- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

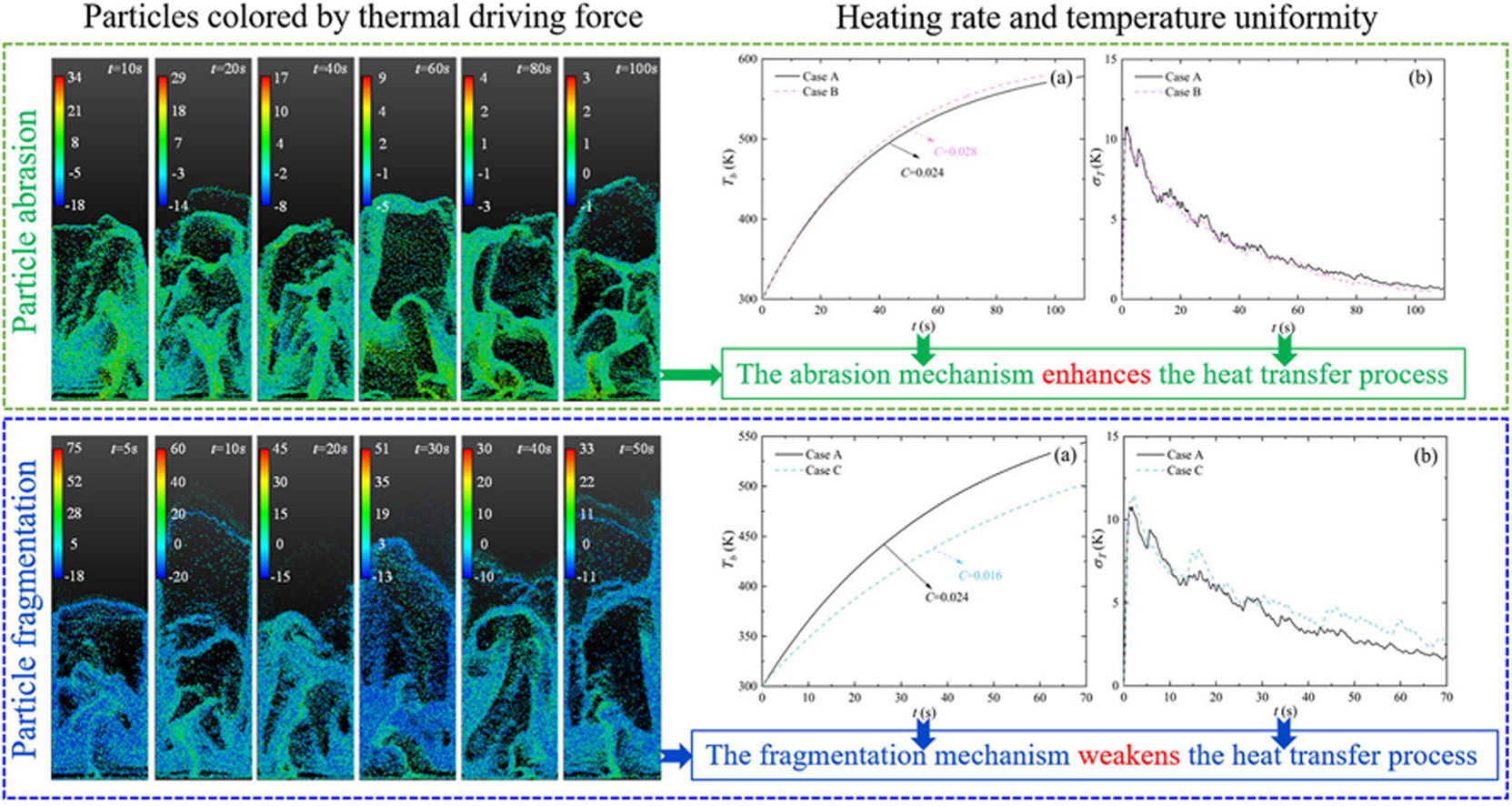

• A CFD-DEM model coupled with particle abrasion and fragmentation models was developed.

• Distribution characteristics of particles in the bed under different wear mechanisms were investigated.

• Effects of particle size reduction due to wear on bed heat transfer and temperature response were revealed.

• Effects of different wear mechanisms on bed temperature rise rate and temperature uniformity were presented.

Particle wear behavior significantly affects combustion stability and operational costs. To reveal the underlying effects of particle size reduction on the heat transfer process, which are difficult to obtain experimentally, this study proposes a novel particle wear model. The model is experimentally calibrated and subsequently incorporated into a heat-fluid CFD-DEM platform. This is the first study to numerically investigate the impact of particle size reduction due to wear on the heat transfer characteristics in a fluidized bed. This study investigates the fluid dynamic and thermal behavior of particles after wear. It provides information on the system's macroscopic gas-solid flow regime (characterized by particle size and temperature distribution), the time-varying rules of particle wear and fragmentation rate, bed particle size distribution, and the relationship between single-particle diameter and temperature under different wear mechanisms. The primary innovation of this work lies in assessing the impact of different wear mechanisms on the key parameters (heating rate and temperature uniformity) during the heating process. Based on these findings, practical guidance is provided for optimizing industrial processes (adjusting particle flow patterns, optimizing debris distribution, and enhancing temperature monitoring at the bed bottom). The results reveal that different wear mechanisms lead to distinct distribution characteristics of particles within the bed. The abrasion mechanism enhances the heat transfer process, resulting in an approximately 16 % increase in the heating rate coefficient (C) and a 6 % improvement in temperature uniformity. In contrast, the fragmentation mechanism weakens the heat transfer process, leading to an approximately 33 % decrease in C and a 21 % reduction in temperature uniformity.