- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

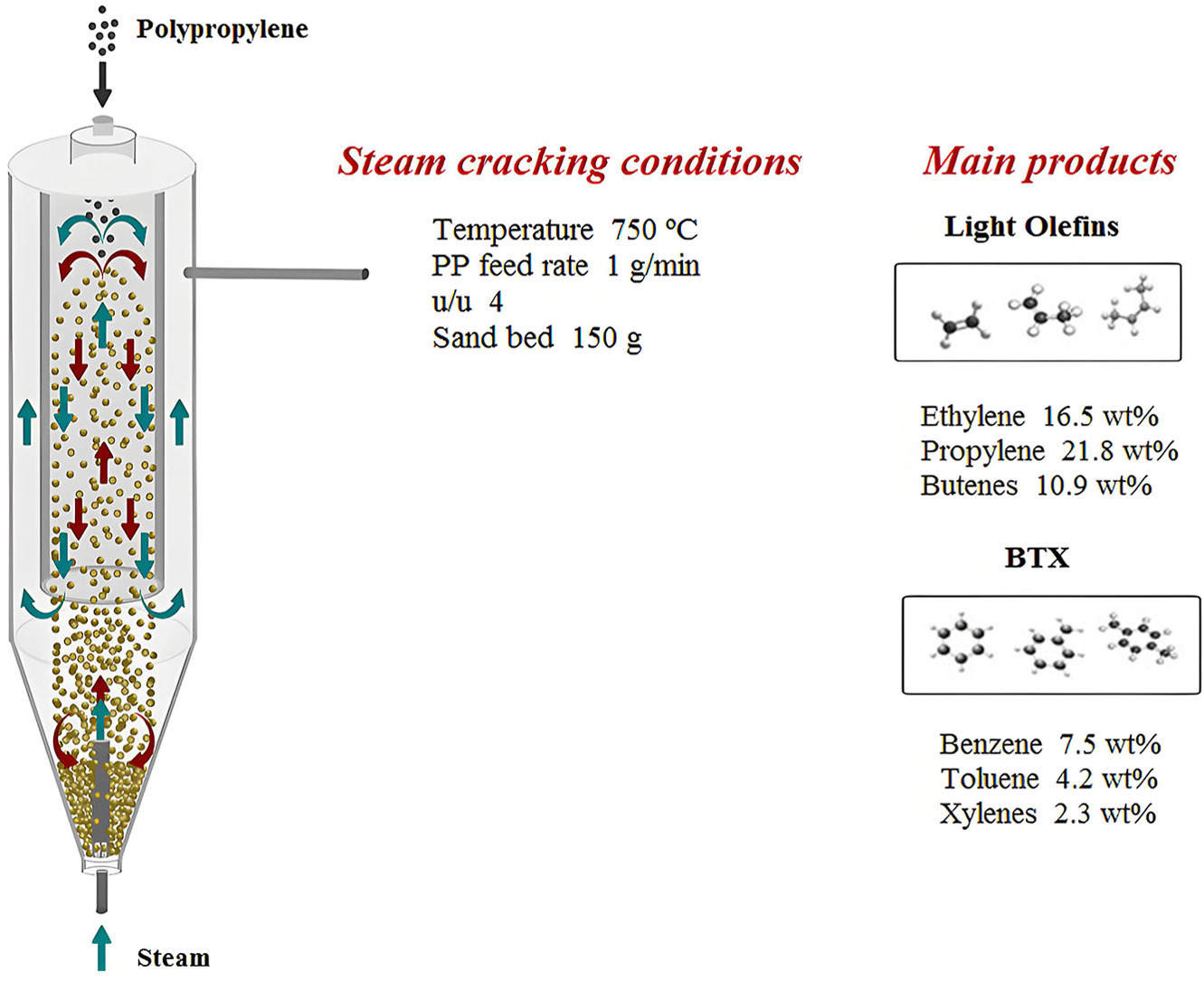

• Fountain confined conical spouted bed reactor is suitable for plastics steam cracking.

• Upcycling PP via steam cracking proves to be similar to naphtha cracking.

• Propylene and ethylene productions (21.8 and 16.5 wt%) were high at 750 °C.

• BTX fraction (14.0 wt%) was mainly composed of benzene (7.5 wt%).

This paper presents an alternative approach for plastic waste valorization in a fountain confined conical spouted bed reactor. The study evaluates the application of an upgraded spouted bed design for the steam cracking of polypropylene (PP) at 750 °C, focusing on high value added products. The highly efficient cracking process results in a high gas yield of 80.9 wt%. This stream is composed of H2, CO, CO2, C1-C4 paraffins and C2-C4 olefins, with the latter reaching a total yield of 49.2 wt%. Among the light olefins, propylene (21.8 wt%) and ethylene (16.5 wt%) are the most relevant. Interestingly, a remarkable yield of the valuable BTX fraction was obtained, 14.0 wt%, with benzene being the predominant compound. The reactor configuration and excellent control of process conditions enhanced light olefins yield by β-scission and radical mechanism, promoting the formation of light hydrocarbons, as well as minimizing secondary oligomerization and reforming reactions. This study is a proof of the viability of steam cracking in a fountain confined spouted bed reactor for converting PP into valuable chemical intermediates, as well as the viability of this technology for industrial application in waste plastic valorization.