• A simulation model was successfully validated to describe dry mixing cathode materials in Eirich intensive mixers.

• Increased filling height, vessel speed, mixing tool size and design were found to improve dry mixing.

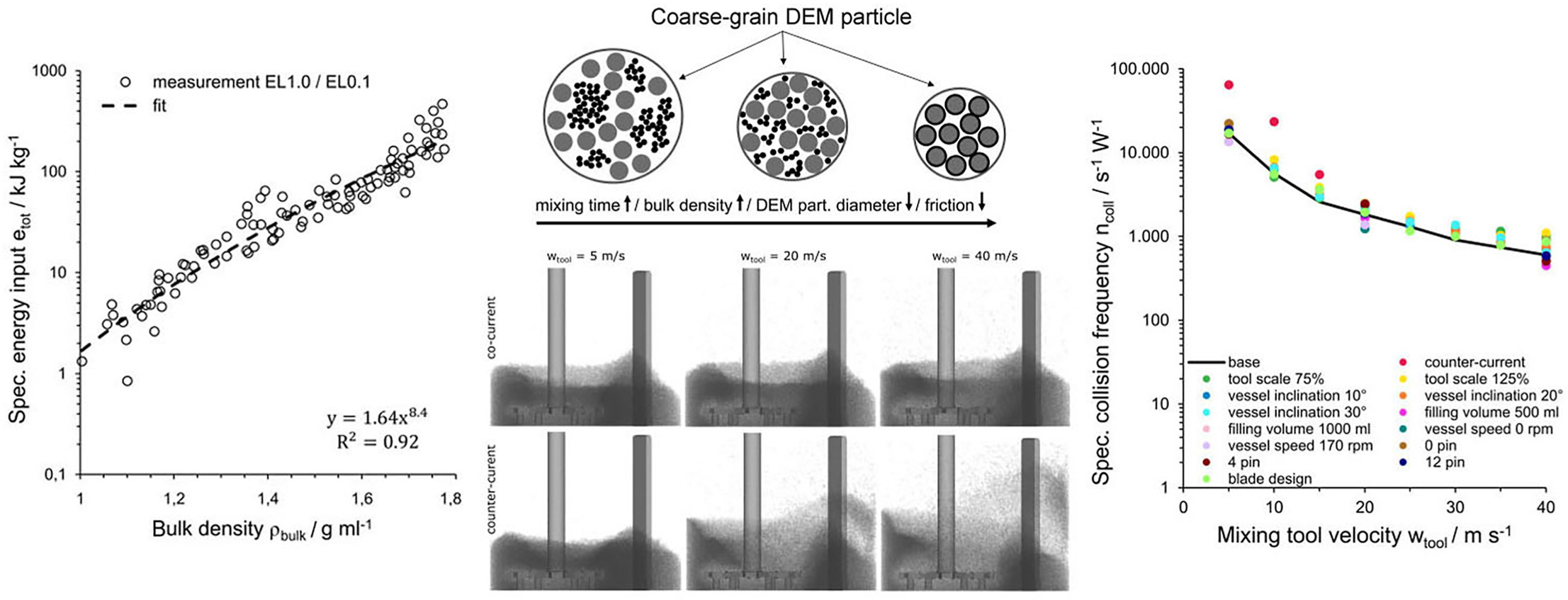

• While collision rates generally decrease with increasing mixing tool speeds, total collision energy increases.

• Degree of CB comminution can be described via the specific energy input and its effect on overall mixture bulk density.

• The mixing tool design can be optimized to reduce the process time and associated production cost during dry mixing.

This study uses the discrete element method (DEM) to investigate stress intensity in an Eirich EL1.0 mixer during the dry mixing of Li-ion cathode material. We find that the comminution of conductive additives depends on the specific energy input from the mixing tool, validated by particle size measurements using the Lumisizer method. The simulation model aligns well with experimental data, showing that impact stress from the mixing tool is the primary comminution mechanism. Homogeneity is achieved within 30 seconds, regardless of the mixing tool's speed, due to the vessel's rotation. Various operational modes were tested, revealing that counter-current operation is not significantly more effective than co-current operation above tool speeds of 20 m/s. Higher vessel speeds and fill levels increased collision frequency and energy dissipation, while the number of pins on the mixing tool had little impact, except at lower speeds. Adding six blades improved collision rates and energy dissipation, demonstrating the potential for optimizing the mixing tool design through DEM simulations and reducing battery production cost associated with dry mixing.