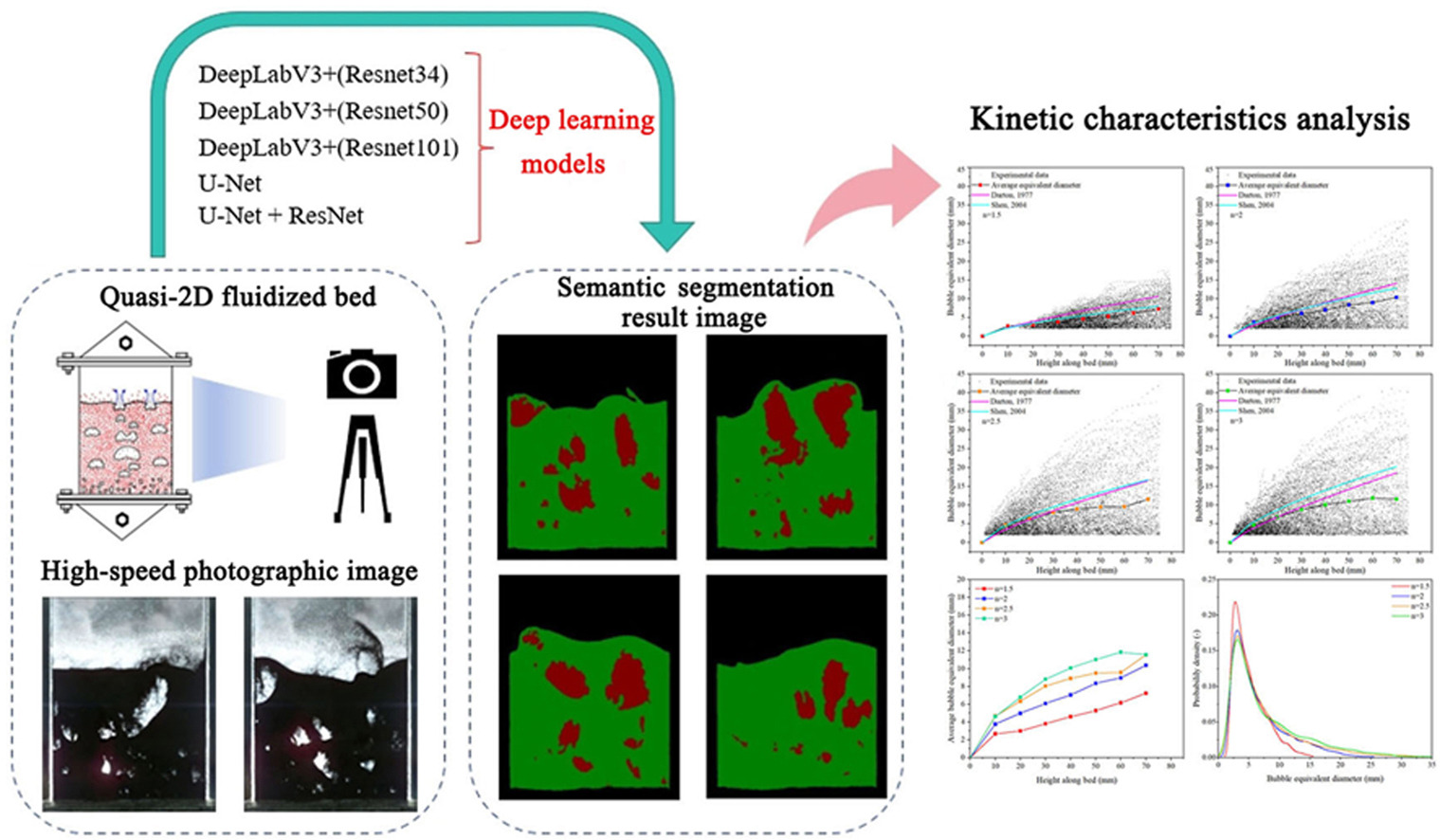

• Bubbles in gas-solid fluidized beds are difficult to be accurately observed.

• Identifying bubbles using deep learning methods.

• Compare five different deep learning models and find one with the best performance.

• Study on the kinetic characteristics of iron ore powder.

The dynamic characteristics of bubbles are pivotal for the design and optimization of gas-solid fluidized beds. Common techniques for bubble analysis include direct photography, Electrical Capacitance Tomography (ECT), and X-ray imaging, among others. Traditional image segmentation methods often struggle to accurately process a substantial number of digital images within complex background environments. This paper presents a deep learning-based semantic segmentation methodology specifically designed for bubble segmentation in gas/iron ore powder fluidized beds and assesses the segmentation performance of five distinct deep learning models. Based on training outcomes, the DeepLabV3+ model utilizing a ResNet50 backbone demonstrates superior performance. Building upon this optimal deep learning model, various kinetic characteristics of bubbles, including equivalent diameter, size distribution, aspect ratio, bed voidage, and rising velocity, are analyzed at different fluidization numbers (n = 1.5, 2, 2.5, 3) within a quasi-2D fluidized bed setup. The findings indicate that the fluidization number significantly affects the evolution of bubble size and equivalent diameter in the fluidized bed; notably, the average equivalent diameter tends to increase with height along the bed. Conversely, the influence of fluidization number on both bubble size distribution and aspect ratio distribution is relatively minor. As both fluidization number and height from the sieve plate increase, bed voidage rises while fluctuations intensify considerably. Furthermore, bubble rising velocity correlates positively with increasing equivalent diameter; however, it remains independent of fluidization number for bubbles of identical sizes.