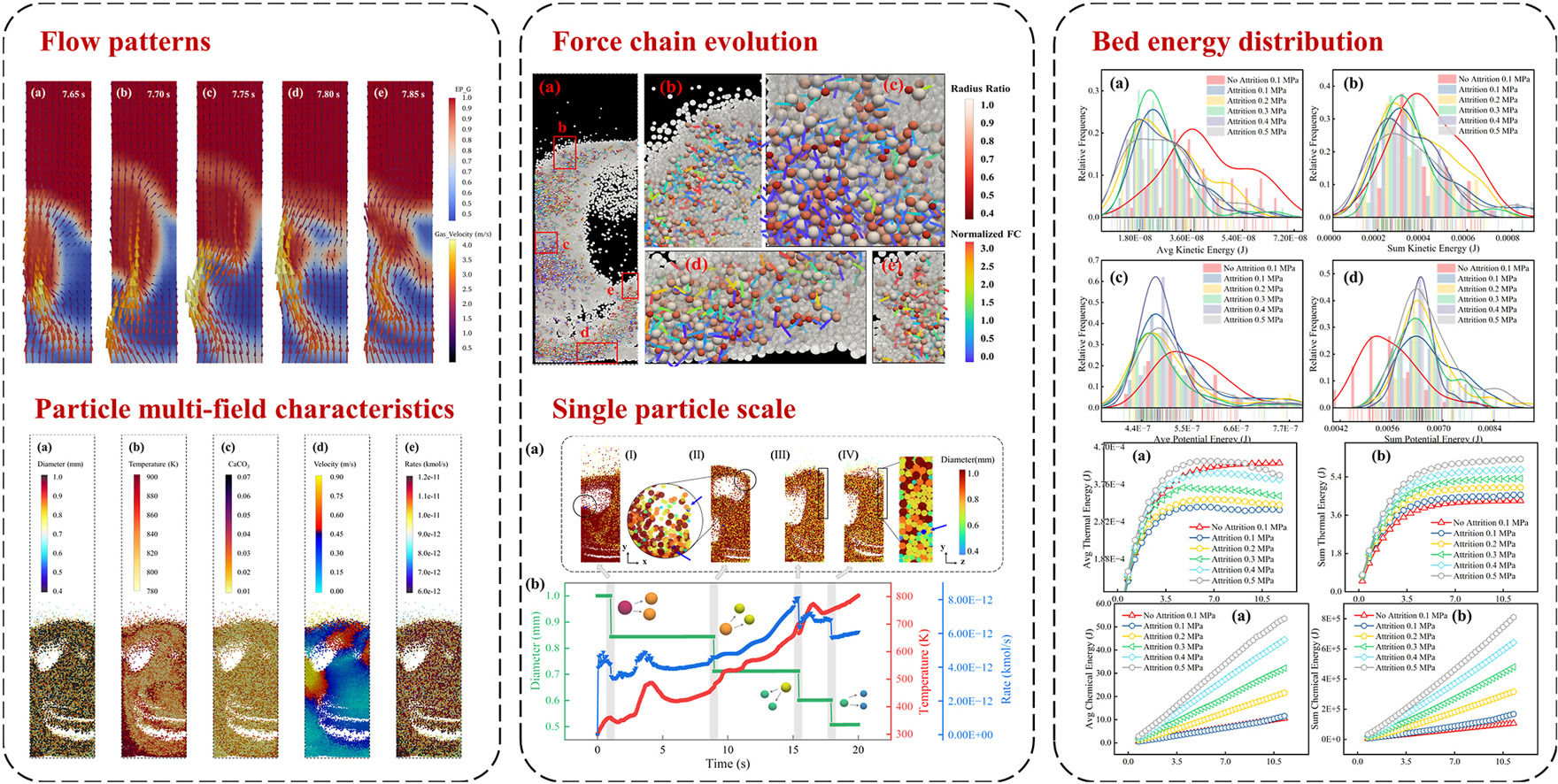

• Integrated attrition model involves mechanical-thermal-reaction used in thermochemical energy storage simulation.

• Breakage particles form multi-level force chain network, but weakening local chains.

• Wear and breakage increase both reaction rate and bed energy unevenness.

• Pressure and velocity accelerate the energy storage conversion process.

Due to advantages such as rapid heat transfer and thorough mixing, fluidized bed reactors have become highly efficient systems for energy storage processes. However, under high temperatures and reactive conditions, severe particle attrition alters both the temperature response characteristics of the bed material and the gas–solid fluidization behavior, which impacts energy storage cycles. This study simulates the multi-field coupling characteristics of an energy storage fluidized bed reactor under attrition conditions, analyzing particle force chains, individual particle reactions, heat transfer, and the effects of operating parameters on energy distribution. The results indicate that particle attrition generates small particles within the bed, leading to uneven temperature and chemical energy distribution. The force chain network becomes more complex yet weaker, reducing the bed's mechanical stability. Increased surface area from particle breakage enhances thermal exchange with the gas, causing an initial rise in reaction rate, which then decreases as local reactants are depleted. Operational parameters such as operating pressure, gas temperature, and inlet velocity significantly impact energy release. These findings provide a theoretical basis for the design and optimization of energy storage fluidized bed reactors.