- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

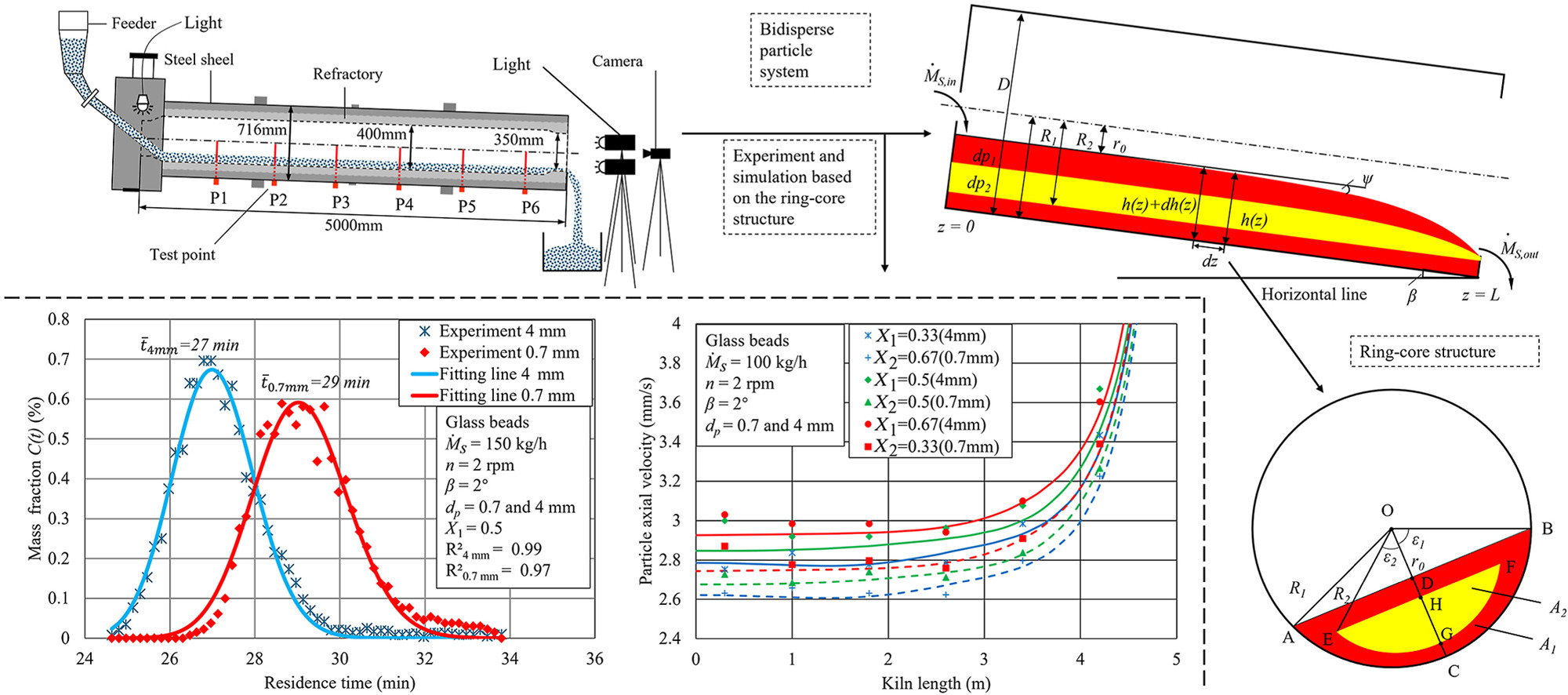

• Developed a model for predicting residence time and velocity of bidisperse particles in rotary kilns.

• Validated the model using pilot-scale tests with various size ratios and mass concentrations.

• Measured RTD, MRT, Dz, and Pe via tracer tracking and statistical methods.

• Achieved high model accuracy by comparing predictions with experimental data.

• Evaluated size and mixing effects by changing size ratios and mass concentrations.

In this study, a mathematical model based on the segregation-induced ring-core structure was developed to predict the residence time and axial velocity of particles of different sizes within a rotary kiln. Validation experiments were conducted using a pilot-scale rotary kiln with bidisperse particle systems comprising particle sizes of 0.7 mm, 2 mm, and 4 mm. The entire process was recorded using video analysis, which enabled the tracking of tracer particle movement from the inlet to the outlet. Based on the recorded data, the average axial velocity for each particle size across different kiln regions was determined. At the outlet, the tracer particles were analyzed using statistical methods and diffusion theory, allowing for the calculation of the residence time distribution (RTD), mean residence time (MRT), variance, axial dispersion coefficient (Dz), and Peclet number (Pe). The experimentally obtained MRT exhibited strong agreement with the predictions of the mathematical ring-core structure model, confirming its accuracy and reliability. Additionally, the influence of particle size and mixing behavior was systematically evaluated by varying particle size ratios and mass concentrations.