-

Volumes 96-107 (2025)

-

Volume 105

-

Volume 104

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 105

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

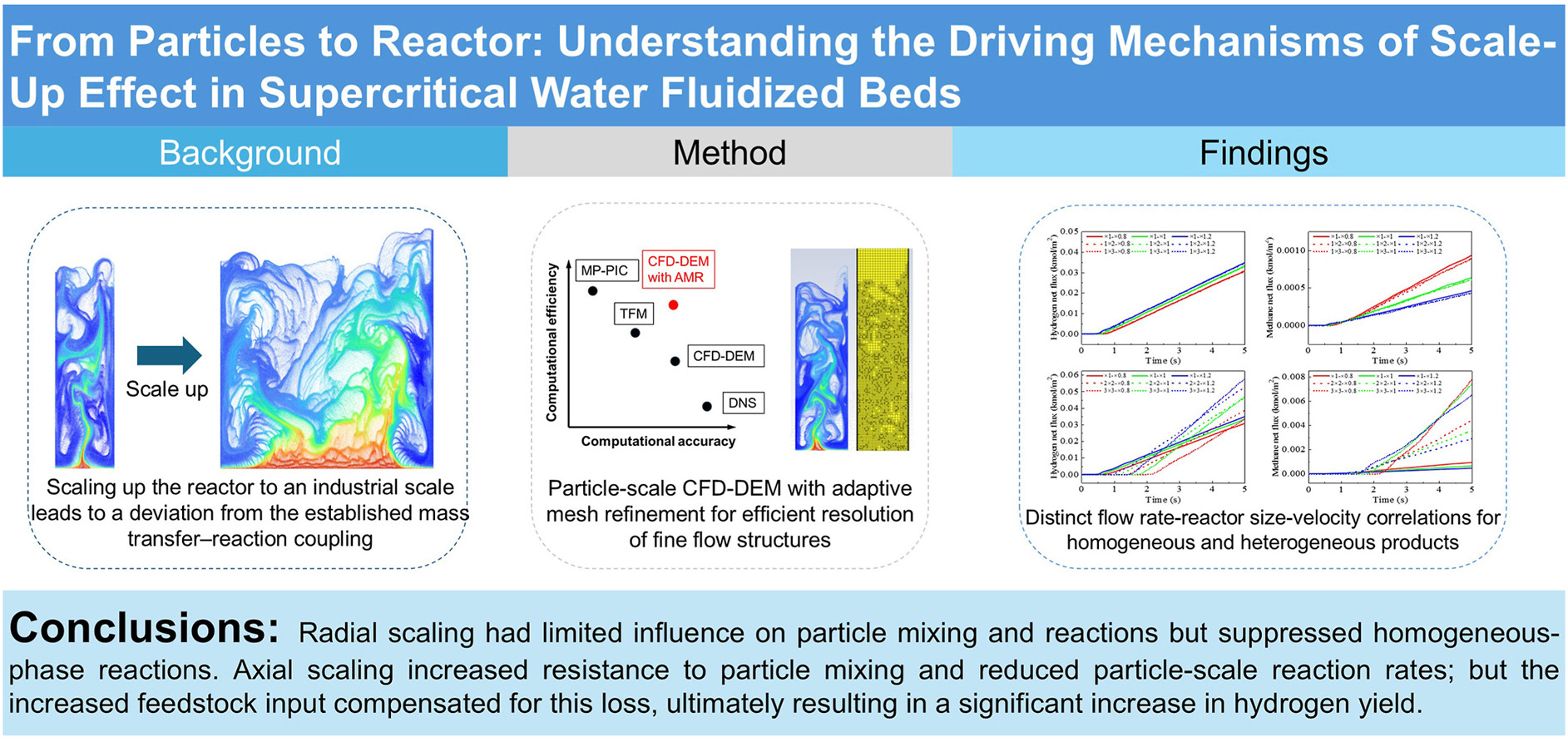

•A high-resolution model was employed to track detailed particle-scale flow behavior.

•The model integrated adaptive mesh refinement to enhance computational efficiency.

•Driving mechanisms behind the reactor scale-up effect were revealed.

•Radial and axial scaling affect reactor performance through different mechanisms.

Supercritical water gasification is a promising method for efficient hydrogen production. Among various reactor designs, fluidized bed reactors demonstrate strong industrial potential due to their plugging resistance and favorable hydrodynamic properties. However, scaling up the reactor to industrial applications disrupts the mass transfer-reaction matching relationship established at the particle level, making it challenging to replicate the performance of smaller reactors. To mitigate the scale-up effect of the reactor, a fundamental understanding of particle-scale mechanisms is essential. In this study, high-resolution numerical simulations are employed to investigate particle dynamics across both reactor and particle scales. To enhance computational efficiency, adaptive mesh refinement and heterogeneous computing are utilized. The scale-up laws governing the internal flow structures and chemical reaction performance within the reactor are analyzed. The temperature, diffusion, and chemical reaction performance at the particle level are tracked, and statistical analyses are performed to elucidate the mechanisms driving the scale-up effects. Results reveal that the two scaling approaches affect reactor performance through different mechanisms. Radial scaling has minimal impact on particle mixing and reaction rates, whereas axial scaling reduces particle reaction rates; however, this reduction is compensated by an increased particle count, ultimately enhancing overall hydrogen yield. Additionally, higher superficial velocity enhances feedstock mixing and thermal uniformity, resulting in more uniform particle reactions, although it may hinder homogeneous reactions. These findings offer new insights into reactor scale-up effects and hold promise for guiding optimal and detailed design of future industrial-scale reactors.