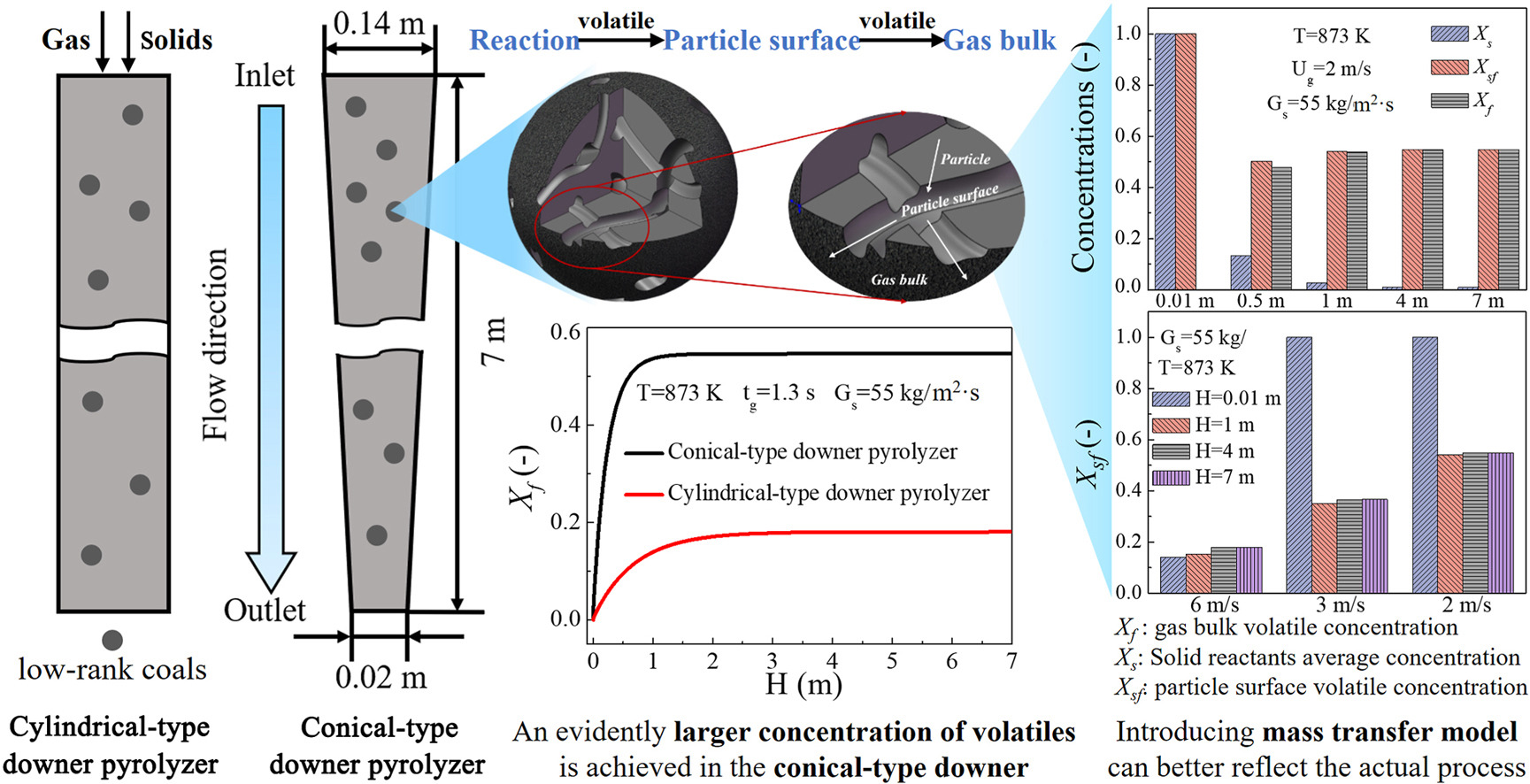

• Coal pyrolysis in a novel conical-type downer pyrolyzer is firstly simulated.

• Discrete-DAEM kinetics is adopted to compromise the precision and efficiency.

• A multi-scale mass transfer model is introduced to better reflect the actual process.

• Integrated multi-scale mass transfer model with discrete-DAEM simulates coal pyrolysis.

• Potential advantages of conical-type downer pyrolyzer are verified by simulation.

The performance of a novel conical-type downer pyrolyzer is carefully evaluated via numerical simulation. The study explicitly accounts for mass transfer effects by using a multi-scale mass transfer model. To achieve simultaneous high precision and computational efficiency, an enhanced strategy for calculating the multi-scale mass transfer coefficient in heterogeneous phase reaction systems is proposed by treating mass transfer and reaction as independent processes. This strategy is coupled with a discrete distributed activation energy model formulated in the Arrhenius framework. A comprehensive analysis is performed to investigate the axial distributions of key parameters, including the average concentration of solid reactants (Xs), the volatile concentration on particle surfaces (Xsf), and the volatile concentration in the bulk gas phase (Xf) under varying pyrolysis temperatures, carrier gas velocities, and solid mass fluxes. The findings reveal that Xs and Xf exhibit intuitive, monotonic trends, while Xsf demonstrates a more complex behavior, increasing due to ongoing reactions yet decreasing with mass transfer proceeding. The simulation results verify the advantages of the conical-type downer pyrolyzer, which can achieve significantly higher volatile concentrations than conventional designs.