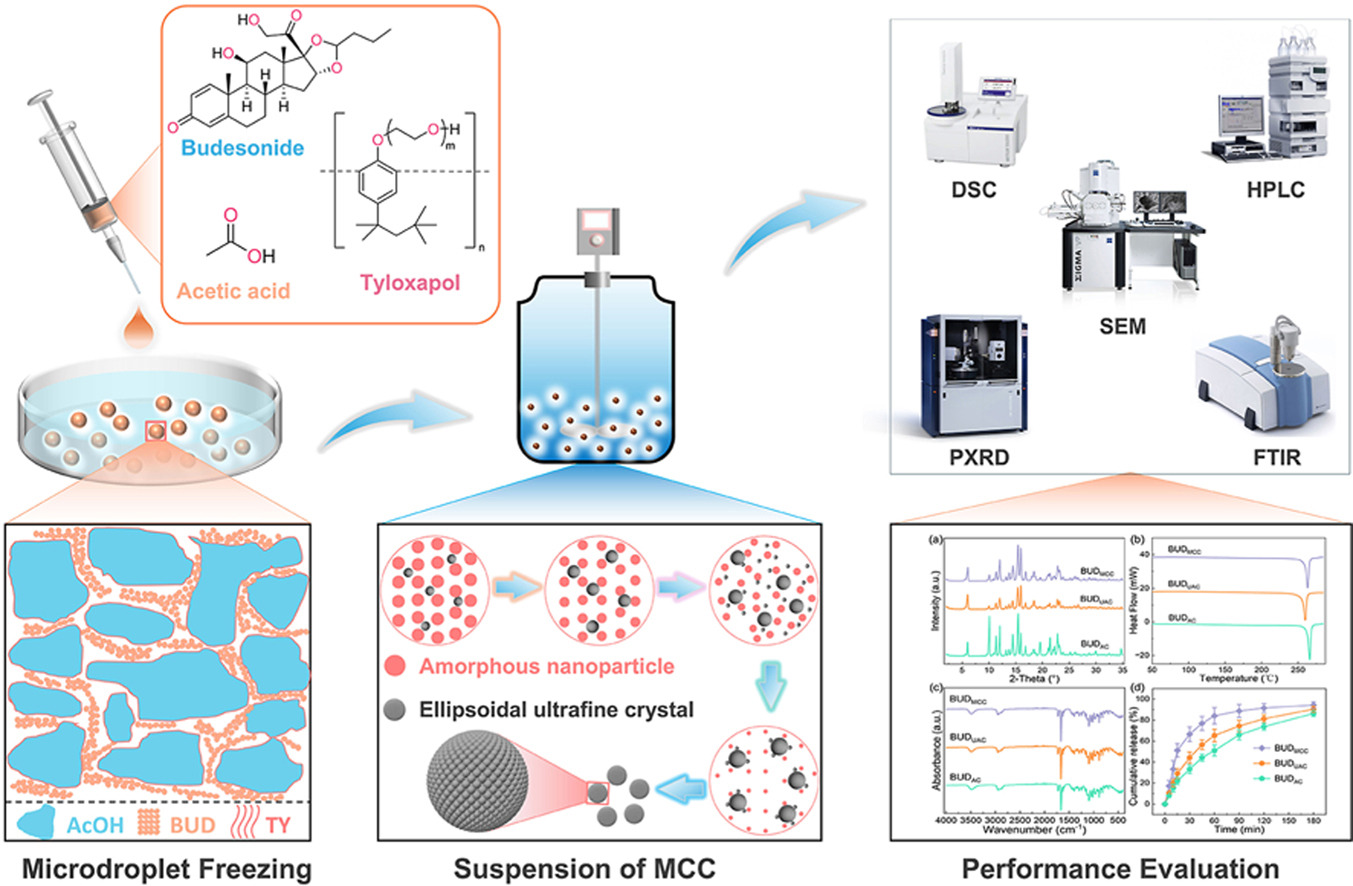

• Microdroplet cryo-crystallization was proposed to prepare ultrafine crystals.

• Engineering budesonide ultrafine crystals with superior size, shape, and crystallinity.

• Revealing the phase transformation mechanism of nanoprecursors during suspension process.

• MCC-BUD microcrystals exhibit superior dissolution performance compared to those produced by conventional methods.

Inhalation therapies are pivotal for treating pulmonary diseases, yet their efficacy critically depends on the physicochemical properties of drug particles. This study introduces a novel microdroplet cryo-crystallization (MCC) technique to fabricate inhalable budesonide (BUD) particles. The MCC process combines rapid cryogenic freezing of drug-loaded microdroplets in liquid nitrogen, followed by additive-guided suspension crystallization in an anti-solvent environment. Cryogenic freezing suppresses molecular mobility and prevents aggregation, preserving uniform solute distribution. Subsequent controlled crystallization in the anti-solvent system enables precise tailoring of nanoparticle morphologies while avoiding supersaturation-driven amorphization. Systematic optimization identified MCC conditions yielding BUD ultrafine crystals with a volume median diameter of 3.0 μm, >94 % sphericity, >98 % crystallinity, and minimal hygroscopicity (<0.5 %). Compared to conventional air-jet milled BUD (∼90 % crystallinity and ∼3 % hygroscopicity), the MCC-engineered particles exhibit significantly improved physicochemical stability and dissolution performance (94 % in 180 min). The MCC strategy decouples cryogenic freezing and phase transformation, avoiding top-down limitations (e.g., milling-induced amorphization) and bottom-up issues (uncontrolled nucleation/aggregation) to achieve scalable and highly precise production of inhalable drug particles.