-

Volumes 96-107 (2025)

-

Volume 105

-

Volume 104

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 105

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

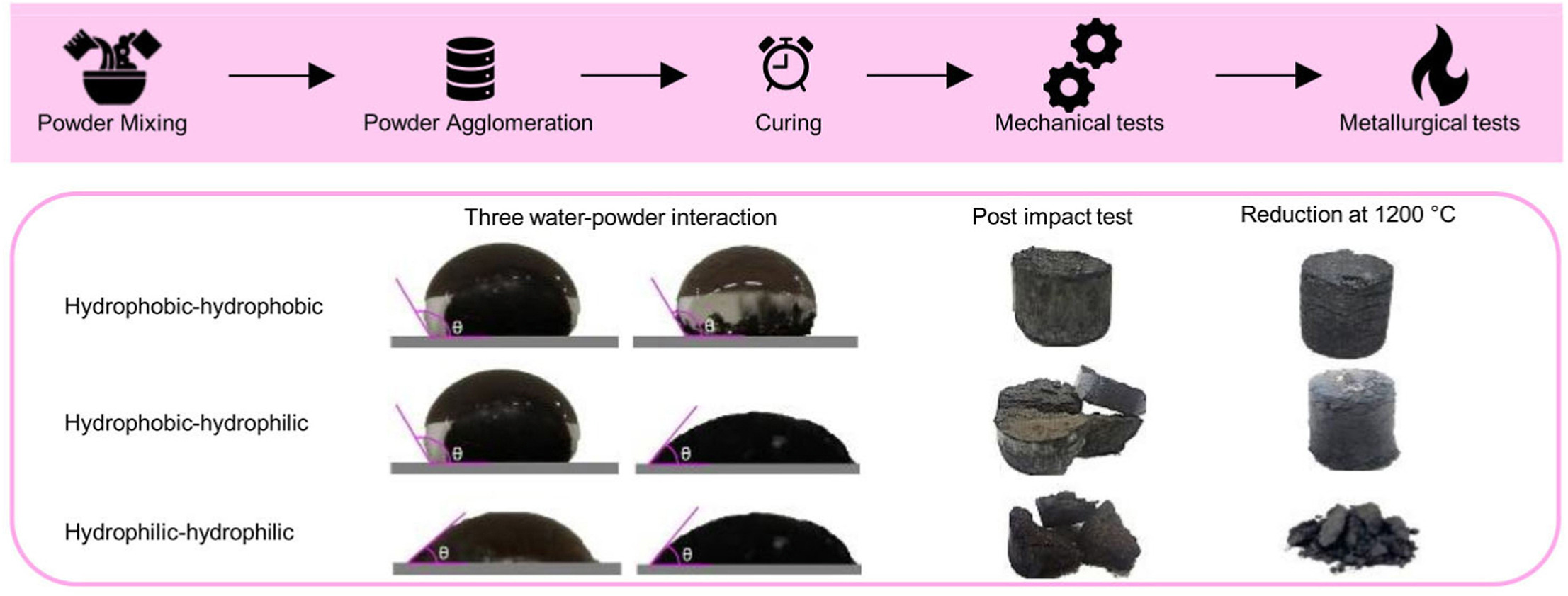

• Water expulsion from hydrophobic powders improved briquette's impact resistance.

• Hydrophilic-hydrophilic briquettes showed the best metallurgical performance.

• Hydrophilic powders increased reduction but caused catastrophic swelling.

• Optimized water content doubled mechanical resistance and reduced swelling issues.

In 2023, 1888 Mt of steel were produced worldwide, with 70 % via integrated cycle steel plant, generating 34 Mt of dust and 25 Mt of sludge. These wastes are rich in Fe and C but are too fine for direct recycling. Agglomeration is therefore essential to recycle them as suitable feedstock. This work studies how water–powder interactions affect the mechanical (impact resistance, cold compressive strength) and metallurgical (degree of reduction, swelling) properties of self-reducing briquettes made by combining two iron-bearing dusts (BOF dust and a secondary dust) with two reducing agents (BF sludge and another secondary dust) to form hydrophilic–hydrophilic, hydrophobic–hydrophilic, and hydrophobic–hydrophobic mixtures. Water expelled from hydrophobic dust acts as a lubricant during compaction, reducing surface cracks and enhancing eight times the impact resistance. Hydrophilic particles, however, lower impact resistance (failing 10-drop tests) due to hydration repulsion that weakens the briquette. While water absorbed by hydrophilic powders forms gasification channels on drying, enabling a reduction degree up to 94 %, it also causes severe swelling below 1200 °C. The best overall performance was achieved by a hydrophobic–hydrophilic combination with double water content, yielding compressive strength of 18 MPa, degree of reduction of 91 % and swelling of −1.86 %.