-

Volumes 96-107 (2025)

-

Volume 105

-

Volume 104

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 105

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

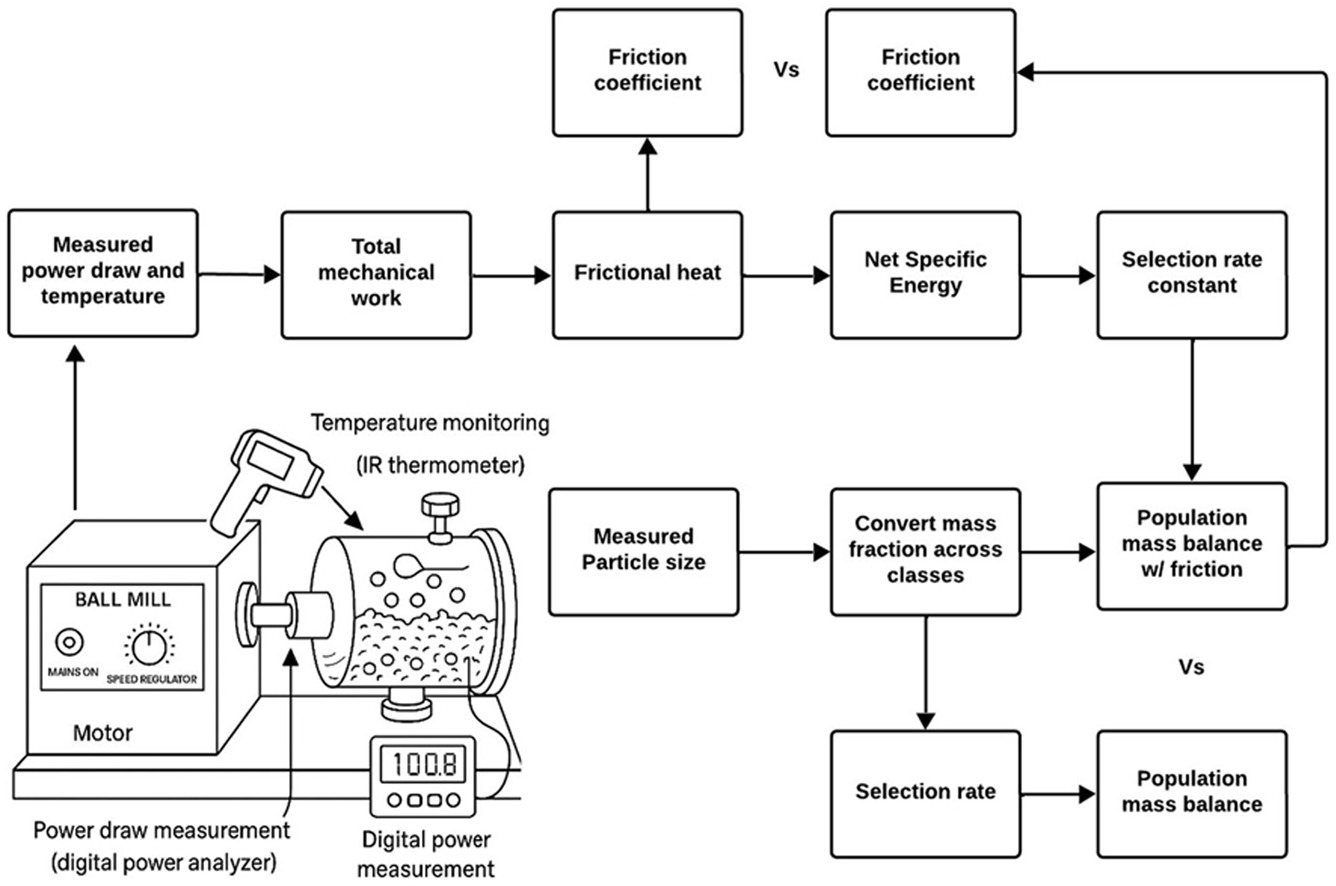

• Friction-coupled PBM clarifies net breakage energy for efficient rice bran milling.

• Early fragmentation transitions to a fine-dominated regime with slower comminution.

• Short, high-speed milling yields moderate fineness at lower energy consumption.

• Extended milling achieves sub-5 μm sizes but at steep power penalties near 5 kWh/ton.

• Friction-aware PBM surpasses classical laws, enabling robust milling optimization.

Despite rice bran's considerable nutritional and functional potential, its fibrous structure and high oil content complicate efforts to produce uniform, finely milled powders for food and nutraceutical applications. This study addresses that challenge by examining how milling time (30–90 min) and rotational speed (30–120 rpm) influence both the extent of particle size reduction and the associated energy demand. A laboratory ball mill was used to generate a broad range of operating conditions, while mechanical energy usage and particle-size parameters (d10, d50, d90) were recorded. Population Balance Modeling (PBM) served as the primary analytical framework, calibrated through experimental size distributions to yield breakage kinetics. Frictional effects were incorporated to determine net breakage energy, and classical comminution laws (Bond, Rittinger, Kick) were also evaluated for benchmarking. Results revealed two key milling regimes: an early stage with rapid fragmentation of larger particles, followed by a fine-dominated phase marked by diminished breakage rates and agglomeration. Friction-coupled PBM simulations achieved near-unity parity with experimental data, significantly improving upon simplistic energy models. Short, high-speed milling (e.g., 30 min at 120 rpm) delivered moderate fineness (d50 ≈ 70–90 μm) at relatively low energy (≈0.002–0.005 kWh/ton), whereas prolonged milling (≥90 min) could push median sizes below 5 μm but escalated energy consumption (∼5 kWh/ton). These findings highlight the trade-off between achieving ultra-fine bran and managing rising power costs. By integrating friction-coupled PBM insights with empirical measurements, the study provides a rigorous basis for multi-objective process optimization, guiding industrial-scale rice bran milling toward both enhanced product quality and improved energy efficiency.