- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

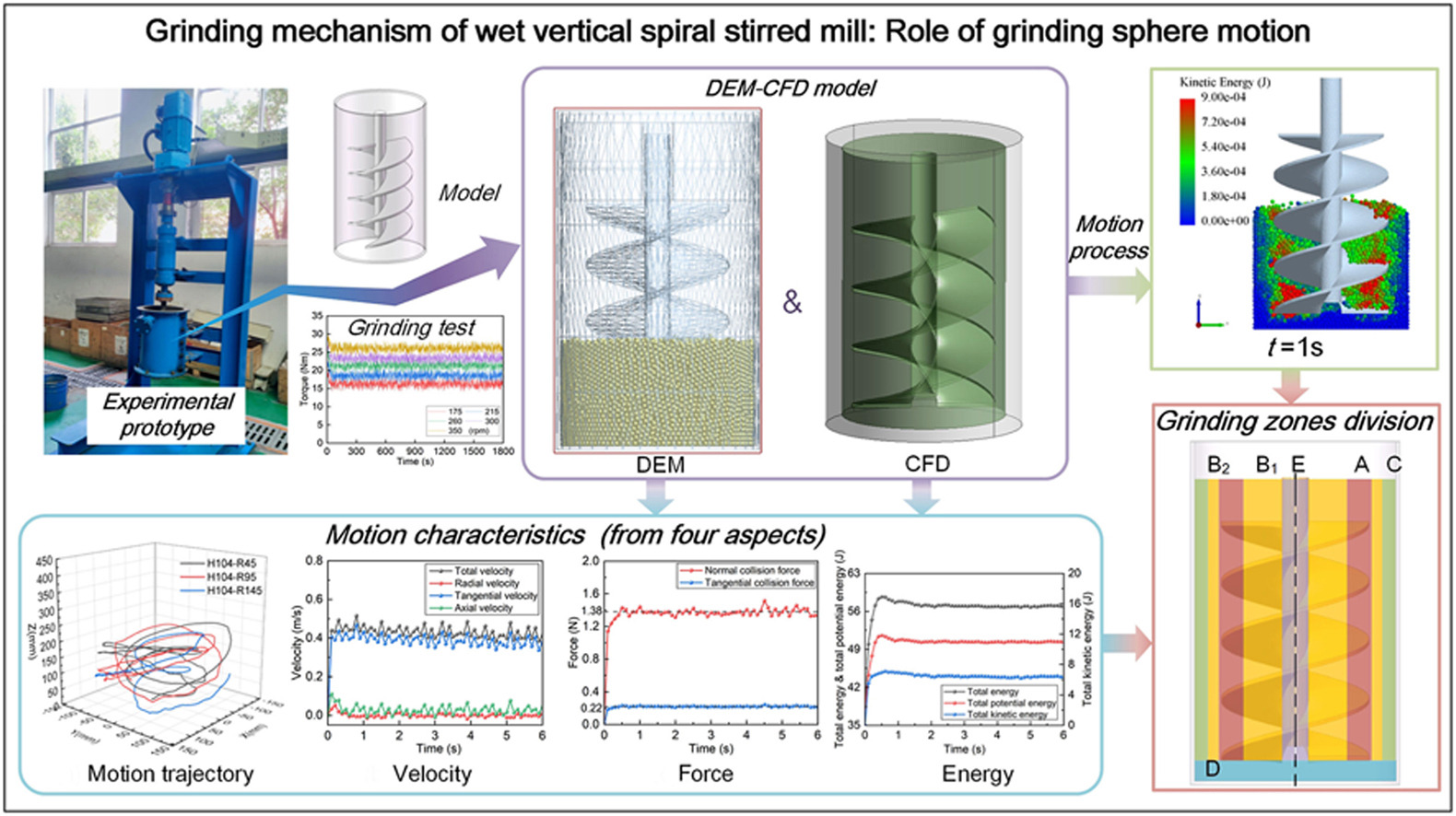

• A DEM-CFD model of experimental vertical stirred mill is established.

• Grinding sphere motion is analyzed from trajectory, velocity, force and energy.

• Five grinding zones are divided to reflect regional differences in grinding contribution.

• Motion characteristics will help to better understand the grinding mechanism.

The grinding sphere is the main ultra-fine grinding medium for the vertical spiral stirred mill, and its motion characteristics have a significant impact on grinding efficiency. A DEM-CFD model of an experimental mill was established, and the accuracy was verified through experiment. The motion characteristics of grinding spheres were systematically analyzed from four aspects: motion trajectory, velocity, force and energy. The results showed that the motion trajectories of the grinding spheres at the cylinder bottom are the shortest, which can be defined as the inert spheres. The trajectory length increases continuously as the height increases in the cylinder, while it increases first and then decreases with the increase of the radial distance. The velocity of grinding spheres near the agitator blade is the highest, while it is lowest at the cylinder wall. By comparing the total, radial, tangential and axial velocities, it was found that its motion mode is mainly tangential motion around the axis, and the axial and radial velocities are very small. The kinetic energy distribution of the grinding spheres is basically the same as the total velocity. The normal collision force of the grinding sphere is 6 times of the tangential collision force, but the tangential collision energy is about 1.4 times of the normal collision energy. Last, five grinding zones were established to characterize the contribution of grinding spheres inside the cylinder to the grinding efficiency. These results will help to understand the grinding mechanism and provide theoretical guidance for the structural design.