- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

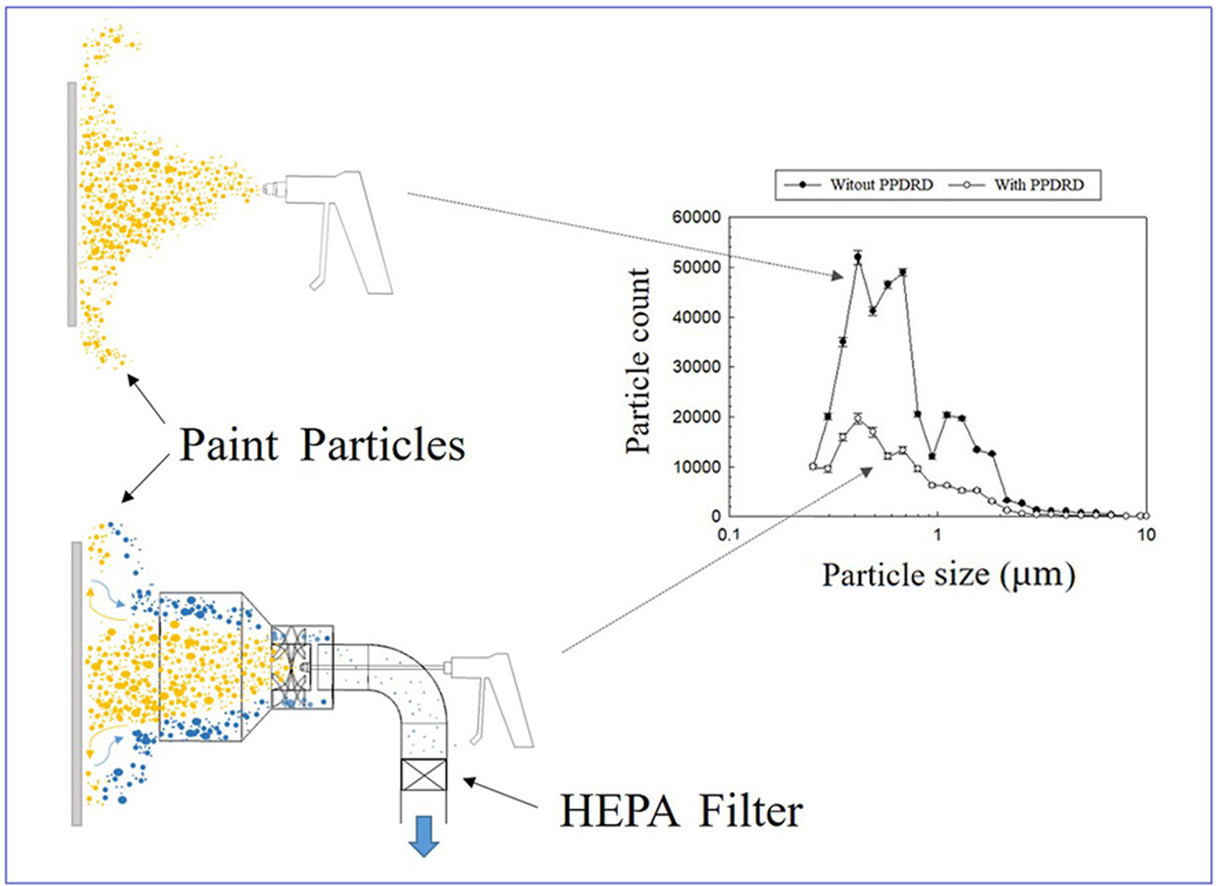

• A paint particle dispersion reduction device (PPDRD) was developed.

• PPDRD combined a cyclone separator and HEPA filter to capture dispersed particles.

• CFD simulations optimized design factors, including guide vanes and suction flow rate.

• Field tests showed a 50–80 % reduction in respirable paint particle dispersion.

• PPDRD is expected to reduce air pollution in various painting industries.

Airless spray painting, widely adopted for its efficiency and cost-effectiveness, generates a significant amount of airborne paint particles that contribute to air pollution and pose health risks to workers and nearby residents. In this study, a paint particle dispersion reduction device (PPDRD) utilizing an axial cyclone separator and a high efficiency particulate air (HEPA) filter was designed and evaluated to minimize the dispersion of paint particles during airless spray applications. The cyclone separator captured larger paint particles through centrifugal force, while the HEPA filter effectively removed smaller particles that escaped the cyclone separator. Computational fluid dynamics (CFD) simulations were conducted to optimize key design parameters, including the number and height of guide vanes and suction flow rate. Lab-scale and field experiments demonstrated that the PPDRD significantly reduced airborne paint particles, with respirable particles (4 μm or smaller) decreasing by 50–80 % depending on particle size, while maintaining coating quality. These findings indicate that the PPDRD effectively mitigates the inhalation risks associated with hazardous paint aerosols, providing a practical solution for improving workplace safety and environmental compliance. This technology is expected to be widely applicable in exterior building painting, shipbuilding, and the automotive industry.