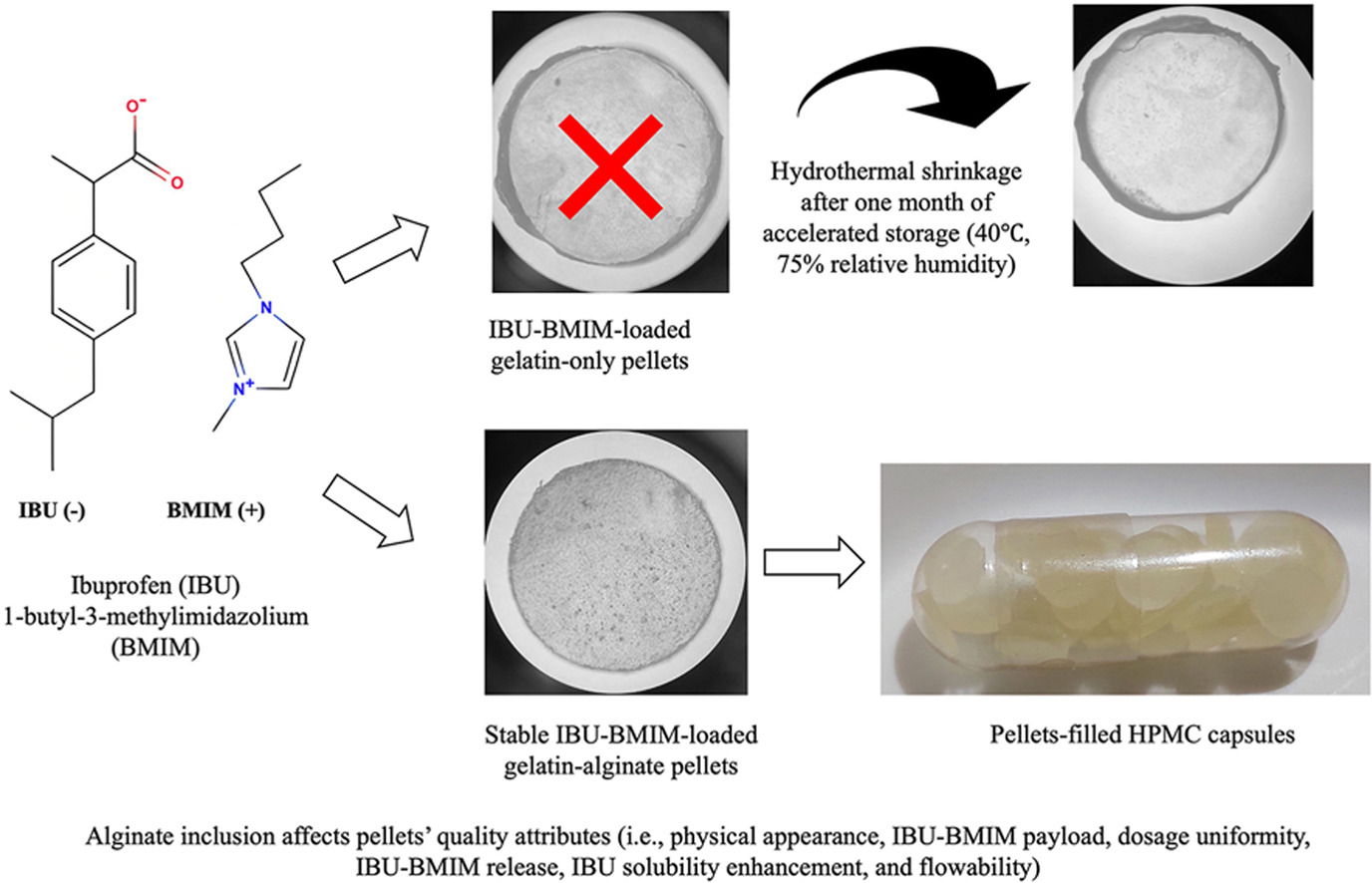

• Alginate affects pellets' quality attributes and gelatin secondary structures.

• Alginate inclusion improves pellets' flowability, slow IBU-BMIM release.

• IBU-BMIM maintains its liquid-like amorphous form in gelatin-alginate pellets.

• IBU-BMIM in pellets preserves its IBU solubility enhancement capability.

• Alginate inclusion stabilizes IBU-BMIM-loaded pellets during accelerated storage.

Ionic liquid (IL) salts of active pharmaceutical ingredients (API) represent promising formulations for poorly-soluble APIs as they eliminate polymorphism commonly associated with conventional API salts. Being highly viscous liquid, oral dosage formulation of API-ILs is challenging, necessitating immobilization onto particulate carriers, typically by spray-drying. This study developed an alternative oral dosage formulation of API-ILs by incorporating them into soft gelatin-alginate pellets, where the alginate's role was to improve storage stability of hygroscopic and thermally-sensitive gelatin. Poorly-soluble ibuprofen (IBU) and 1-butyl-3-methylimidazolium (BMIM) was used as the model API-IL. The impacts of alginate inclusion at varying gelatin-to-alginate ratios on quality attributes of IBU-BMIM-loaded pellets were investigated. The evaluated attributes included physical appearance, IBU-BMIM payload, dosage uniformity, flowability, IBU-BMIM release, and IBU solubility enhancement. The results showed IBU-BMIM remained in its liquid-like amorphous form upon incorporation into the pellets, thereby preserving its solubility enhancement capability, albeit at a lower degree due to slower IBU-BMIM release upon alginate inclusion. Alginate inclusion also influenced the pellets' physical appearance, thickness, flowability, and gelatin's secondary structures, while having minimal impacts on payload and dosage uniformity. Importantly, the pellets remained stable after one-month of accelerated storage (40 °C and 75 % relative humidity) with minimal variations in their quality attributes.